HYDROCARBON

ENGINEERING

24

hindered. Cost and schedule estimates decrease in

accuracy while project risk increases, which makes

awarding a contract significantly more difficult. Instead of

an owner deciding between the most optimal designs with

the best budget and schedule, they are instead betting on

which tank contractor makes the most accurate

assumptions.

For example, assume only Borings 3 and 4 in Figure 1

were done prior to invitation to bid. A conservative

assumption made by one company would include Layer H

beneath the tank. If Layer H is a soft soil such as peat, the

tank would be expected to experience large settlements, a

high liquefaction potential, and would be assigned a Site

Class E. All of these factors would require either a deep

foundation with multiple piles or a short tank

configuration.

However, when compared to the actual soil conditions

present beneath the tank, i.e., no Layer H, assumptions

based on Borings 3 and 4 are much too conservative.

Because more piles or a shorter tank are more costly and

require longer construction schedules, the owner pays

more for an unnecessary design. On the other hand, if

Layer H was present beneath the tank, but a tank

contractor assumed otherwise, the resulting tank and

foundation would be under designed for the site. However,

this error would not be discovered until after contract

award requiring a new tank design, extending the

engineering and construction schedules, and exceeding

estimates and costs.

By providing information to create an equal beginning

design basis, fewer assumptions will be made about the

soil profile and its expected performance, giving the owner

a clearer understanding of the contractors’ bids.

Potential savings of early

action and communication

Early timing of a comprehensive geotechnical investigation

is crucial not only to reduce assumptions in design, but

also to avoid the costly follow up investigation to fill

information gaps. If adequate information is not provided

during the bid process, a necessary additional survey is

done after awarding the contract to complete the design.

These additional surveys can add significant cost

(potentially up to US$400 000) and time (2 - 3 months at

the front end of the engineering schedule) to the bid cycle.

Additionally, lack of sufficient soil information can

result in critical conditions being overlooked. Voids, soft

soils, or buried debris can delay the construction schedule.

On the contrary, if conditions such as those are known

earlier via a complete geotechnical survey, mitigation

strategies can be pursued sooner in project schedules at a

lower cost.

Altogether, the potential for cost and schedule savings

can be significant. Though dependent on the site’s

conditions, a deep foundation design resulting from

minimal or delayed information can require a 3 - 5 month

construction schedule. Comparatively, a value design, such

as a shallow foundation with ground improvement,

may only take 2 - 3 months. Furthermore, the cost

differential between these two designs may range from

US$3 - 7.5 million/tank.

Therefore, the potential combined savings to the

owner could include: three months in the construction

schedule, and any additional weeks saved by discovering

obstacles prior to the start of construction, 2 - 3 months in

engineering, up to US$400 000 for avoiding a secondary

investigation, and possibly up to US$7.5 million/tank as a

result of value engineering. Overall, investing in a single

and complete survey produces a positive return for both

the project’s finances and schedule.

Minimising risk through

geotechnical investigations

The quality of the geotechnical investigation directly

affects the accuracy of the tank and foundation designs,

and therefore, the accuracy of the bid packages provided

to the owner and project developers. Without complete

information, possibly inaccurate assumptions must be

made, which may be too liberal or conservative. Even

supplementing client provided information by using a third

party introduces new variability into the design basis and

complicates the owner’s decision.

Ultimately, a complete, early, and singular party

geotechnical investigation allows for a solid design basis

that is common to all bidders. By eliminating design basis

assumptions, owners are able to make more informed

decisions when awarding the contract. Additionally, by

eliminating the need to perform late investigations,

problems are addressed earlier and more efficiently,

engineering and construction schedules are shortened, and

value engineering is pursued to create a cost efficient

design. Furthermore, the potential for expensive and time

intensive design adjustments after contract award is

curtailed and minimised.

Each of these benefits represents a reduction of risk to

the project, to the owner, and to the contractor. By taking

action early in the project development lifecycle, all

involved stakeholders are able to contribute to a more

efficient and accurate design process.

T&T

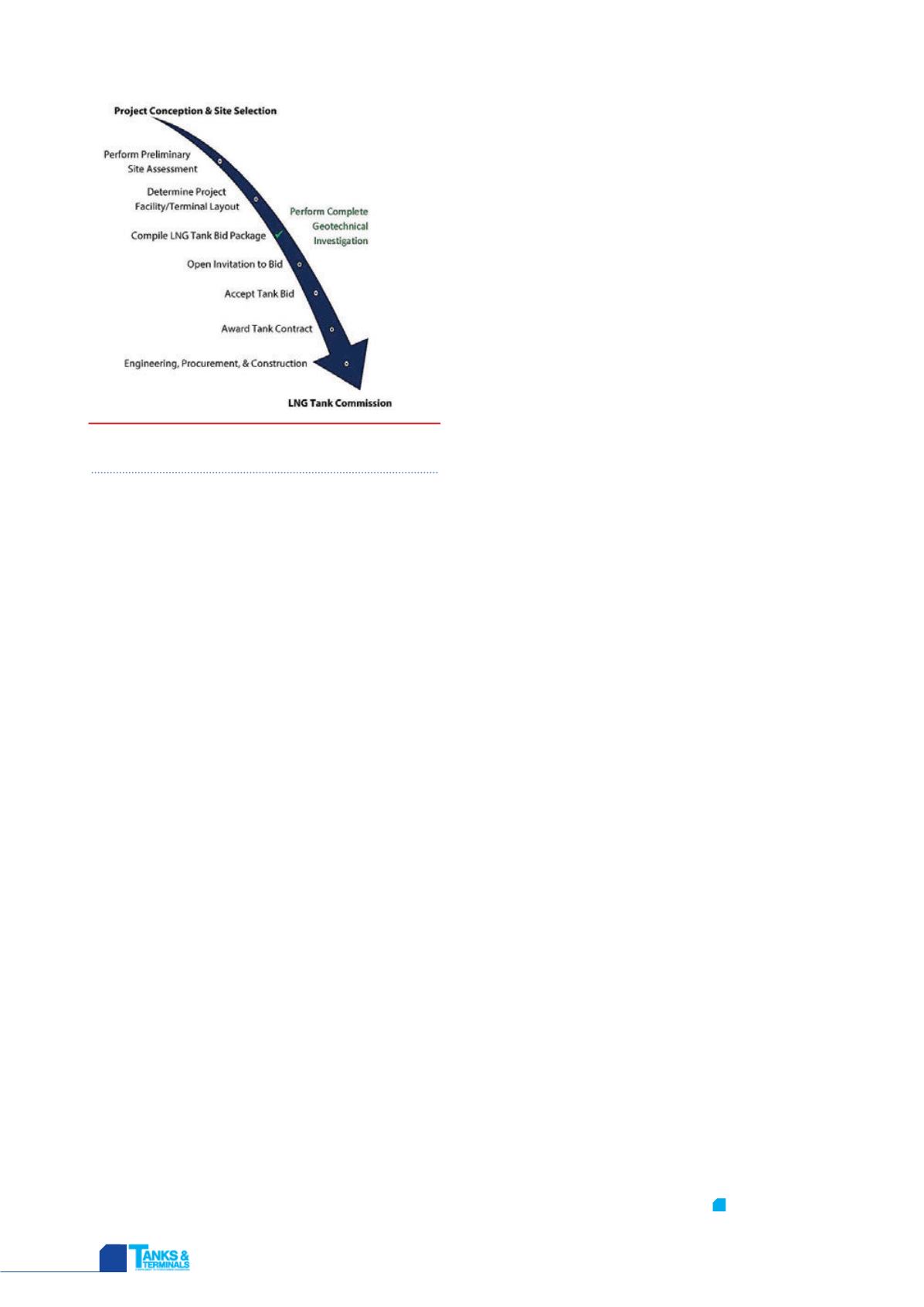

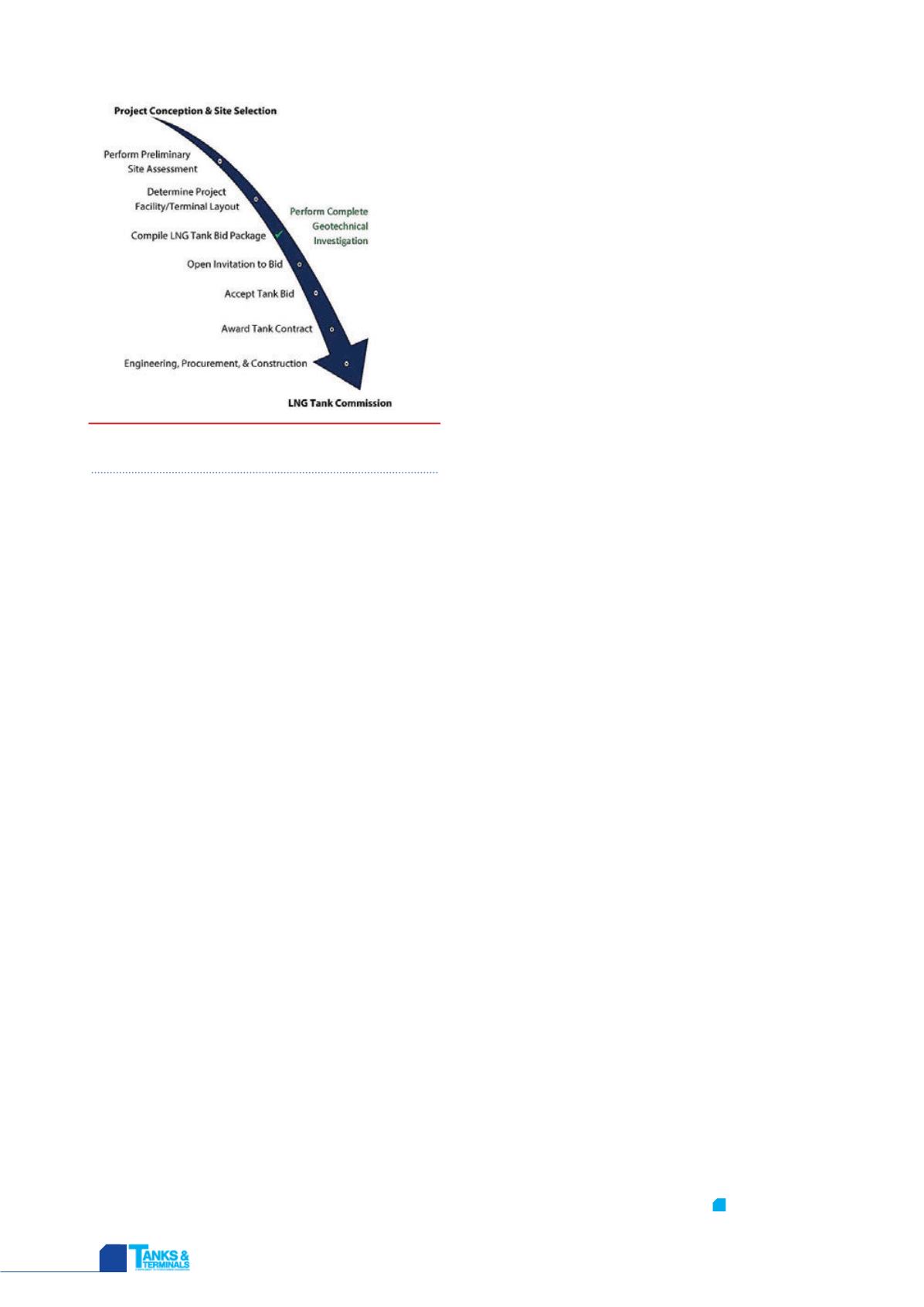

Figure 4.

Project development lifecycle and

optimal timing of geotechnical investigation.