Figures 1 - 7 show corrosion attributable to several of these

corrosion mechanisms, with their characteristic morphologies.

These factors are typically localised rather than systemic. Where

the root cause analysis identifies additional factors as contributors

to metal loss, appropriate solutions should be developed by

qualified individuals. In general, the application of cathodic

protection (CP) is the most effective corrosion control method

to address metallic surfaces that are not isolated from the soil

environment by protective coatings (i.e., at coating flaws). CP

alone may not be the most practical approach to all factors or

combinations of factors. For example, stray current influences,

whether static or dynamic, are often best controlled at the source

rather than attempting to overpower them with CP.

The recognised standard of the corrosion control industry is

that effective control, and specifically effective CP, is achieved

when the corrosion rate is reduced to less than 0.025 mm/yr

(1 mil/yr).

Some of the factors listed above may require increased

protective current densities to achieve the recognised CP criteria.

Others may require modifications to the criteria – for example,

the International Standards Organisation (ISO) has established a

polarised potential criterion of -950 mV (additional 100 mV of

polarisation) in the presence of active MIC to achieve a reduction

in the corrosion rate to less than 1 mil/yr.

Electrical shielding encompasses conditions that do not

actually affect the corrosion rates of the general soil environment;

rather, they create a separate environment for portions of the

pipe surface and prevent the distribution of cathodic protection

current into those areas. The most common conditions that cause

electrical shielding include disbonded coating, other dielectric

barriers around the pipe, non-conductive rock formations or

geological features, and intervening metallic structures such as

parallel pipelines or shorted casings.

Effect of CP

The following citations are not intended to summarise or critique

the related CP criteria. Rather, they are intended to demonstrate

that the definition of ‘effective cathodic protection’ as a reduction

of the corrosion rate to less than 1 mil/yr is fundamental to

the historical research and generally accepted throughout the

corrosion control industry.

In the Cathodic Protection 2 Education Course, NACE

International has recognised the generally accepted industry

definition of effective corrosion control: under the ‘Basis of

RP0169 Criteria’ section (now SP0169), regarding the -850 mVCSE

polarisation criterion, the text states “it is generally agreed that

this criterion reduces corrosion to approximately 1 mil/yr.”

NACE International’s Standard Practice, SP0169-2013, ‘Control

of External Corrosion on Underground or Submerged Metallic

Piping Systems’ states, “a commonly used benchmark for effective

external corrosion control is a reduction in the corrosion rate to

0.025 mm/yr (1 mil/yr) or less.”

850 mV negative polarised pipe-to-soil

potential

In order to provide a consistent basis for comparison of

experimental results, the classic research adopted the common

definition of effective CP as the reduction of corrosion rates to

less than 1 mil/yr (0.025 mm/yr). Some of the more significant

examples follow:

)

)

Schwerdtfeger & McDorman, 1952

1

: “the corrosion rate had

reached a negligible value…this value is associated with

corrosion rates that are less than 1 mil/yr.”

)

)

Thompson and Barlo

2

: “corrosion is assumed to be mitigated

when the corrosion rate falls below 1 mil/yr.”

Table 1. Table SP-B1 (adapted from ASME B31.8S)

6

Corrosion rate (mil/yr)

Soil resistivity (OHM-CM)

3

>15 000 + no active corrosion

6

1000 - 15 000 and/or active corrosion

12

<1000 (worst case)

Table 2. Table 11.6 rough current requirements for CP of steel

(excerpted from Peabody, p. 499)

7

Conditions for bare steel

Current required (mA/m

2

)

In moving seawater

100 - 160

In quiet seawater

55 - 85

In earth

10 - 30

Figure 1.

General corrosion.

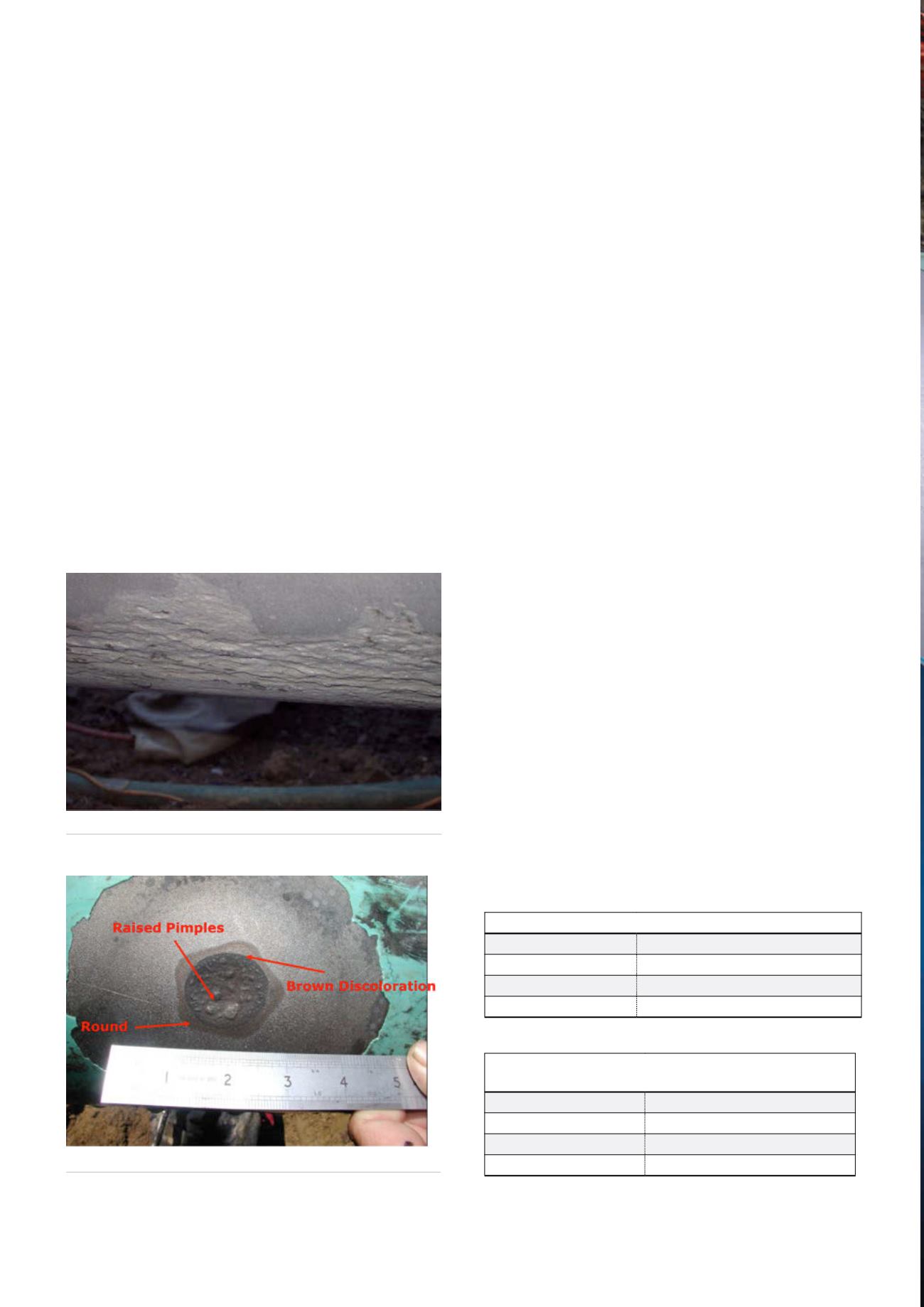

Figure 2.

A-C corrosion.

114

World Pipelines

/

AUGUST 2015