the client specifications due to the high

belt speed of 6.5 m/sec.

Manufacturing of all components

was accomplished by local suppliers in

South Africa and civil construction

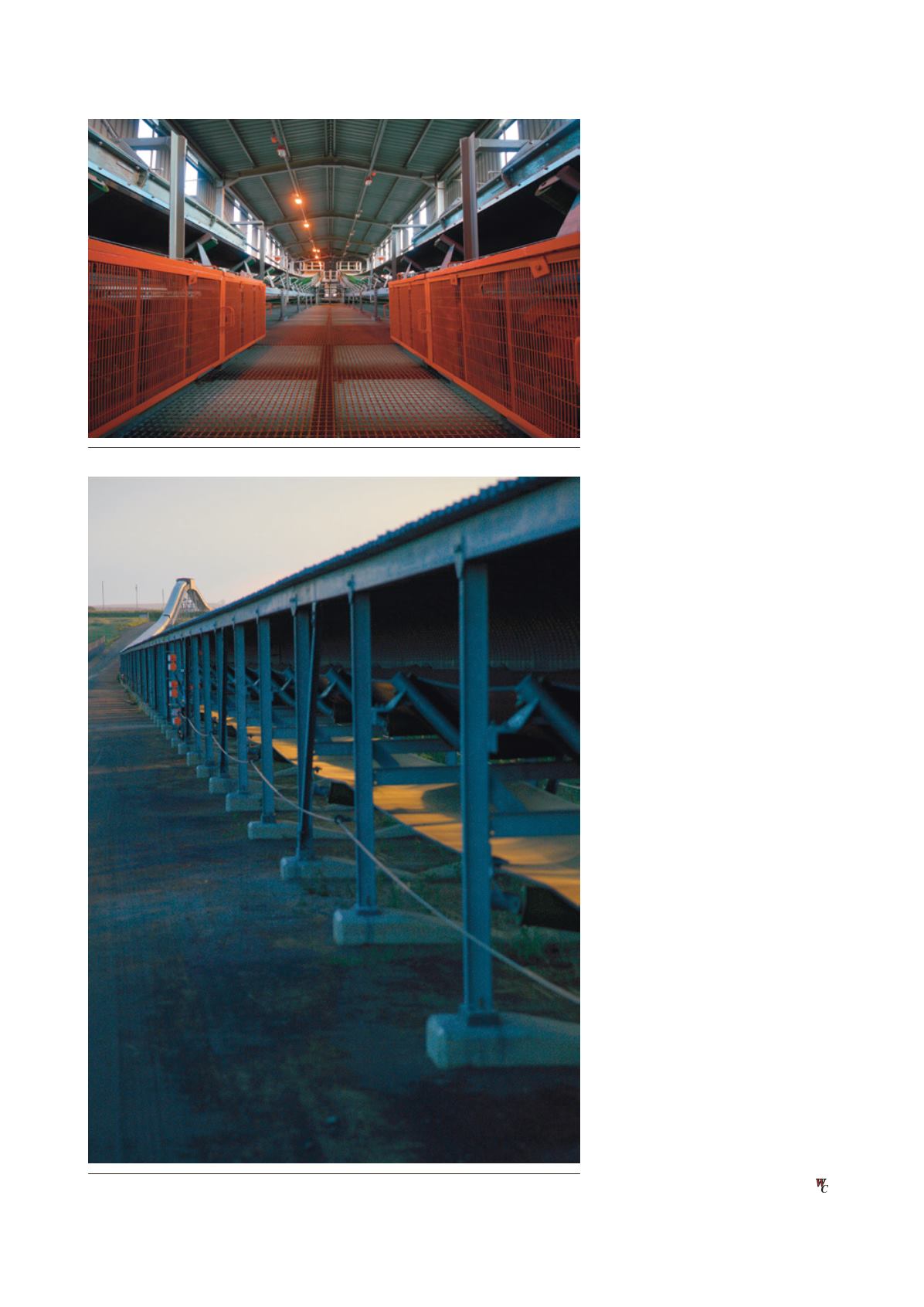

began in early 2013. The overland

conveyor was produced in a

lightweight H-frame modular design

derived from the Thubelisha project,

while the civil base design consists of

two mini-piles with an extremely

lightweight precast sleeper weighing

in the region of 80 kg versus the 630 kg

of gravity sleepers. In combination,

these elements represent a design

innovation that optimises the timing of

the installation of the overland

conveyor.

In terms of environmental impact,

spillage was a major concern to the

client. The Sandvik Mining Systems

team addressed this by providing all

the transfer towers with bunded areas

that have a specific drying sump to

contain spillage. Specific attention in

this regard was given to the overland

conveyor, which crosses five

environmentally sensitive wetlands

and spans a river. At the river crossing,

the conveyor is elevated and sealed off

for a length of 800 m.

The design team also had to take

into account the noise generated by the

overland conveyor. A study to

determine the main causes of noise

generation associated with this

structure led to the use of HDPE rolls,

instead of steel idler rolls, to muffle the

noise as coal is conveyed past

farmhouses and informal settlements.

A decrease in the sound power level of

up to 4 dB can be expected.

Cold commissioning is scheduled

towards the end of 2015 and the date

of hot commissioning will be

determined by the coal supply from

the client.

Conclusion

These and other similar projects across

Africa provide a clear indication that

Sandvik Minings’ capabilities in

long‑distance curved and complex

overland conveyors are being

recognised in the marketplace. Its

in-house solutions and turnkey project

solutions are attracting increasing

attention throughout the continent.

Figure 3. Curved overland conveyor at Thubelisha.

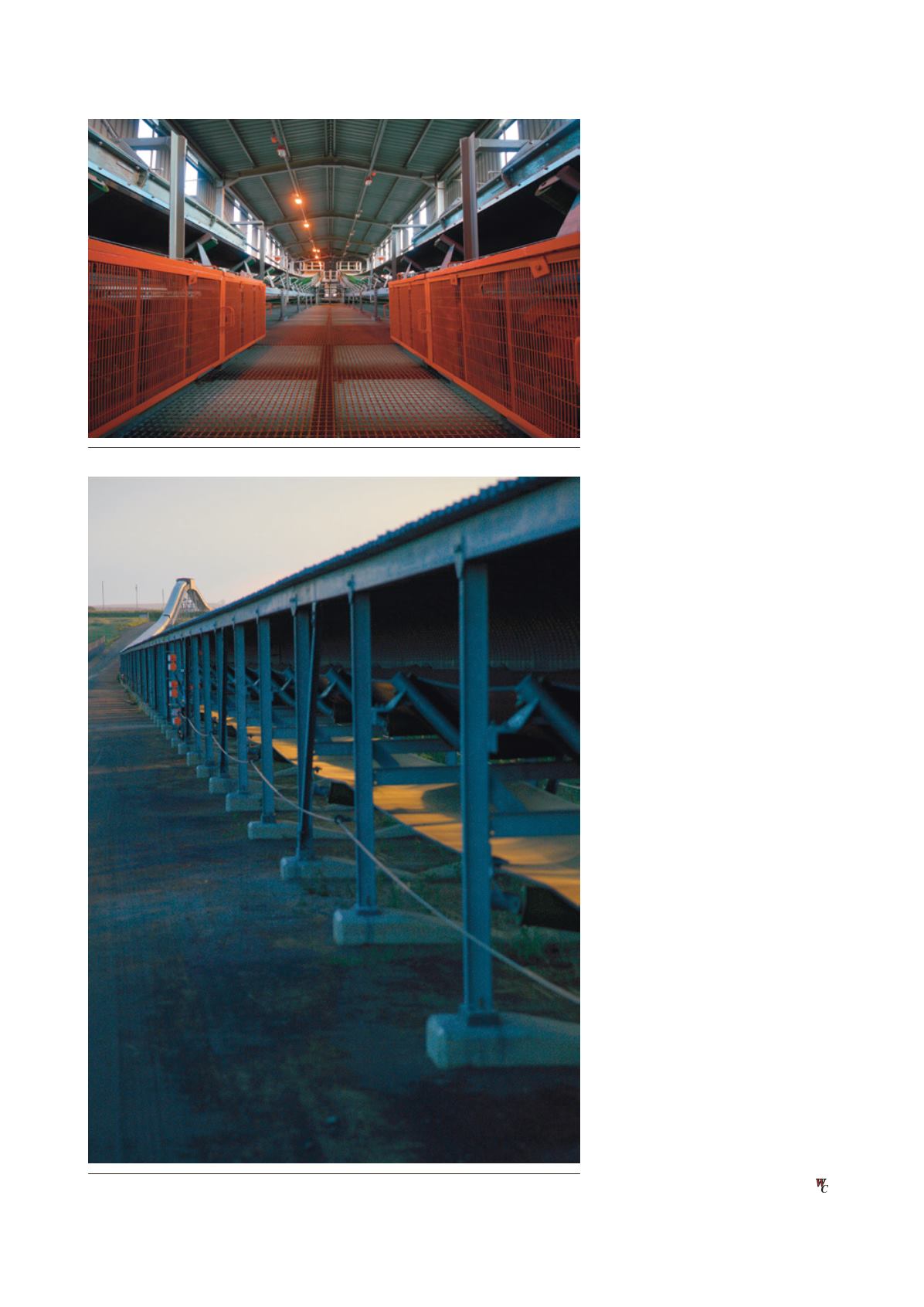

Figure 2. 15 000 t surface bunker with tripper conveyors and trippers.

30

|

World Coal

|

July 2015