HYDROCARBON

ENGINEERING

34

n

Has completed an asset

register of equipment used

in the hazardous zone(s).

n

Has completed a working at

height risk assessment.

n

Has competent and trained

inspection technicians.

n

Can demonstrate

appropriate administration

of Safe Loading Passes.

The Freight Transport

Association, which manages

the scheme, completes

periodic assessments of

workshops, thus ensuring that

they meet the criteria set out

in the provider standards.

Assessments are carried out

every two years and approved

workshops receive an

authorisation to procure and

issue Safe Loading Passes.

Inspection provider

standards are flexible and

allow assessments to be

carried out for mobile

inspection providers.

Workshop assessments do not

verify or seek compliance

against DSEAR and working at height regulations (this is

the role of the UK regulator) but ensure that the

necessary risk assessments, registers and drawings have

been completed.

Inspection technician standards

Workshop technicians carry out SLP inspections and are

required to be trained against the criteria set out in the

inspection technician standards. These ensure that the

technician:

n

Understands the purpose of the scheme.

n

Understands the relevant legislation that applies

(for example DSEAR).

n

Understands how to

complete vehicle

inspection against the road

tanker checklists.

Workshops technicians’

training must be completed

every three years.

Road tanker

inspection form

Checks that must be carried

out before Safe Loading Passes

are issued are identified in the

road tanker inspection forms.

These have been developed

for:

n

Tractor units.

n

Trailer units.

n

Rigid vehicles.

Table 1.

Inspection provider standards

Workshop facilities

Control of flammable vapour releases and

sources of ignition

Only applies to inspection locations inspecting

vehicles used to carry petrol or ethanol

Working at height

Inspection pit

Inspection pits are not mandatory, but when used

for SLPS inspections, minimum standards apply

Safe storage and disposal of residual product

Tools and inspection equipment

Product colection

Overfill prevention system test units, ohmmeters,

torches, and inspection lamps used by inspection

locations inspecting vehicles used to carry petrol

or ethanol must be 'Ex' marked

Overfill prevention system test unit

Wet test container

Ohmmeter

Loading adaptor wear gauge

Specialist hand tools

Inspection technician training

Vehicle inspections

Communication of information to inspection technicians

Disc administration

Disc receipt

Disc issuance: book completion

Disc issuance: book database completion

Disc management

Liability insurance

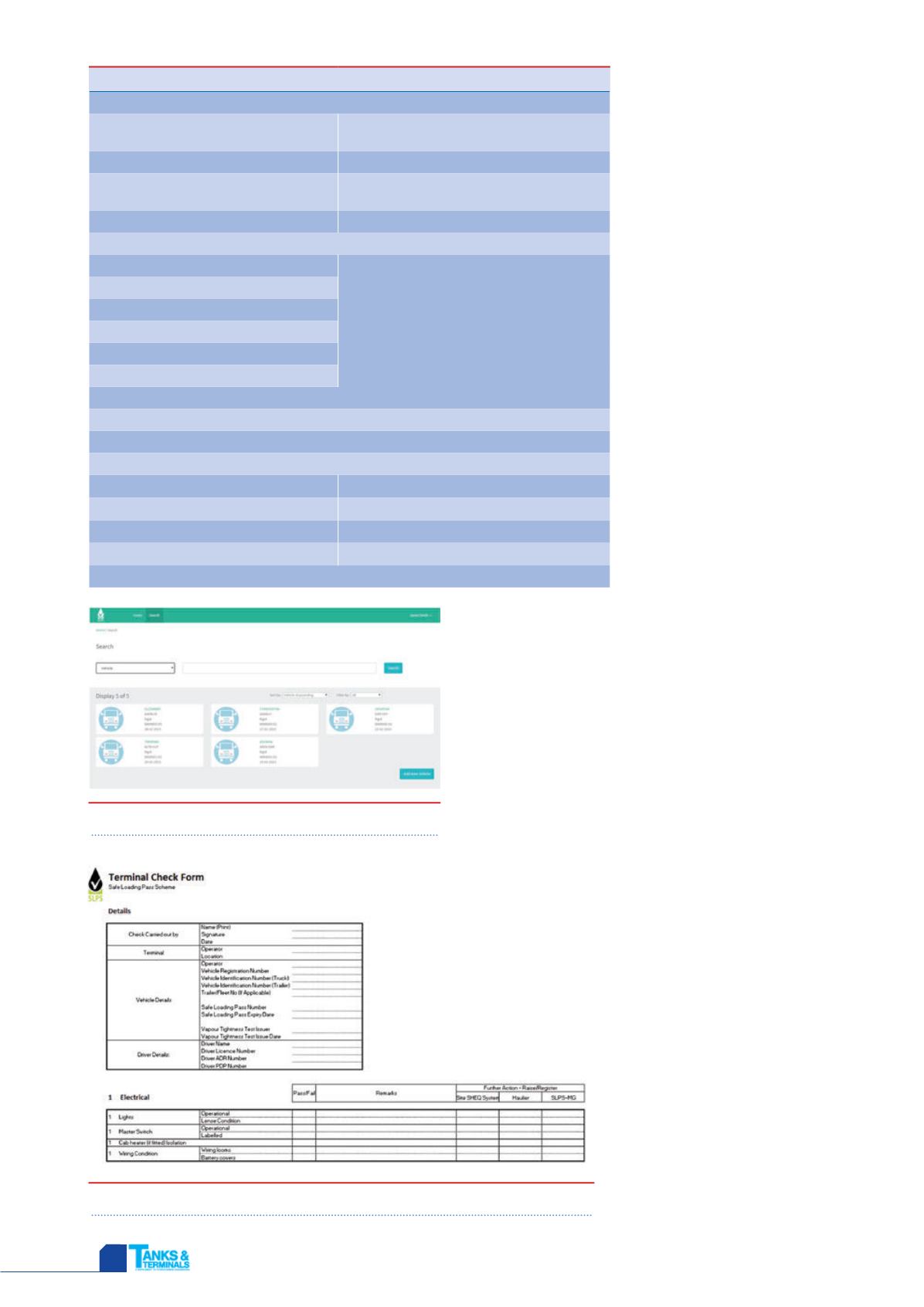

Figure 4.

Database: vehicle search results.

Figure 5.

Example terminal check form.