automated overfill prevention system (AOPS) that

automatically stops any filling above a certain level. It should

be noted that an AOPS is a safety instrumented system (SIS)

in the IEC 61511.

Such an AOPS is a system that must be independent of

the basic process control system (BPCS), which in this case is

the normal operations control system and is in addition to

the BPCS. The AOPS can be combined with any of the tank

Categories 1 - 3. However, in most cases, it would make sense

to combine it with either a Category 2 or 3 overfill prevention

system. Sometimes AOPS is also called ‘Category 4’.

Although currently AOPS are not yet frequently found in

current tank filling operations, they will eventually become an

important tool in the toolbox of overfill prevention. In order

to fulfil the API 2350 such automatic overfill prevention

systems in new facilities must be compliant with IEC 61511.

In the world of safety instrumented systems, IEC 61511 is

one of the specific industry standards that have been

developed which apply to electrical and/or electronic and/

or programmable electronic devices to control dangerous

processes. These standards cover possible hazards caused by

failure of the safety functions by the safety related systems.

These standards represent the best possible methodologies to

ensure that safety systems operate as intended. These safety

instrumented systems are applied to railway signaling systems,

remote monitoring and operation of process plants,

emergency shutdown systems, burner management systems

and many more. By their very design, when combined with

normal operating systems and basic process control systems,

they can achieve a level or risk reduction that cannot be

achieved without them.

So why the hesitancy to use them?

One key reason is that if they are not properly designed a

pipeline can be damaged by closing off the product flow too

quickly. In order to do avoid this, the valve closure time must

be sufficient so that there is no possibility of a line rupture. A

significant amount of data collection and engineering is

required to prevent the risk of a pipeline rupture. On receipts

from tank ships, the temporary hoses that connect ship to

terminal can disengage or rupture due to hydraulic transients,

and a spill in the water is generally more serious than a spill in

the terminal. Care must be exercised when applying AOPS to

any marine or pipeline operation.

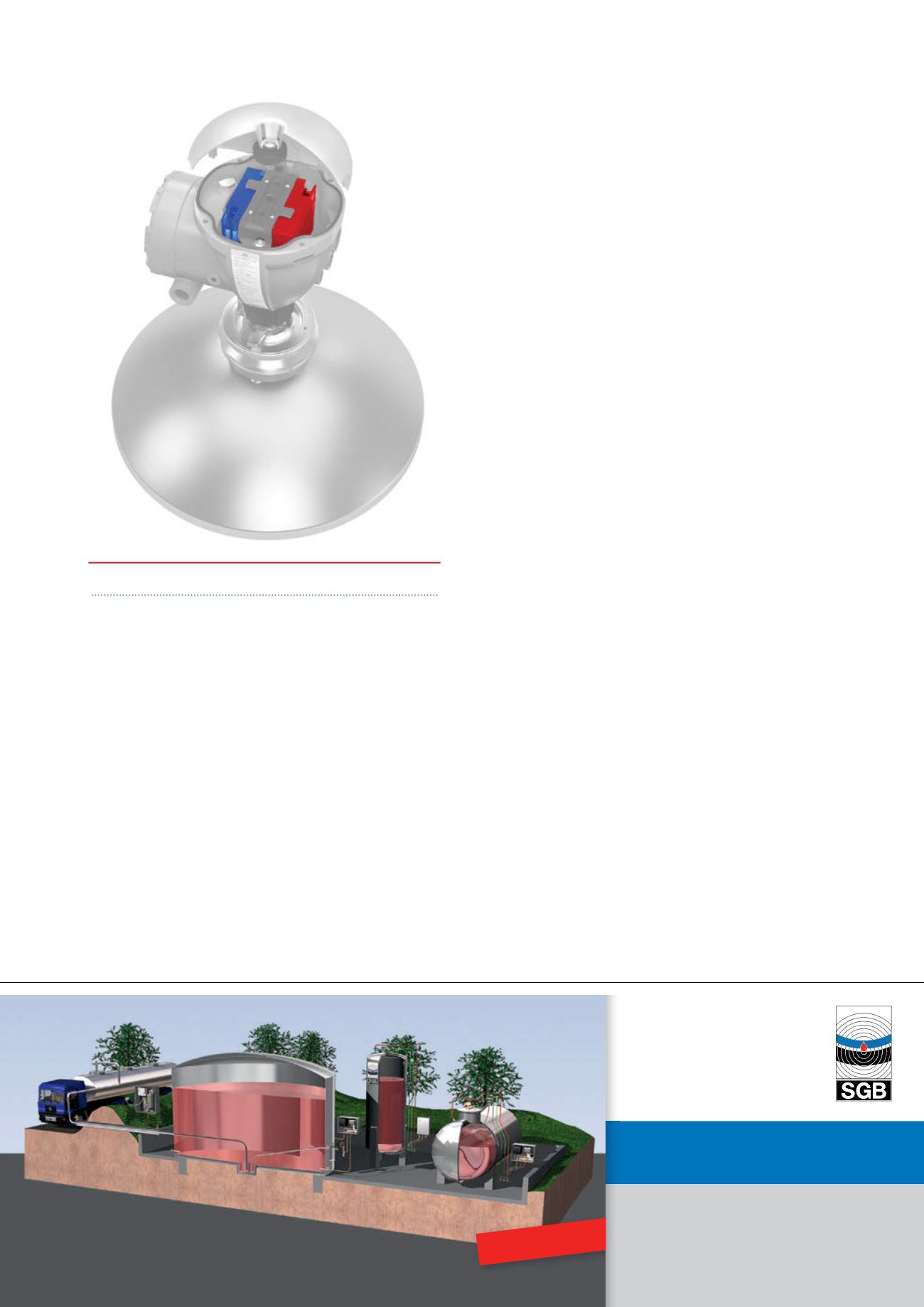

An example of an AOPS configuration is seen in Figure 2

with radar level gauges connected to emergency shutdown

devices and logic solvers.

Why use API 2350 and not

some other safety standard?

The advantage of API 2350 is that it is a modern safety

standard for a specific use case (overfill prevention) in a

specific application (non-pressurised aboveground large

petroleum storage tanks). It was created by the industry for

the industry. A wide spectrum of industry representatives

participated in its creation: tank owners and operators,

transporters, manufacturers, and safety experts, just to

mention a few. It is a compilation of the minimum

requirements required to comply with modern best practices

in this specific application. Obviously the main purpose is

to prevent overfills, but another common result of applying

Figure 4.

Two radar gaugings in one housing.

LEAK PREVENTION TECHNOLOGY

For a clean and protected environment

Highest protection and safety for

• Refineries

• Tank farms

• Chemical plants

• Filling stations

SGB GmbH

Hofstr. 10

57076 Siegen

Germany

phone +49 271 48964-0

fax +49 271 48964-6

e-mail