no active corrosion would correspond to the behaviour of steel in

quiet seawater, rather than in soil; and the worst-case rates in low

resistivity soil are greater than those in moving seawater.

USDOT and NBS

In USDOT Publication No. FHWA-NHI-00-044, Corrosion

Degradation of Soil Reinforcements for Mechanically Stabilised

Earth Walls and Reinforced Soil Slopes

8

, Effect of Resistivity on

Corrosion, is presented here as Table 4. These classifications of

aggressiveness categories are similar to those used throughout

the corrosion control industry. In the original document, the

text immediately following this table states, “from the National

Bureau of Standards (NBS) data...a rough estimate can be made

that suggests corrosion rates are roughly increased by 25% in

each successive aggressiveness range, all other conditions being

essentially equal.” Accordingly, the values in the corrosion rate

column of Table 5 have been calculated, beginning with the

industry accepted definition that the corrosion rate in a ‘non

corrosive’ environment must be less than 1 mil/yr.

Comparison with the values presented in Table 1 suggests that

the ASME rates are excessively conservative. Again, the B31.8S

corrosion rate for high resistivity soil with no active corrosion is

greater than the calculated corrosion rate in the most aggressive

category from Table 5.

Summary

Accurate root cause analysis is critical for any metal loss observed

during direct examinations. Where the factors that contributed to

the metal loss have been or can be successfully mitigated (such as

by effective cathodic protection), substantial technical validation

exists to support the use of a corrosion rate no greater than 1 mil/

yr for estimating pit growth.

In the absence of documented compliance with SP0169, or

when other factors identified by root cause analysis have not been

adequately addressed, the guidelines of B31.8S may be used to

estimate corrosion growth rates.

The commonly-used guidelines for estimating corrosion

rates based on soil resistivity are excessively conservative and

are not adequately justified with supporting data. Where root

cause analysis identifies soil corrosion as the dominant corrosion

mechanism, B31.8S permits the use of other corrosion rates with

a sound technical basis. The calculated corrosion rates in Tables

3 and 5, based on the Peabody and DOT/NBS data, suggest that

a reasonable maximum corrosion rate in relatively uniform soils

would be approximately 2.5 mils/yr.

References

1.

SCHWERDTFEGER, W. J., and MCDORMAN, O.N., National Bureau of Standards,

‘Potential and Current Requirements for the Cathodic Protection of Steels in Soils’

Corrosion 8, 11, 1952.

2.

THOMPSON, N. G., and BARLO, T. J., ‘Fundamental Process of Cathodically Protecting

Steel Pipelines’, International Gas Research Conference, 1983.

3.

HOEY, G. R., and COHEN, M., ‘Cathodic Protection of Iron in the Temperature Range of

25-92˚C,’ Corrosion 14, 4, 1958.

4. BARLO, T.J., American Gas Association Interim Report, PR-151-163, ‘Field Testing the

Criteria for Cathodic Protection’, 1987.

5.

ZDUNEK, A.D., and BARLO, T.J., ‘Effect of Temperature on Cathodic Protection Criteria’

Materials Performance 31, 11, 1992.

6. DRAKE, J. A. et al, American Society of Mechanical Engineers, B31.8S ‘Supplement to

B31.8 on Managing System Integrity of Gas Pipelines, 2001.

7.

BIANCHETTI, R.L, et al, Peabody’s Control of Pipeline Corrosion by A.W. Peabody,

published by NACE Press, 2001.

8. ELIAS, V., USDOT Publication No. FHWA-NHI-00-044. ‘Corrosion Degradation of Soil

Reinforcements for Mechanically Stabilized Earth Walls and Reinforced Soil Slopes’,

2000.

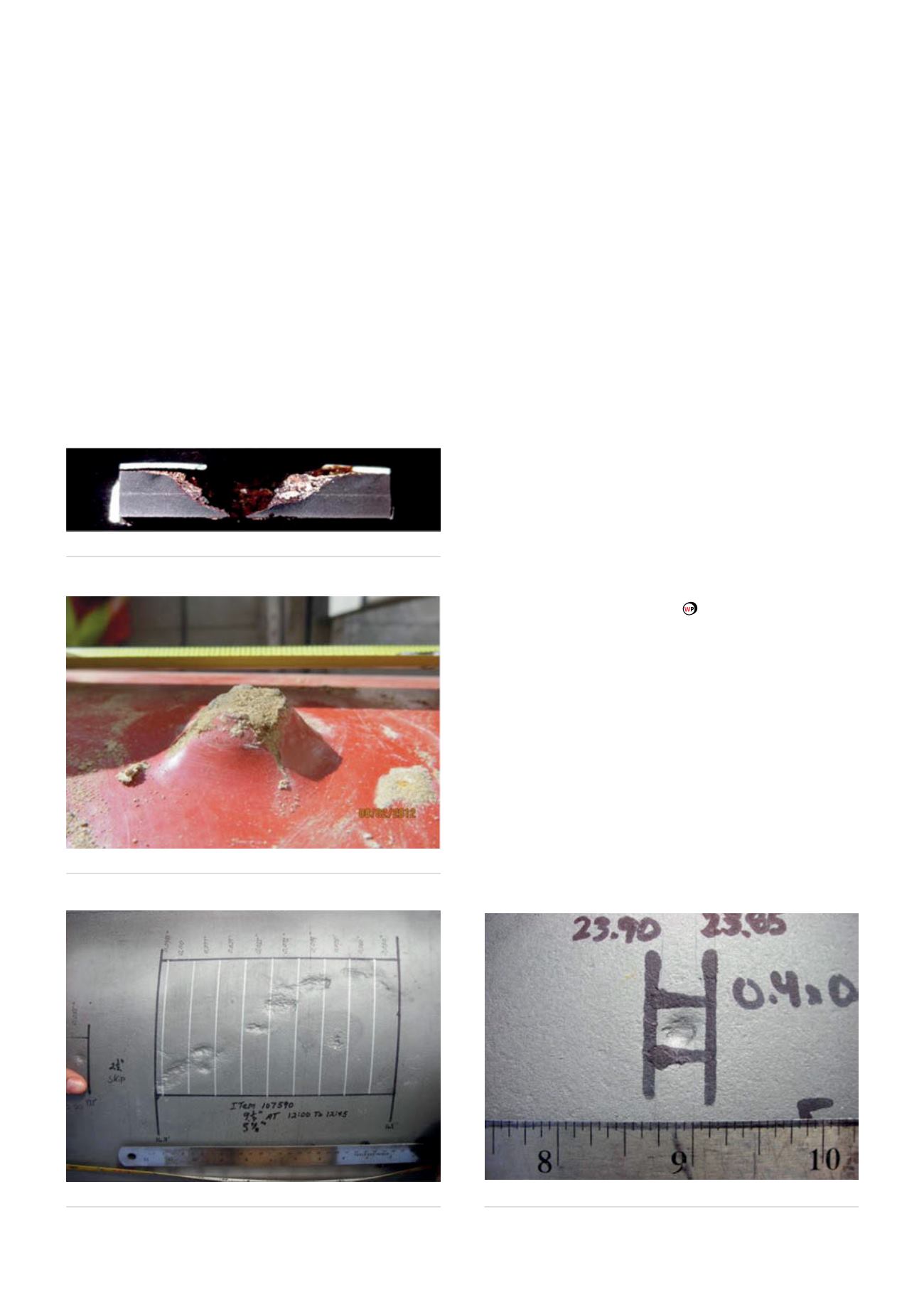

Figure 4.

D-C stray current FBE undercut.

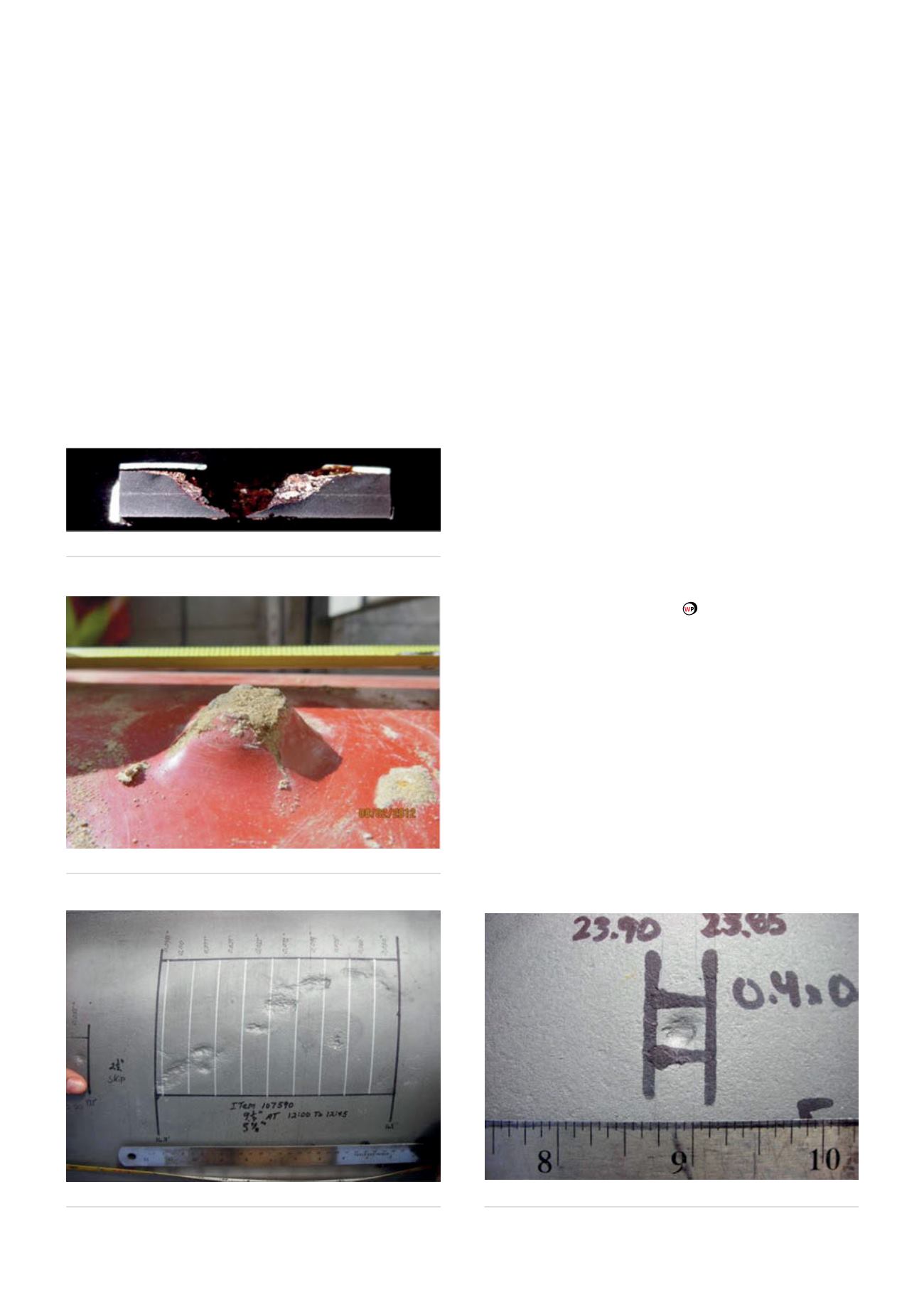

Figure 5.

Non D-C stray current coating ‘lift-off’.

Figure 6.

Localised pitting corrosion.

Figure 7.

Localised pitting corrosion.

118

World Pipelines

/

AUGUST 2015