to construct the line. Because velocity, grain structure,

and other properties of the CRA material differ from the

parent material, these types of manufacturing and assembly

processes raise new challenges in the inspection strategies of

pipeline girth welds.

CRA-clad pipeline inspection challenges

Ultrasonic inspection of dissimilar girth welds in CRA-clad

piping poses a particular challenge. As the material of the

clad layer (Inconel, stainless steel, etc.) differs from that of

the parent material (carbon steel), the characteristics of the

interface between these materials makes the pulse rebound

on the internal wall (ID) of the pipe unpredictable or even

unusable. In addition, the anisotropic structure of the cladding

and the weld creates ultrasonic mode conversion and erratic

beam orientations. Consequently, high precision techniques

such as zone discrimination cannot be used. Pulse-echo testing

using the second leg of the ultrasonic beam is impossible,

which makes inspection of the cap and its subsurface

extremely challenging.

CRA-clad pipeline inspection solution

The solution developed for CRA-clad inspection is based on

the use of dual linear arrays (DLA). Coverage of the full volume

and surface of the weld can be obtained by performing a

sectorial scan with DLA probes using longitudinal waves (LW).

A DLA probe is basically a dual element probe, though

with one linear array as the transmitter and one linear array

as the receiver, separated by acoustic insulation. This dual

configuration eliminates interface echoes, as well as dead

zones resulting from wedge echo, and it generates more

energy and less noise in the inspection data. This optimised

configuration inspects the surface and volume with the same

probe and wedge, ensuring full coverage. When mounted

on a fully automated scanner, two dual linear array probes

(one positioned on each side of the weld) are capable of

performing the inspection in only one pass.

The weld is separated into different zones: the root, the

volume, and the upper area (including the cap). The DLA probe

inspects the volume with longitudinal waves that penetrate

the weld, interrogating the opposite portion of the weld, to

identify lack of fusion at the weld bevel. High angle LW and

surface waves interrogate the upper part of the weld, including

the surface, while the root is inspected with lower LW angles.

All these angles are grouped together into one easy-to-read

view called a sector scan.

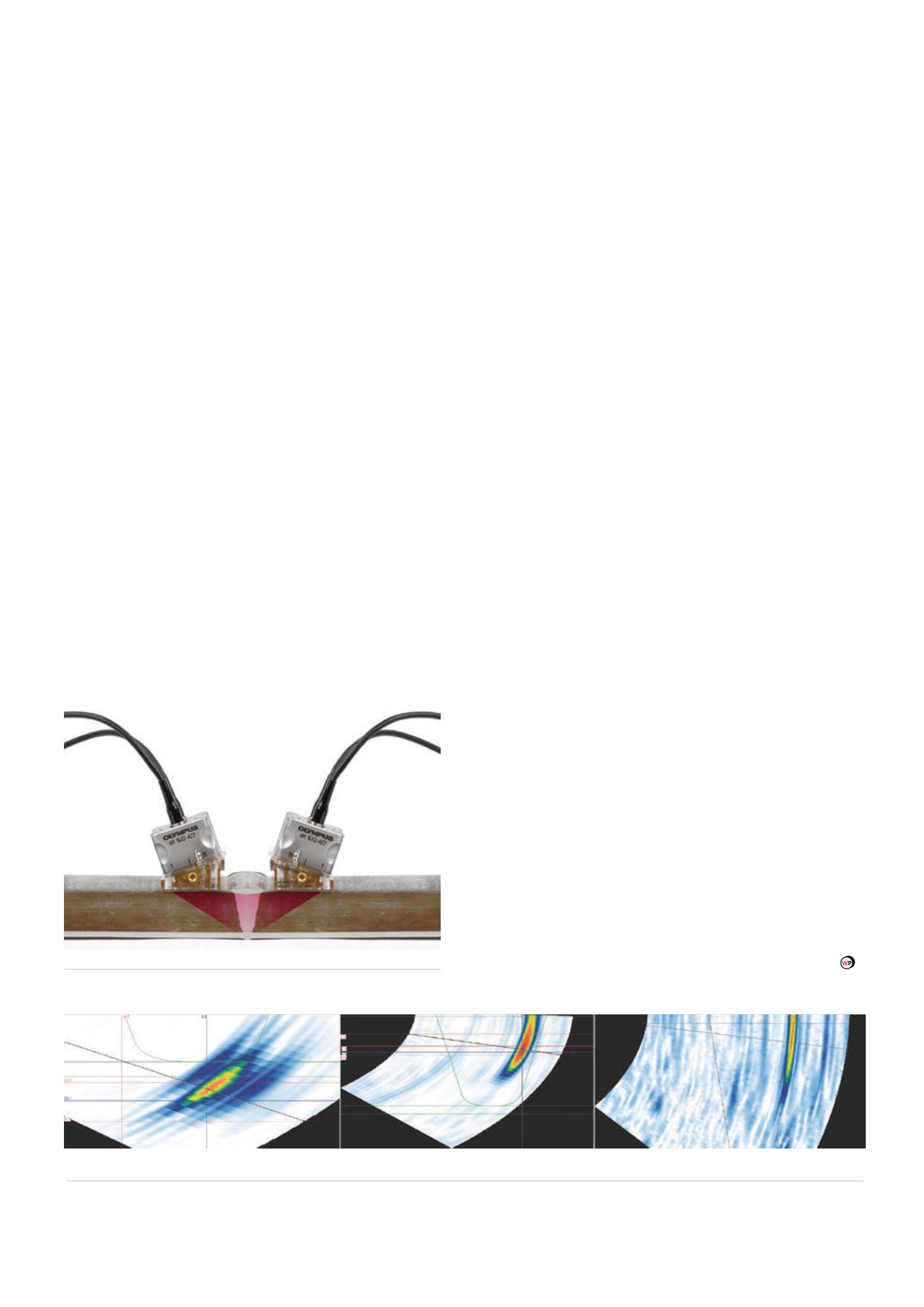

Optimised DLA configurations have been tested on

different pipe configurations with different clad types and

thicknesses. In Figure 4, the DLA probe has detected flaws

located at the weld root position, at the weld bevel, and a

surface notch located in the upper portion of the opposite

side of the weld. In all of these cases, detection was achieved

while the ultrasonic beams travelled through the weld.

Generally, the DLA configuration has the capability to

penetrate the weld with minimal distortion, enabling full

inspection of the weld. However, it is important to test and

optimise the inspection for the pipe configuration to be

inspected.

Conclusion

Recent progress in the development of AUT techniques

addresses challenging applications such as CRA-clad pipeline.

The use of dual linear arrays increases the penetration of

ultrasonic beams in dissimilar girth welds, enabling full

inspection of the weld, from the root to the surface, with

only two DLA probes. Combined with high performance

instrumentation and easy-to-comprehend software imaging,

DLA eases the work of the operator and brings all the

advantages of AUT to this industry.

New advanced ultrasonic techniques contribute

significantly to the integrity of pipelines. When used during

pipeline construction, these techniques optimise the accuracy,

speed and reliability of ultrasonic inspection.

In addition, these techniques have shown to be reliable

replacements for radiography in ensuring pipeline integrity.

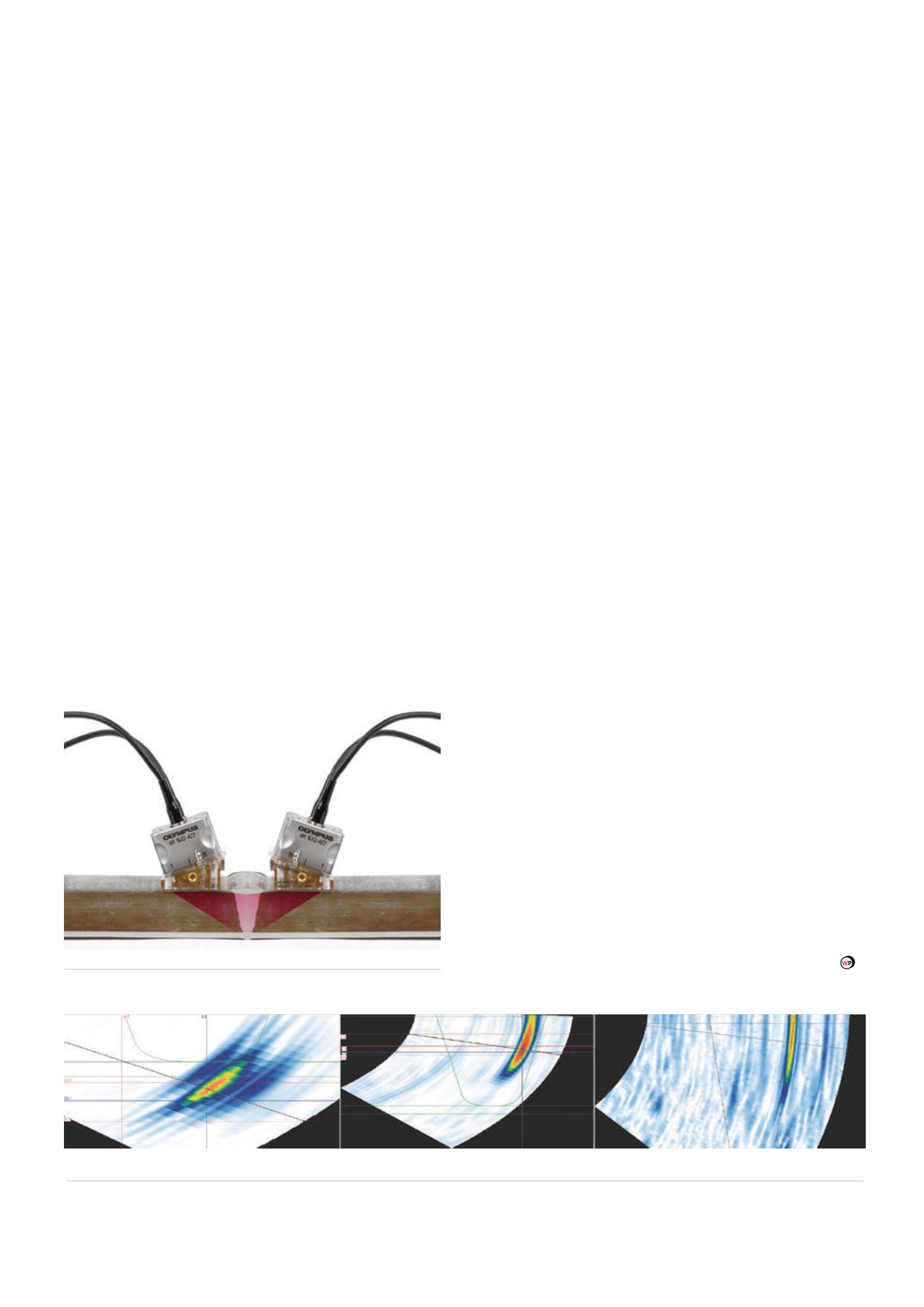

Figure 3.

Olympus dual linear array probe configuration.

Figure 4.

Sector scan imaging of flaws in the root, the weld bevel, and the cap.

124

World Pipelines

/

AUGUST 2015