Chennai at the eastern coast of India.

The total investment for this strategic

project has been in the magnitude of

€100 million.

The NTECL project

At NTECL, domestic and imported

coal for the power plant is first

received at the Port of Ennore and

unloaded by means of gantry-type

grab unloaders. It is then conveyed to

the plant, which is 4.5 km away from

the port area.

In order to minimise the mooring

time of incoming vessels with a

capacity of up to capesize dimensions

and to match the power plant’s

demand of 13 400 tpd of coal, a

conveying capacity of 4000 tph was

requested by the customer.

The local environment in this region

is characterised by creeks, valuable

fishing habitants and backwaters, as

well as by an important railway

connection. Therefore, the protection of

the environment and a small footprint of

the conveying systemwere always in

the focus of all consideration of the best

means of trandsporting the coal from the

port to the crusher house of the new

power plant.

FLSmidth was the frontrunner in this

project, standing out against

international competition from

well‑known suppliers of both

conventional troughed belt conveyors

and pipe conveyors. FLSmidth’s

expertise and track record of more than

350 installed KOCH Pipe Conveyors

®

worldwide, including supply and

installation of one of the longest pipe

conveyors in the world in Lima, Peru,

combined with its excellent customer

service, contributed to NTECL’s decision

to award the order to FLSmidth.

Through FLSmidth’s innovative

thinking and close cooperation with the

client’s experts, challenges that had

been considered as technically

impossible only a couple of years ago

became reality when FLSmidth’s

KOCH Pipe Conveyor concept was

adapted to this demanding project. Due

to its small footprint, low

noise‑emission level and nearly

dust-free transport of the coal, this

system allows the lowest possible

environmental impact.

Engineering excellence

For the first time in history, a pipe

conveyor at a length of 4.5 km and a

belt speed of 6.2 m/sec. was designed

with a capacity of 4000 tph and a

diameter of 650 mm, which makes it the

world’s largest pipe conveyor. This new

pipe conveyor design sets a milestone

for the Indian power industry’s need

for environmentally friendly

infrastructure for its future

high‑efficiency power plants.

Every single component of the pipe

conveyor was critically examined based

on the specific application and was

sourced globally from market-leading

suppliers to ensure a reliable system at

the highest level of personnel and

operational safety.

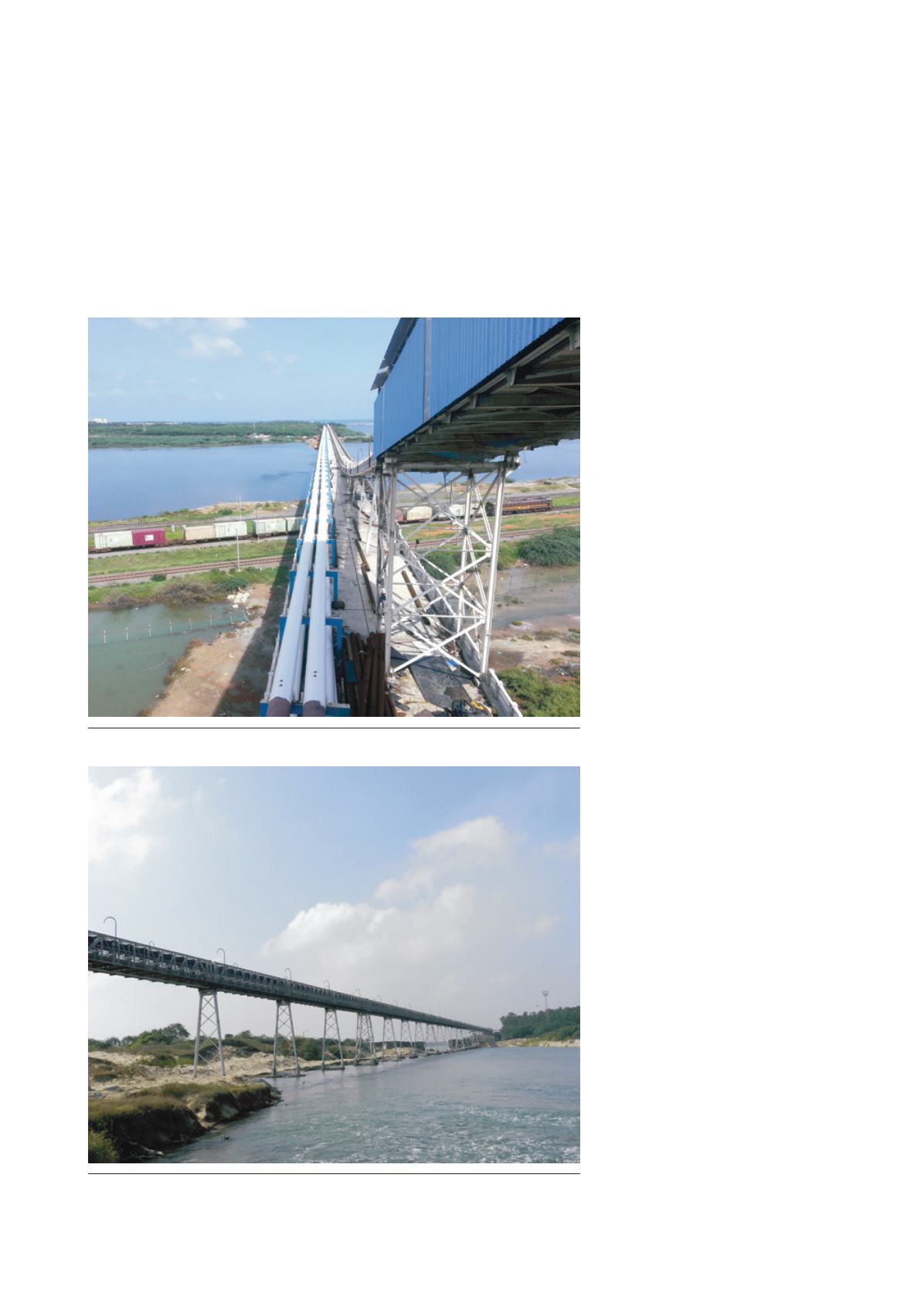

Pipe conveyor safely crossing over the railway tracks.

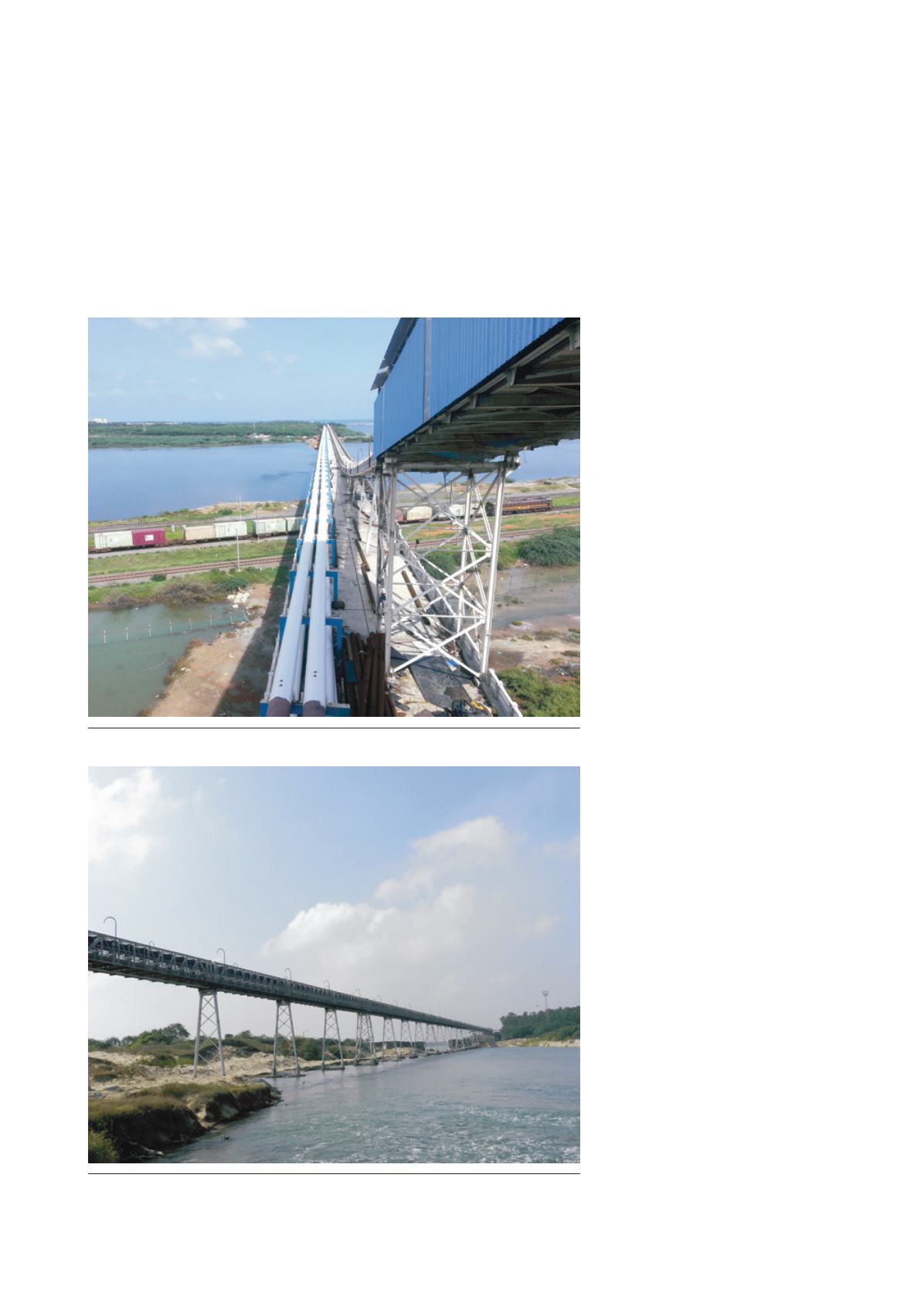

Waterbody unaffected, while the pipe conveyor passes over.

36

|

World Coal

|

July 2015