HYDROCARBON

ENGINEERING

68

which effectively allow heat to flow from the

foundation upward creating a barrier to protect the

base and underlying soil from freezing. Electrical

heating cables are generally embedded within the tank

base foundation via conduits uniformly arranged across

the horizontal plane of the tank base. There are several

critical factors in the design of any cryogenic tank base

heating system which must be considered to ensure

safe and reliable operations. Eltherm has designed and

been involved in the successful installations of several

LNG tank foundation heating systems and below

outlines some of the critical steps in the design and

implementation phase of a tank heating system.

Heat tracing design

International standards provide guidelines and set

minimum requirements for the construction of onshore

LNG plant equipment, which include the tank base

structure and protection methods used to prevent

frost heave of the foundation.

2,3

A successful tank

foundation heat tracing system design must

incorporate and consider a number of key

requirements, including the characteristics of the tank

base, LNG tank structure as well as local atmospheric

and site conditions.

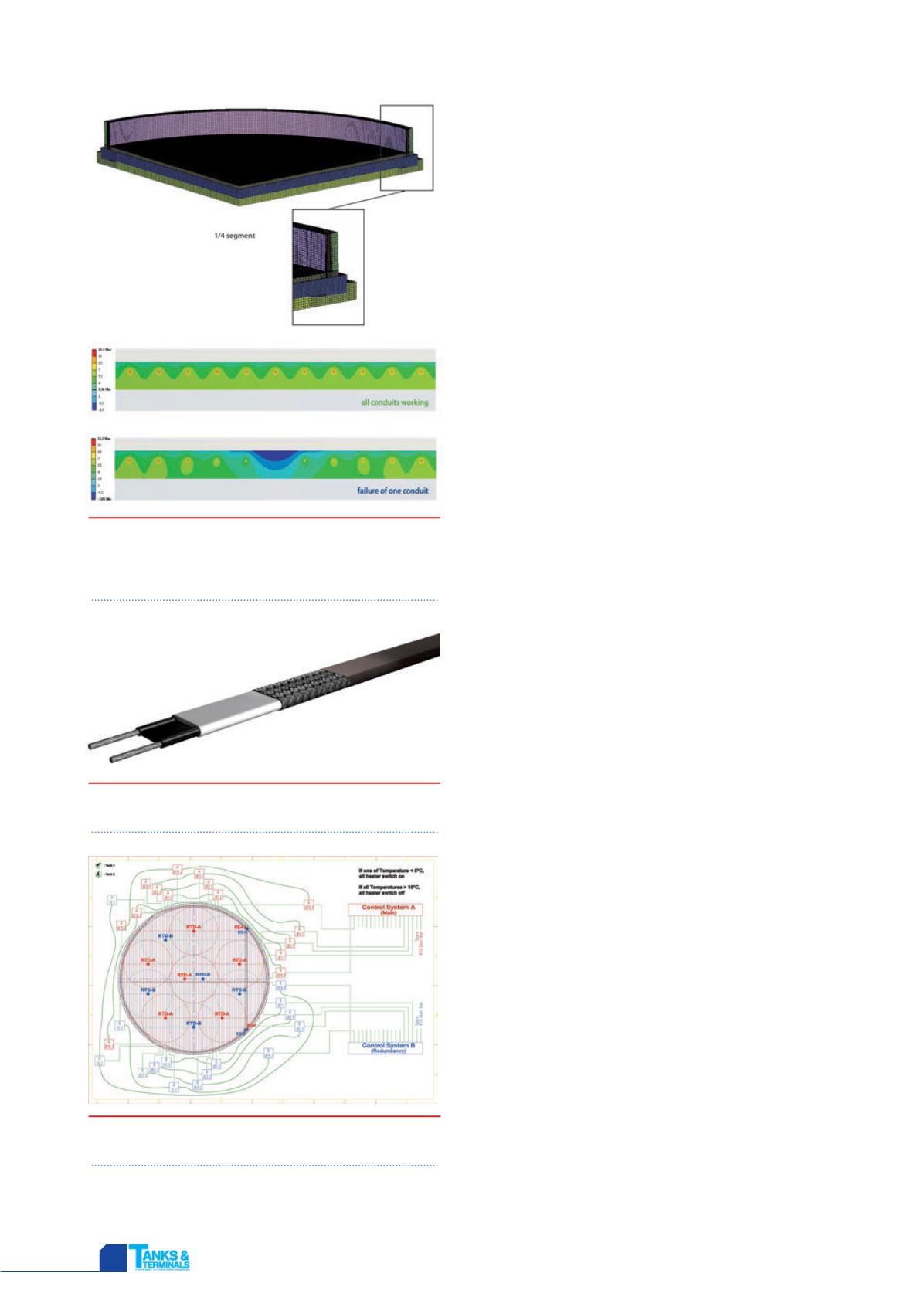

Tank base heating design begins with detailed

modelling of the heat flow and distribution of the

applied heat tracing within the concrete structure. To

accurately determine heat loss and optimum heat

transfer scenarios, eltherm design engineers utilise two

and three dimensional finite element analysis (FEA)

simulation software technology. These state of the art

tools provide the engineer with critical information,

including the visualisation of various heating system

construction scenarios and failure analysis simulation

of the system being designed.

Figure 1 provides simulation details of a recent

eltherm LNG tank base heating project. FEA modelling

allows the heat tracing engineer to simulate various

operating and failure mode conditions, and provides

crucial data for designing the optimum heat tracing

layout. LNG tank designs which incorporate a concrete

ring wall typically require a ring wall heating circuit to

counter convective heat losses from the outside of the

wall and the foundation edge of the structure.

An electrical tank foundation heating system

requires 100% redundancy, meaning the system must

continue to operate if the primary heating zone(s)

suffer from a partial or complete failure. The

monitoring and control system of tank base heating

systems must be carefully designed and integrated into

the overall scope to ensure that data is transmitted

rapidly to provide the operator with information

necessary to take corrective action as required.

Heating cable selection

The selection of a suitable heating cable or heat tracer

for the application is a critical step when designing a

heat tracing system. Heating cable manufacturers have

developed various technologies, ranging from series

resistance to parallel constant wattage and self

regulating heating cables, capable of providing a

Figure 1.

Simulated 3D temperature profile of

tank base foundation and 2D temperature profile

of slab heating in normal operating and failure

analysis mode.

Figure 2.

eltherm self regulating heating cable

ELSR.

Figure 3.

eltherm LNG tank foundation heating

basic system design.