None of this, however, absolves operators from

their future responsibility. IVP is on its way. So while the

expectation is clear, the possibility still exists that the

proposed rule could catch operators off-guard.

The best bet to avoid a sneak attack is through advanced

planning and preparation. That is why even though the

regulation is not a reality yet, many operators are looking to

get a head start.

All pipe joints are not created equal

Among the requirements of PHMSA’s ADB-2012-06 is the

validation of material records. In many cases, however, those

records are either insufficient, have been lost over time, or

were never kept in the first place.

So this leaves operators asking two questions: Is it possible

for me to satisfy the IVP requirements without incurring all of

the associated costs of extensive excavations and laboratory

testing? And, if so, can I accomplish the same results through

non-destructive methods alone?

The answer to both questions is yes. “The solution

is twofold,” says Chuck Harris, Manager, Strategic

Commercialisation at T.D. Williamson (TDW). “First, inline

inspection (ILI) with a comprehensive technology like the

multiple dataset platform, (MDS) to classify pipe joints by

their characteristics. Second, following the integrity report,

verification of materials through the positive materials

identification (PMI) process.”

As the market’s most comprehensive inspection platform,

MDS is comprised of a robust combination of complementary

technologies. When specifically applied to IVP requirements,

MDS provides the following:

)

)

Low field magnetic flux leakage (LFM), the foundational

dataset for grouping pipe joints. LFM reveals mechanical

characteristics related to manufacturing and milling

through background gauss levels and microstructure

changes.

)

)

Deformation or geometry inspection (DEF), which

identifies bore and long seam trim characteristics.

)

)

High field axial magnetic flux leakage (MFL), used to

confirm magnetic properties.

)

)

SpirALL® MFL, which distinguishes differences in long seam

characteristics.

)

)

Radial/IDOD (internal/external discrimination) used to

identify additional characteristics related to the internal

pipe wall.

In a certain sense, MDS allows operators to go back

in time: The platform can identify carbon steel pipe joint

characteristics based on the manufacturing or milling process,

information that can unlock the mystery of what a large

section or even an entire pipeline is made of.

As Harris explains, pipe joints with similar manufacturing

or milling should share certain similar material properties.

MDS can be used to identify common characteristics of a

representative sample of pipe joints, producing information

that can be validated by the PMI process and then applied

more broadly.

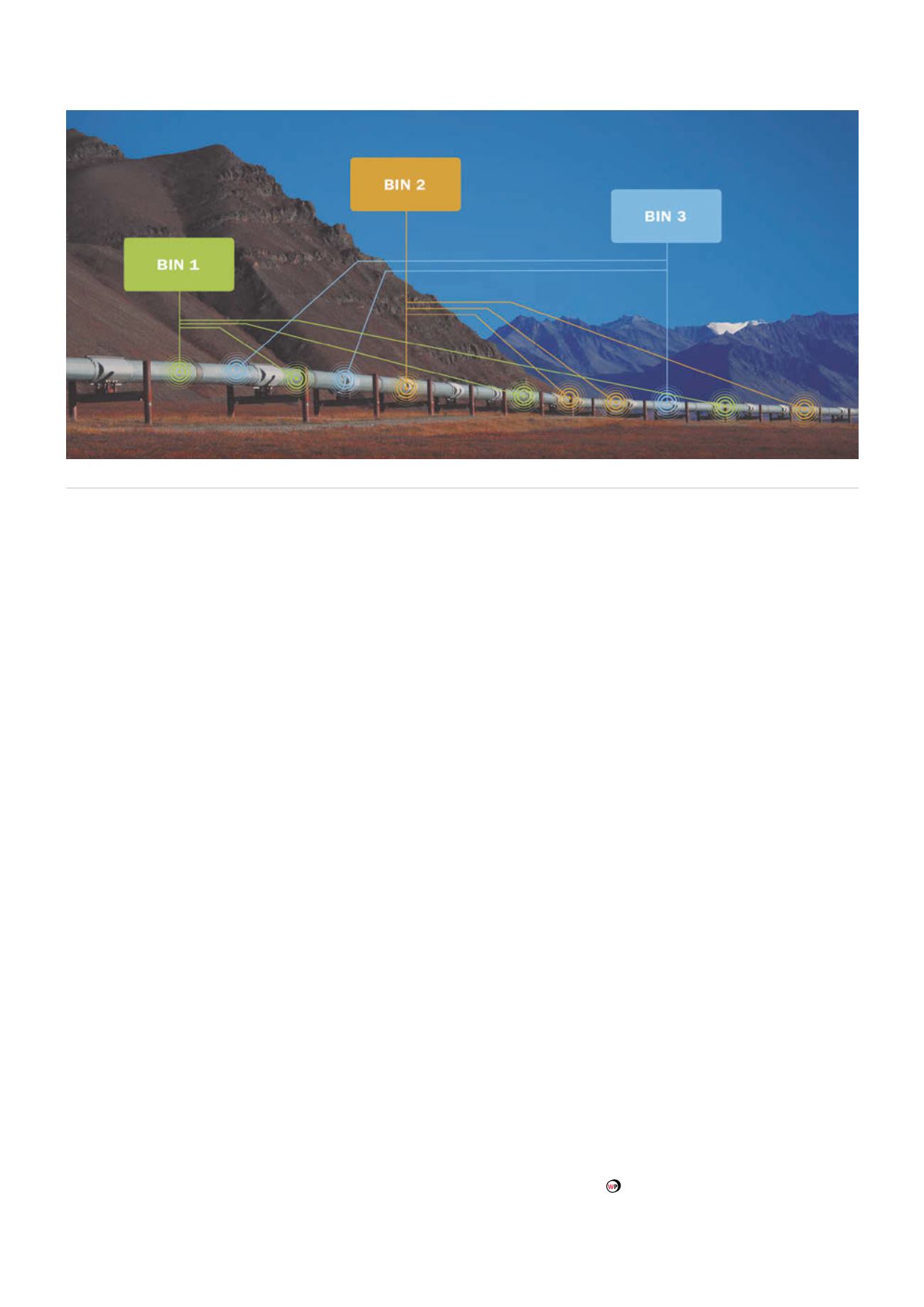

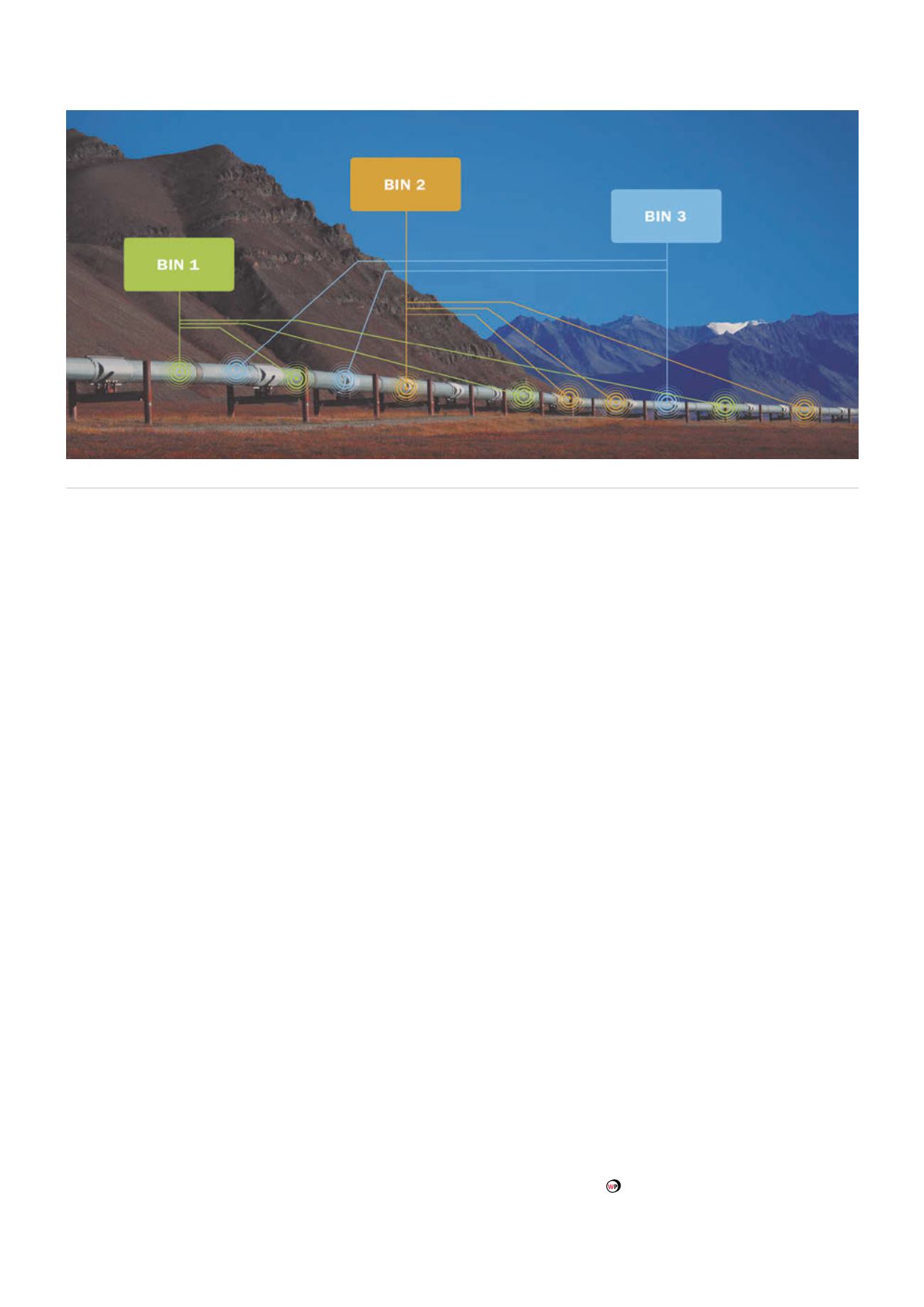

“Let’s say MDS has allowed you to identify 1000 similar

joints that are grouped together in what we’ll call a bin,” Harris

says. “It would be possible, and it’s our objective, to allow a

subset of those 1000 joints to be validated by PMI and apply

the findings to all 1000.

“This could then be used as the basis for identifying

material characteristics for all of the joints in an entire bin.

In other words, by validating a subset of joints, we could

determine the characteristics of all of them,” Harris adds.

The result is the foundation for establishing complete

material records where none exist. And not only will that fulfil

future PHMSA rules, it can keep operators from looking over

their shoulders for surprises – and maybe stave off a few grey

hairs in the process.

Figure 1.

Representation of pipe joints with similar characteristics.

110

World Pipelines

/

AUGUST 2015