)

)

Hoey and Cohen

3

: “the corrosion rate is not reduced to

negligible values, although nominally near 1 mil/yr over

temperatures from 75 - 198˚F.”

)

)

AGA’s Interim Report

4

: Includes “polarised potential…to obtain

a corrosion rate of 1 mil/yr”; and, at the bottom of Page ES-2,

“regarding the criteria, assuming protection has been achieved

with a corrosion rate of 1 mil/yr.”

100 mV of cathodic polarisation

This research adopted the same definition of effective CP. Some

of the more significant examples follow:

)

)

AGA’s five year study on polarisation of coupons

4

: “the general

corrosion rates were typically less than…1 mil/yr.”

)

)

Zdunek and Barlo

5

: “…found that the amount of polarisation

required to reduce the corrosion rate to (1 mil/yr)” and the

plot of the “effect of temperature on the level of polarisation

for (1 mil/yr) corrosion rate.”

Therefore, if effective CP can be demonstrated throughout a

pipeline segment by close interval potential survey (CIS), coupon

data, or other means, then it is appropriate to use a growth rate of

1 mil/yr going forward. It is required that the contributing factors

to the observed metal loss have been identified during root cause

analysis and effectively mitigated. The projected corrosion rates

may also be applied to locations that have not been directly

examined, but which are subject to the same influences.

It is important to note that achieving the 1 mil/yr growth

rate expected with effective CP might not be the appropriate

objective for all pipelines. Factors such as the condition, critical

function, age, and intended service life of a specific pipeline

will affect the corrosion rate that can be tolerated and must be

considered.

Locations with ineffective CP

Where effective CP cannot be established but the corrosivity

of the soil environment may be adequately represented by

its resistivity, alternative methods must be used to estimate

corrosion rates. ASME’s B31.8S is among the most commonly used

guidelines for estimating corrosion rates based on soil resistivity.

ASME B31.8S

The text of ASME B31.8S

6

states that environmental characteristics

such as soil resistivity should be measured during direct

examinations. This document further states that this data “can be

used to estimate corrosion rates” (Table 1).

However, no technical support for these values is offered;

and there is no reference to the source of this table. Immediately

following the table, it is stated that, “If the operator can provide a

sound technical basis for using other corrosion rates or estimates

based (on) direct examination measurements, the actual rate can

be used in-lieu of those shown in the above table.” Furthermore, it

appears unreasonable to assign a corrosion rate as great as 3 mil/

yr to a site where soil corrosivity would typically be classified as

non-corrosive (no active corrosion).

NACE International

Peabody’s Control of Pipeline Corrosion

7

includes Table 2. The

consumption rate of pipeline steel is 20 lb per ampere-year. Based

on a density of 7.89 g/cm

3

, the corrosion rate conversion factor

is 1 microampere/cm

2

= 0.454 mil/yr. It is reasonable to assume

that the range of protective current requirements must be at least

as large as the anticipated corrosion currents for the conditions

described. Therefore, the corresponding corrosion rates have been

calculated (Table 3).

Comparison with the values presented in Table SP-B1 from

B31.8S (Table 1) suggests that the ASME rates are excessively

conservative. The B31.8S corrosion rate for high resistivity soil with

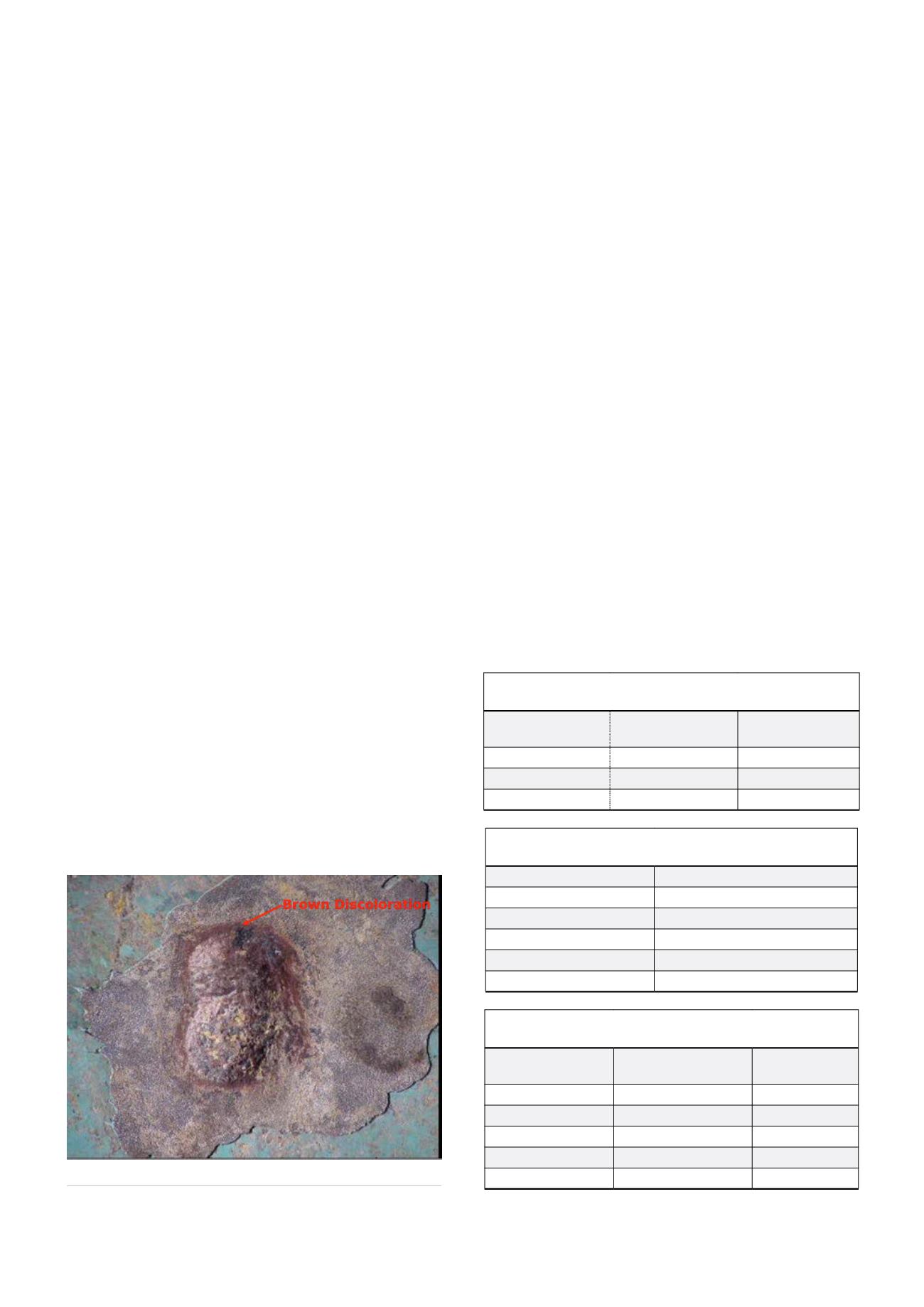

Table 3. Estimated current requirements for CP of steel and

corrosion rates (adapted from Peabody, p. 499)

7

Conditions affecting

bare steel

Protective current

required (mA/m2)

Corrosion rate (mil/

yr)

In moving seawater

100 - 160

4.54 - 7.264

In quiet seawater

55 - 85

2.497 - 3.859

In earth

10 - 30

0.454 - 1.362

Table 4. Effect of resistivity on corrosion (excerpted from

FHWA-NHI -00-044, p. 9)

8

Aggressiveness

Resistivity (OHM-CM)

Very corrosive

<

700

Corrosive

7000 - 2000

Moderately corrosive

2000 - 5000

Mildly corrosive

5000 - 10 000

Non corrosive

>

10 000

Table 5. Effect of resistivity on corrosion (adapted from FHWA-

NHI -00-044, p. 9)

8

Aggressiveness

Resistivity (OHM-CM)

Corrosion rate

(mil/yr)

Very corrosive

<

700

<

2.43

Corrosive

7000 - 2000

<

1.95

Moderately corrosive 2000 - 5000

<

1.56

Mildly corrosive

5000 - 10 000

<

1.25

Non corrosive

>

10 000

1

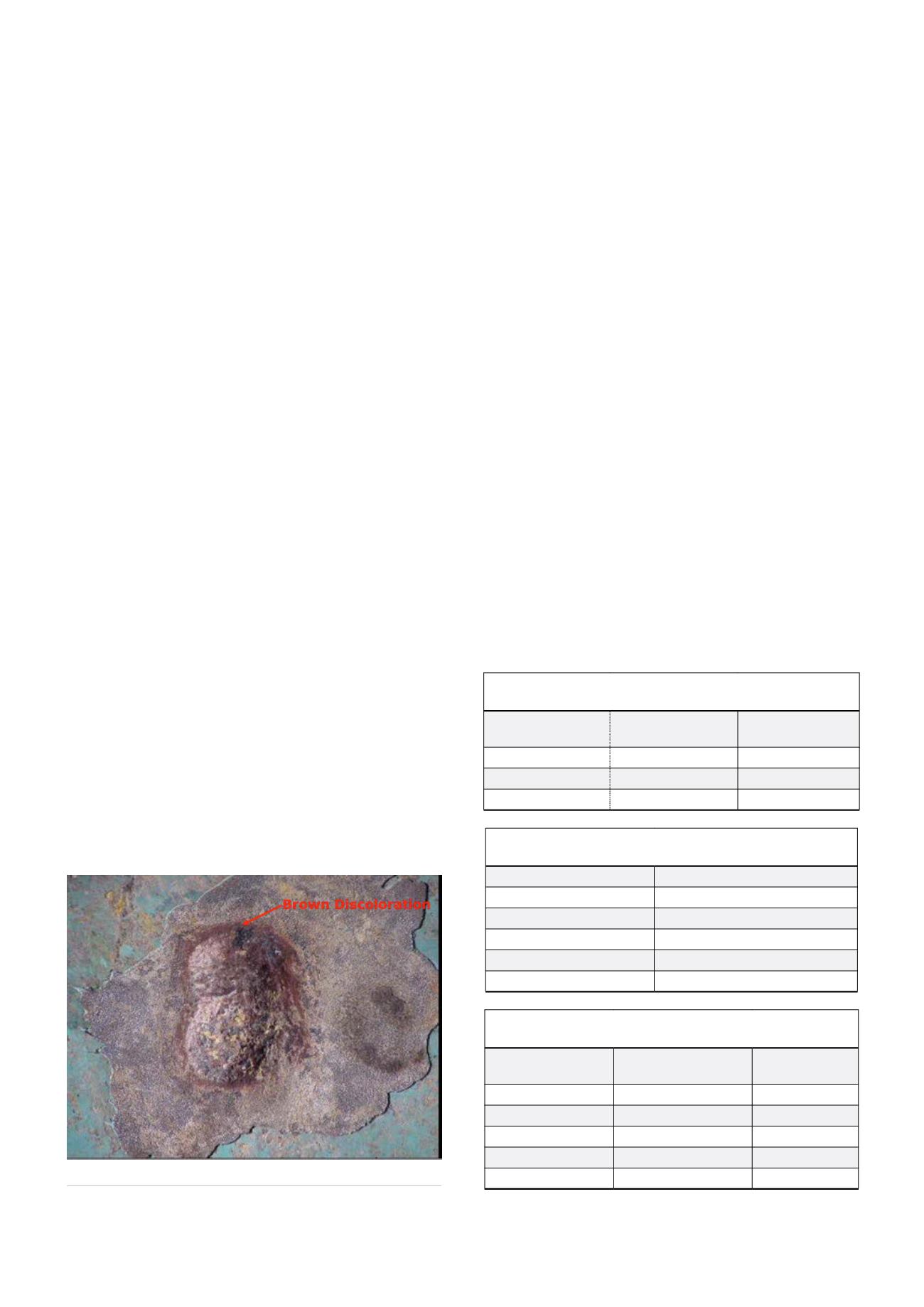

Figure 3.

A-C stray current corrosion.

116

World Pipelines

/

AUGUST 2015