HYDROCARBON

ENGINEERING

44

well as the need for a systems integration and data sharing

solutions approach by both vendor and customer.

Safe and mobile

So why do we not see Apple or Android apps for industrial

applications like interfacing to process and control

equipment such as tank gauges, flowmeters, and pressure

vales? The main driving reason is that trusted smart phones,

tablets, and other mobile devices are not considered safe

for use in hazardous areas such as in process plants or

around bulk petroleum storage tanks where equipment

must carry safety certifications. There are very few mobile

devices available with the required safety certifications, and

even fewer available with the range of accessories needed

for industrial tasks. These rugged and somewhat bulky

devices are supplied from a number of hardware

manufacturers. Since these companies are hardware

focused, the devices run versions of Microsoft Windows

Mobile.

Web based technology driver

This Windows Mobile operating system and its variants are

considered outdated by many web based developers

looking to make their fortune from android, windows

phone, and iPhone app sales. They are using HTML 5 for

cross platform web applications that work seamlessly on

smart phones, tablets and desktop browsers.

Looking at the example application below, one can see

why this becomes a problem. In order to perform additional

tasks (such as keyboard data entry, bar code scanning, or

credit card reading) using a hazardous area approved device

with Windows Mobile it needs to support USB and serial

communications. Not all accessories have transmission

control protocol/internet protocol (TCP/IP) interfaces,

which is the only protocol supported through HTML5. To

get around this problem, specific drivers need to be

developed and loaded onto the handheld computer. This is

not a standard task for an app store driven web developer.

I

ndustry example: Mobile hand

gauging for tank farms, terminals

and refineries

Most tank farms and terminals operate to strict procedures

governing the accountability of inventories and equipment

on site. For example, an end of month stock reconciliation

compares a hand gauge (dip) measurement against the

existing tank inventory system. This is a simple, but time

intensive process on large sites, which may be easy for

operators to take shortcuts. These shortcuts can lead to

inaccurately recording inventory. The financial value of

inventory either gained or lost impacts bottom lines every

month.

A mobile system will improve confidence in a facility’s

operations by reporting accurate, validated information

directly from the tank. Operators could be guided through

specific workflows based on the end of month

reconciliation. A well developed application would ensure

compliance and improve efficiency by asking questions

throughout the process. Data entry errors will be reduced

by scanning barcodes on equipment or by validating any

manually entered data immediately. Every data point,

whether scanned or entered, is time stamped and stored.

Information can be transferred to an inventory system at

the end of the shift or day using WiFi, cellular or a docking

station. Once transferred, office personnel can easily report

the stock position of oil and gas inventories at their tank

farm.

Understanding the application

Many processes in a plant environment are niche

applications; the number of potential users will not gain

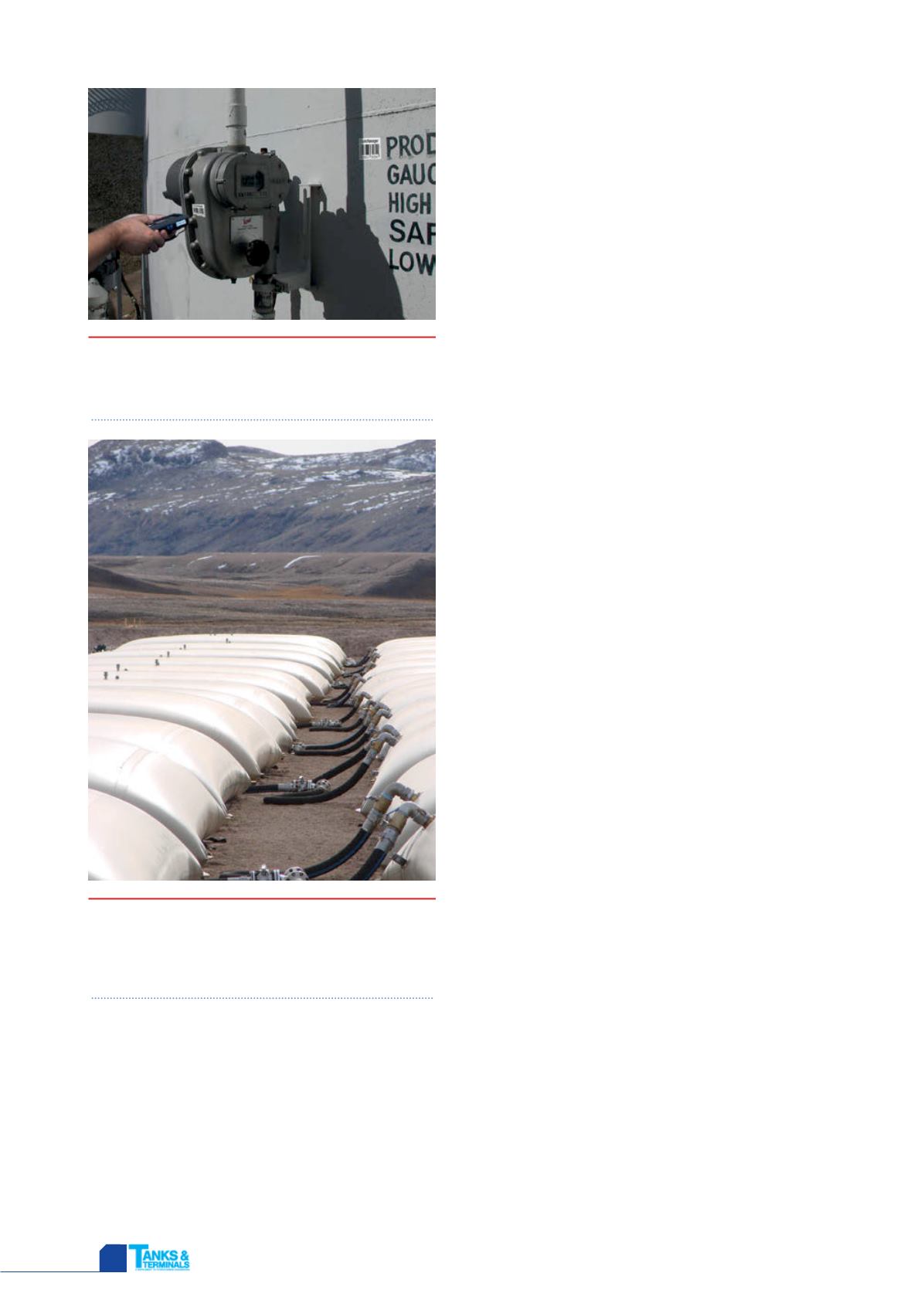

Figure 1.

Scanning a barcode on the petroleum

tank initiates the desired workflow, prompts the

operator for information, validates information

and time stamps all actions.

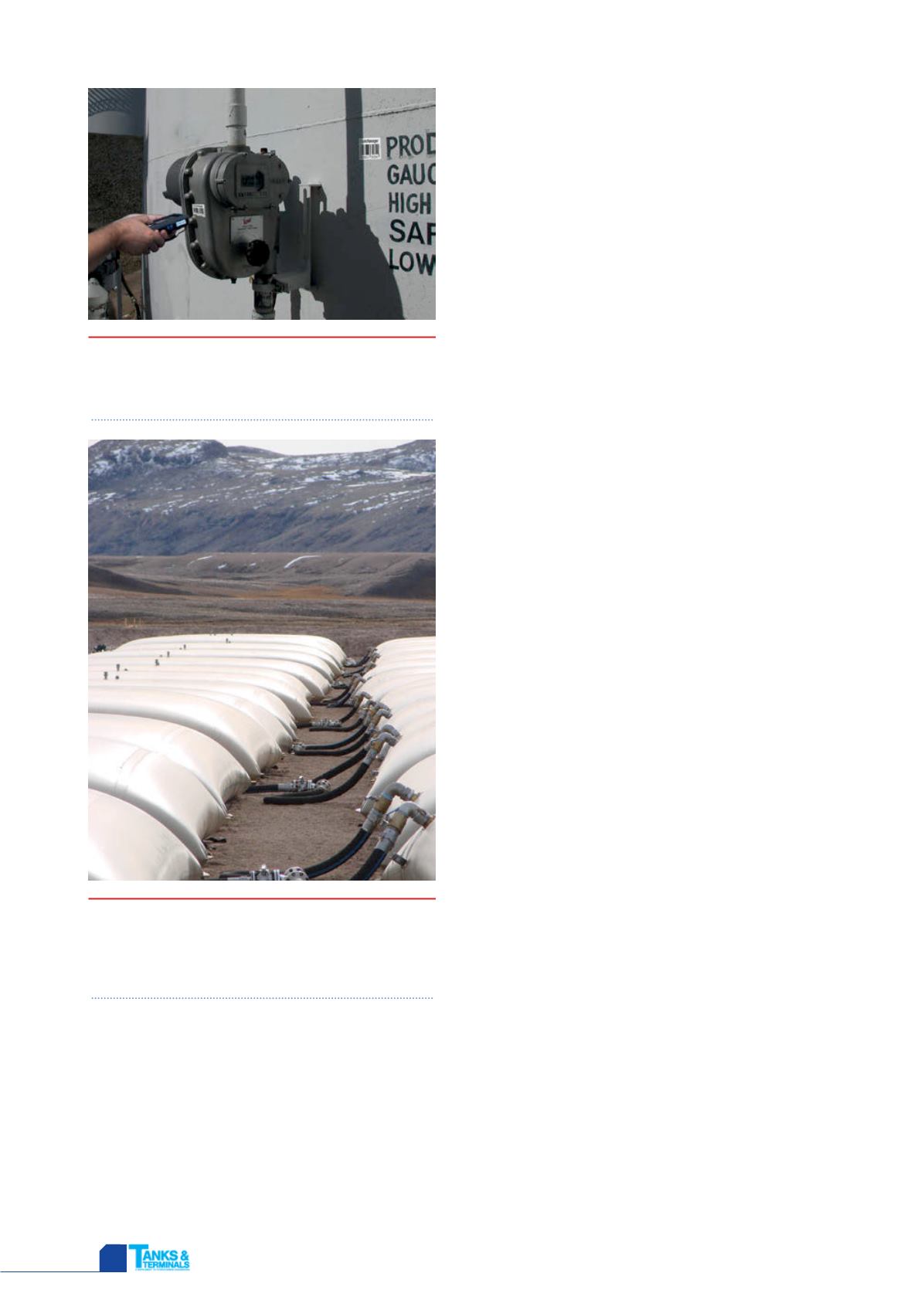

Figure 2.

Mobile computers can be used to

capture data for enterprise systems even in

remote locations, such as expeditionary or

tactical environments found in the mining or

defence industries.