and evaluated using 3 DEM™ chute

design software. During the final

review and approval of the chute

design, a problem was discovered due

to a frequently occurring operator

error. During stack out at 3000 tph, the

operator can cause the system to

reclaim at the same time – going the

wrong way on the belt. Thus this

causes up to 1400 tph to go the wrong

way on the yard belt. The only way to

make it work would be to use a split

chute design with a diverter gate and

actuator. The coal yard supervisor was

reluctant to incorporate a diverter gate

into the new design because of the

problem of the gate freezing up during

winter operations.

How do you change the direction of

the coal stream inside a transfer chute

without using a diverter gate? The

design engineers came up with a

solution that used a movable deflector

hood in the head discharge area to

divert the coal stream into one of two

outlet chutes. This design eliminated all

of the buildup and freezing issues that

occur when using an in line, swing

blade diverter gate (Figure 6 and 7).

A new transfer chute was modelled

and designed to allow the coal to be

loaded onto the receiving belt, moving

in the same direction, speed and in the

centre. The new design also eliminated

corner buildup and reduced wear due

to impact and misdirection. The

adjustable upper deflection hood was

power actuated to prevent a chute

overload when the upset condition (i.e.

reclaiming while stacking out) was

occurring. The hood was automatically

positioned in the head chute to direct

the coal during either stack out or

reclaim. This prevents a chute

overload during the upset condition.

Three different types of internal

wear liners were used in different

areas of the transfer chute, depending

on what type of abrasion was

occurring. A chromium carbide

overlay plate was used in the

high‑velocity flow area and either

UHMW or a hardened stainless steel

liner was used in the splash and

dribble chute areas.

The new transfer chute now

operates without buildup and the coal

flow is centre loaded onto the 60 in.

receiving belt at the same speed and

direction. This reduces wear and belt

mistracking, as well as fugitive dusting

and spillage clean-up. There is no

longer a need for chute vibrators and

the plant has still not re-installed the

heaters.

Conclusion

To create an efficient, safe and reliable

transfer point, there are many essential

products that eliminate spillage, control

dust, support the belt and make the

system more productive and safe.

Several products have been discussed

in this article; but not all. Effective belt

cleaning systems, belt tracking devices,

dust fogging systems and more are

often necessary to reduce spillage and

dusting, as well as operate in

compliance with all of the current

regulations that are now in place.

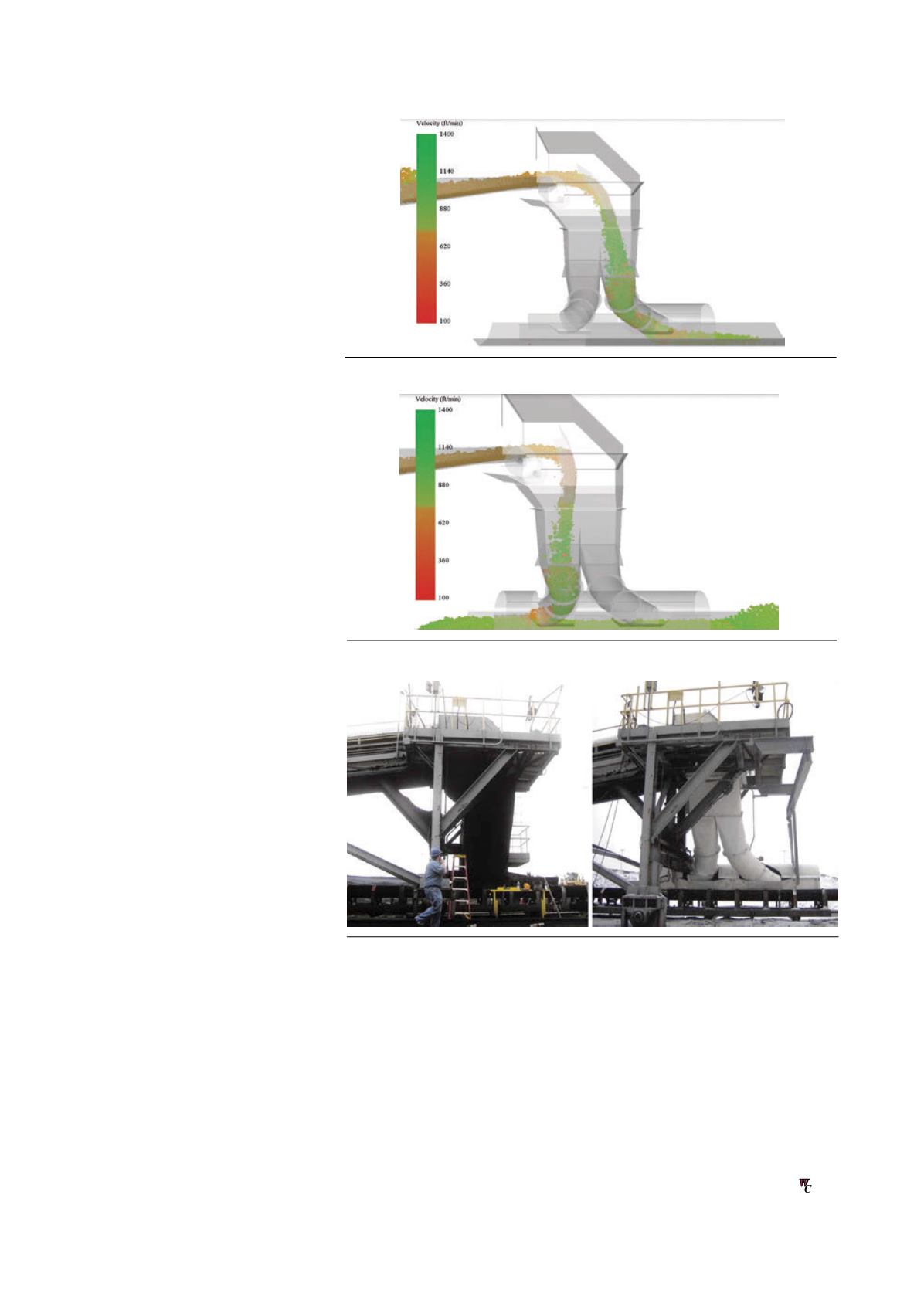

Figure 6. Hood in reclaim mode.

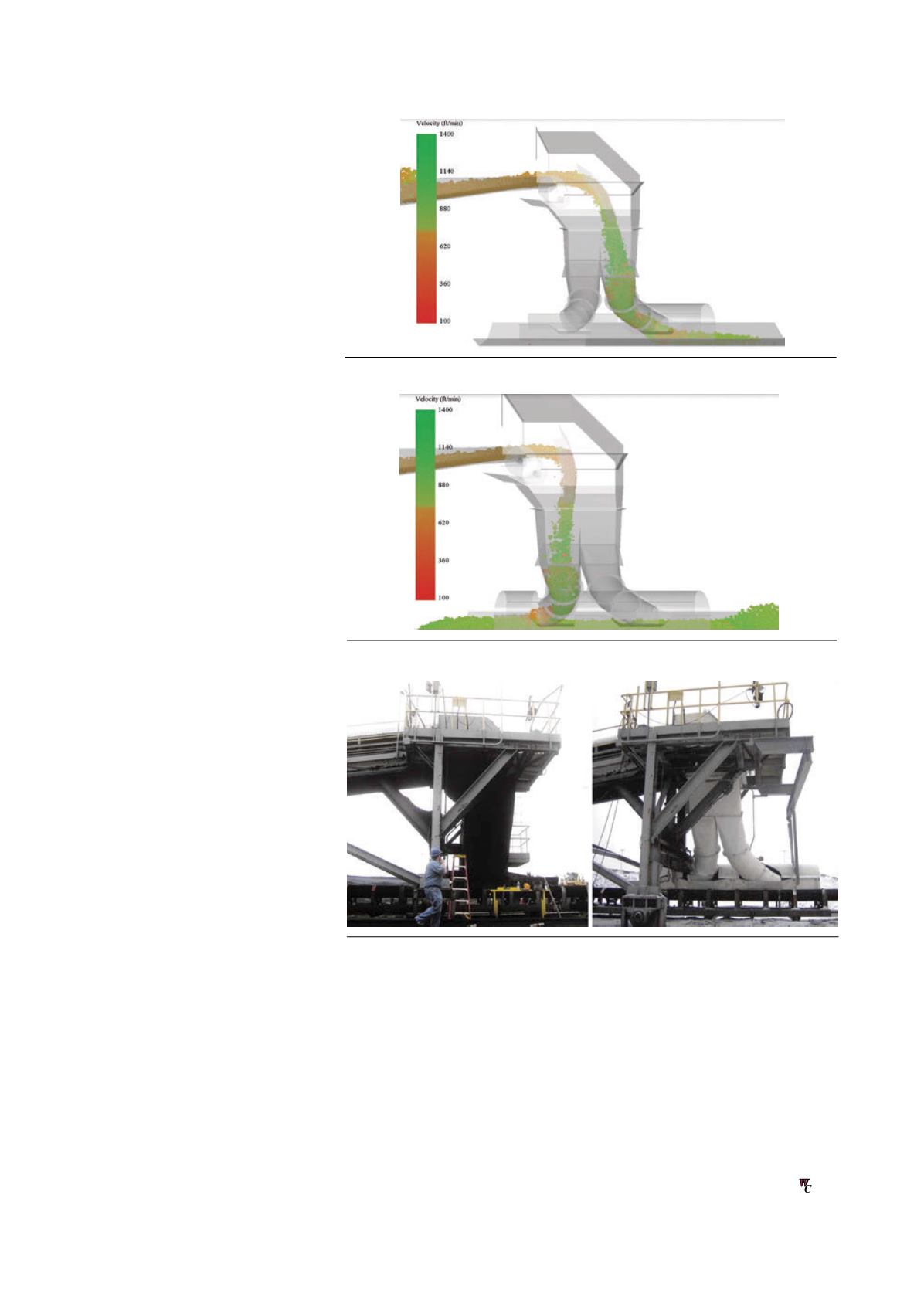

Figure 7. Hood in stack out mode.

Figure 8. Before (left) and after (right) installation of the new transfer chute with

movable deflector gate in the head discharge area and two outlet chutes.

August 2015

|

World Coal

|

41