HYDROCARBON

ENGINEERING

56

increasing terminal

efficiency, provide a

safer work

environment, and

reduce pollution.

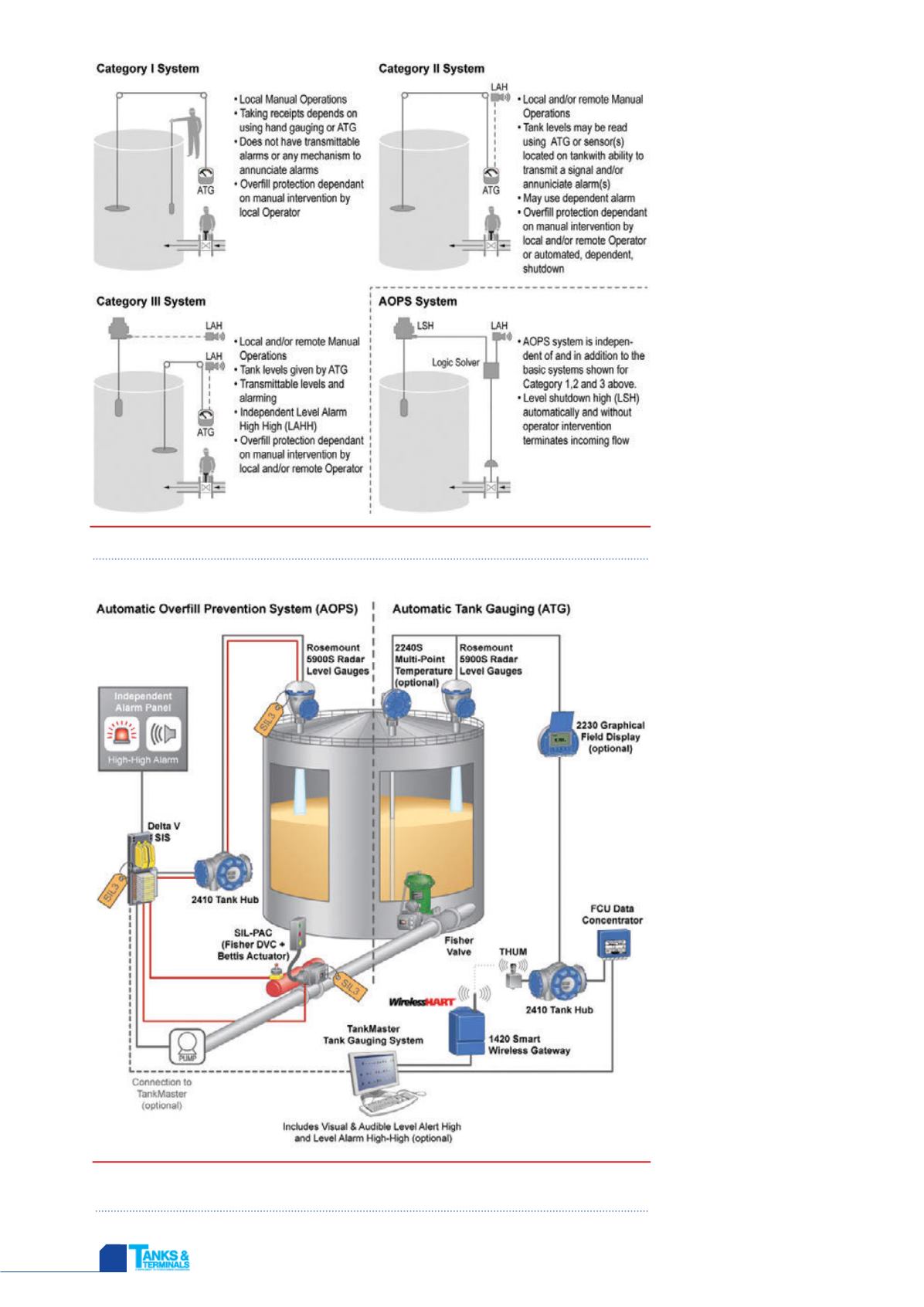

All tank farms are

different and the risks

vary based on things

like location, products

stored, tank integrity

and operational

procedures. API 2350

categorises tanks

based on attendance

level and degree of

complexity. These

categories are a

method of grouping

all the possible tank

overfill gauging

configurations into

three broad

configuration

categories. Although

the standard says

nothing about which

category is ‘better’ it

generally understood

that, the higher the

category, the more

reliable is the gauging

and alarm system:

Category 1

Category 1 systems are

essentially manual

systems such as

measurement of the

level by insertion of a

tape or rod, which

indicates the level of

oil on it. Although an

automatic tank gauge

(ATG) may be at the

tank and used for

level measurement, it

has no capability to

transmit level signals

so all information

about level is

localised to the tank.

This category should

only be used when the

risks are low (no Class

1 liquids), the receipt

operation is

infrequent, the rate of

level rise is slow and

where the operation is

so simple that an

Figure 1.

Definition of overfill protection system categories.

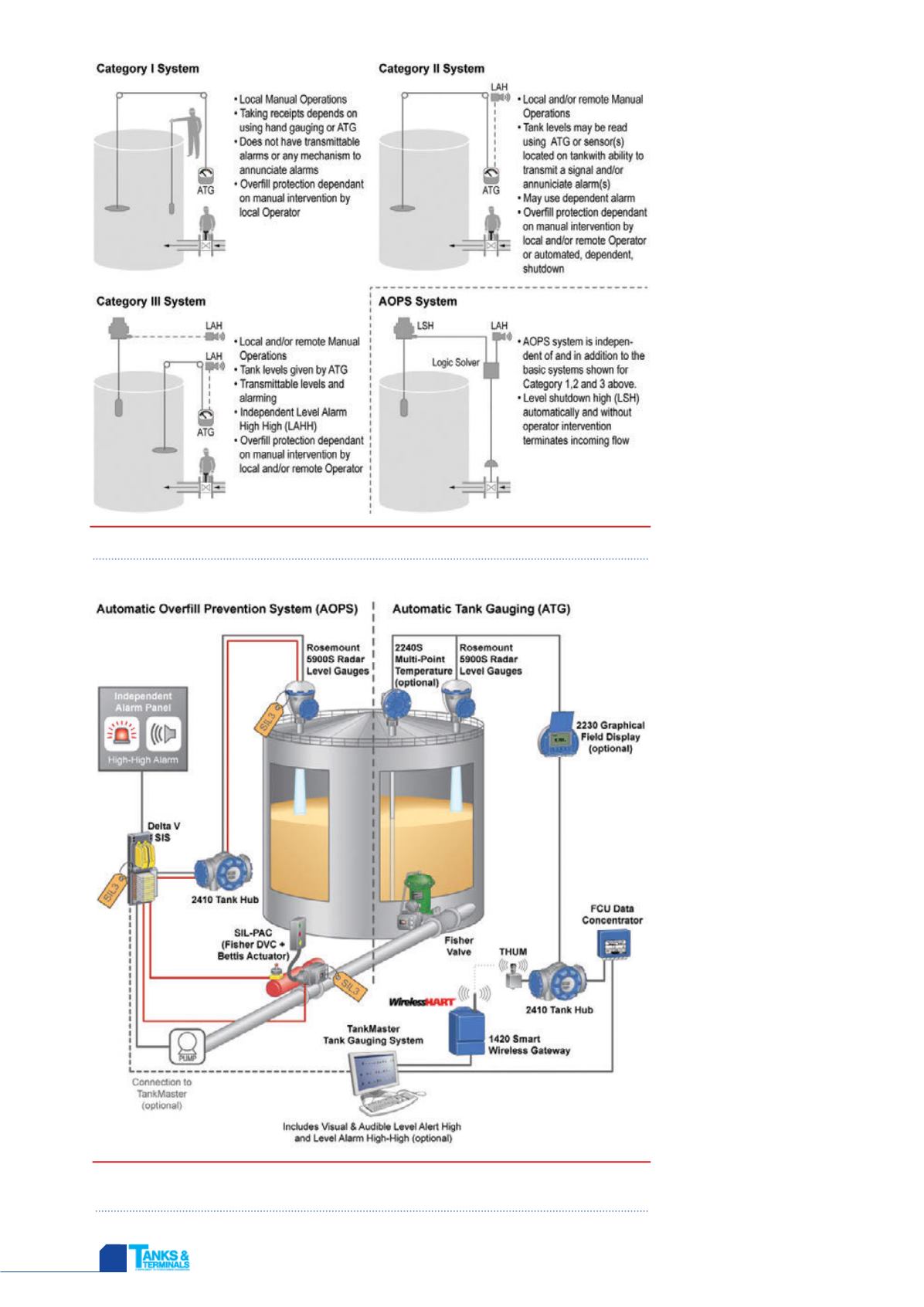

Figure 2.

Automatic overfill prevention system with powerful overfill prevention

in line with API 2350.