The quality of the weld between

two sections of pipe is critical to

ensuring the integrity of a pipeline. For

years, radiography was the method of

choice to verify the integrity of these

welds. More recently, the development

of automated ultrasonic testing (AUT)

techniques, including phased array and

time-of-flight diffraction (TOFD), has

significantly improved the efficiency of

ultrasonic inspection, advantageously

replacing RT in many applications.

Unfortunately, when applied to

CRA-clad welds, AUT has presented

certain limitations and more advanced

tools had to be developed.

Advanced automated

ultrasonic testing

An automated ultrasonic in-situ system

consists of a pair of phased array

probes that generate multiple beams

to cover specific zones of the weld

(zone discrimination technique), and

a pair of TOFD probes for volumetric

inspection. These are mounted on a

fully automated scanner. The weld is

inspected in its entirety in a single pass,

and the results are immediately shown

on screen. Inspectors, benefitting from

easy-to-interpret strip chart imaging, are able perform a quick

assessment of the quality of the weld.

Phased array technology is based on the capacity to

electronically modify ultrasonic beams generated by probes

that contain multiple small elements. When these elements

are excited using different time delays (focal laws), the beams

are steered at different angles and focused at specific depths.

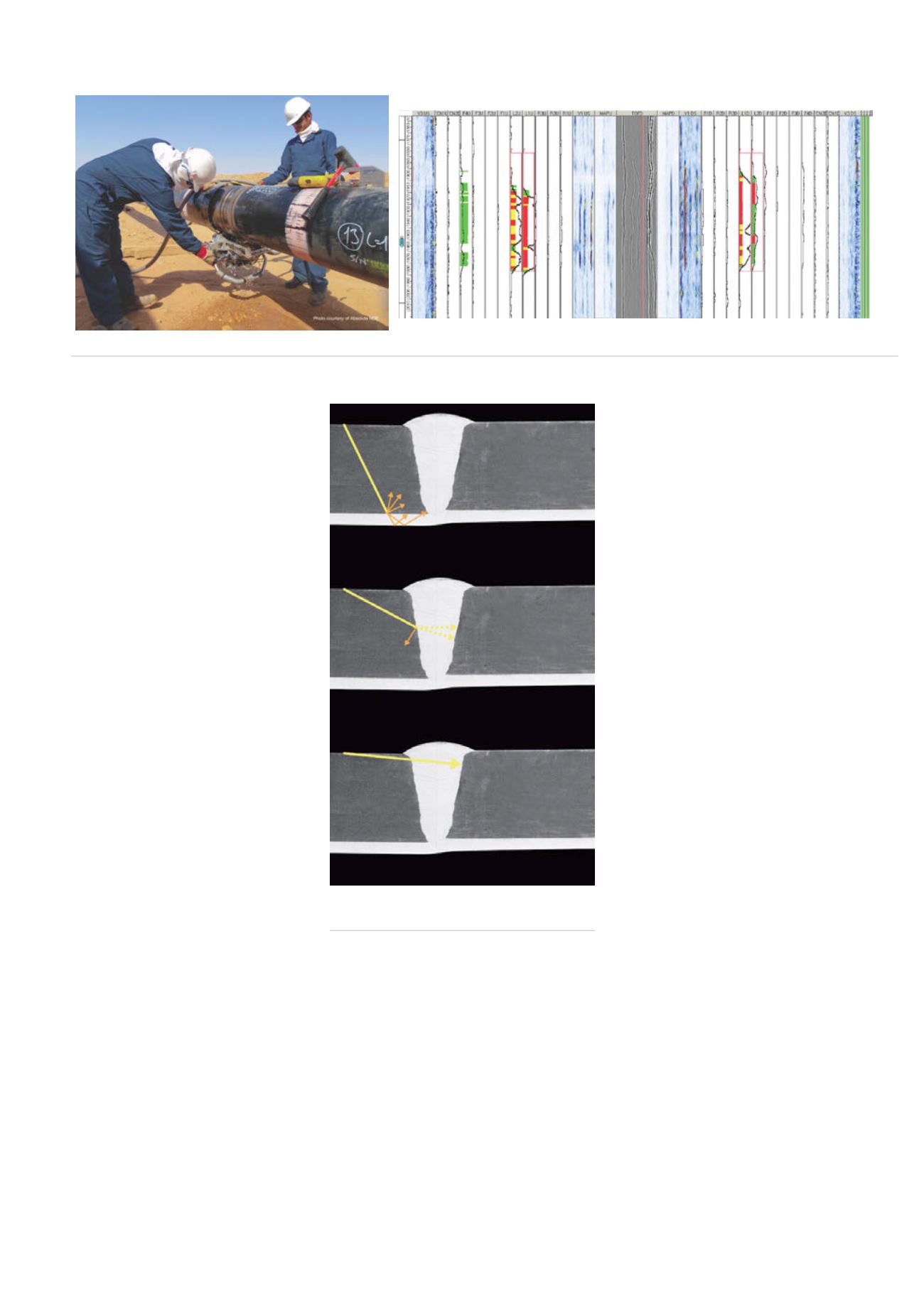

Time-of-flight diffraction (TOFD) is an ultrasonic technique

that relies on the property of cracks and similar defects to

diffract energy when impinged by ultrasonic beams. Two

ultrasonic transducers, one transmitter and one receiver,

work in tandem to inspect the volume of a weld. When a

crack is present in the weld, its tips diffract waves back to

the receiver (Figure 3), and the depth

of the crack is defined using simple

trigonometry. The use of the B scan

facilitates interpretation of the signal

and increases the probability of flaw

detection.

Advantages over RT

While radiography (RT) is the most

commonly used technology in

the industry, it has major safety,

environmental, and licensing

limitations, plus limited capability

for detecting critical planar defects.

In contrast, AUT offers a higher

probability of detection of critical

planar defects, plus the capability to

accurately locate them. In particular,

the capability of AUT to vertically

size defects permits the use of

more accurate fracture mechanics

calculations, relaxing the acceptance

criteria for critical flaw length. This

results in less frequent need for weld

repair, representing significant savings

for pipeline contractors. In addition,

AUT does not require the use of

chemicals or radiation protection

procedures. AUT inspection is also

faster than radiography. Furthermore,

AUT is now recognised by many international standards as a

replacement for RT.

CRA-clad pipeline

CRAs are very effective, but they are costly. To limit the

cost of pipeline construction, only the inside wall of the

pipes are lined with a layer of CRA material with enhanced

properties. Depending on the environmental conditions,

various combinations of materials and thicknesses can be

used; for example, a layer of Inconel clad on a carbon steel

pipe. The CRA can be bonded to the inside of the pipe using a

metallurgical (clad) or a mechanical (lined) process. The same

CRA material is also used in the weld that joins pipes together

Figure 1.

Olympus PipeWIZARD system in operation (left); Olympus PipeWIZARD strip chart imaging showing indications (right).

Figure 2.

Effects of the CRA-clad layer and

weld on ultrasnic shear waves.

122

World Pipelines

/

AUGUST 2015