that can be delivered after restarting pigging following

prolonged periods without pigging.

The requirement to return the pipeline to a clean

state is usually driven by a deterioration of the pipeline

hydraulics due to the build-up of debris, or the legal

requirement to perform an inline inspection (ILI) to

confirm the integrity of the pipeline. A lengthy period

without pigging can often be followed by launching a

standard pigging tool into the pipeline. This can result in a

stuck pig, or have a major impact at the receipt facility, if

the quantity of debris in the line is not fully understood.

This is where the progressive cleaning approach should be

employed.

Defining the programme

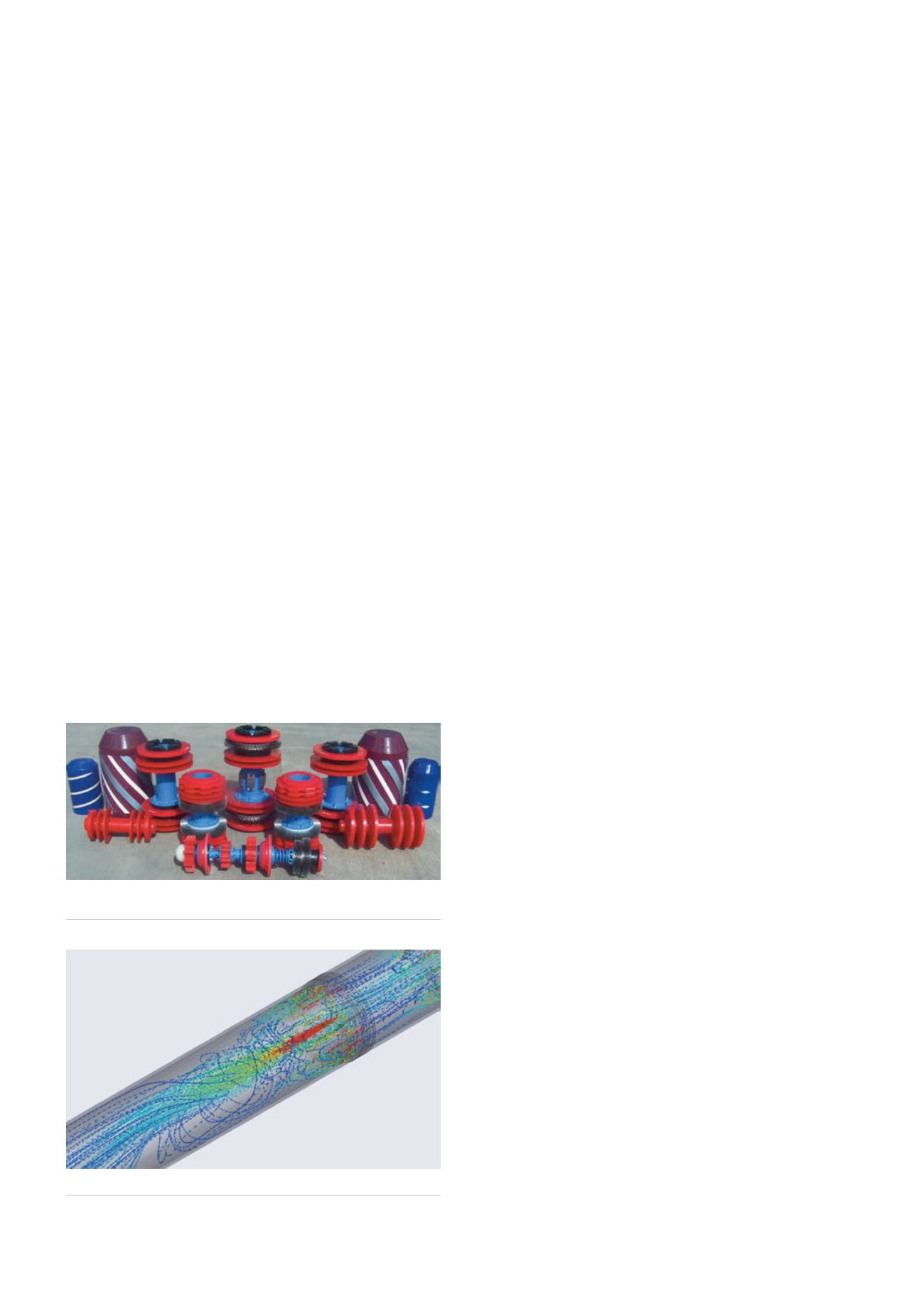

Broadly speaking, progressive cleaning consists of

the process of incrementally increasing the degree of

cleaning action applied by each successive pipeline pig

in a sequence, in order to control the amount of debris

removed from the pipeline. This control is delivered

by variations in the size and hardness of pigging tool

components. Figure 2 shows some typical examples of

pigging tools with various cleaning mechanisms.

The key to a successful progressive cleaning campaign

lies in understanding the issues to be tackled. A typical

approach is to complete a study, the output of which is a

suite of pig designs and recommendations for progressive

cleaning. In order to arrive at these designs and

recommendations, the study should include a full review

of the pipeline geometry, the pigging history (including

current pig designs used) and the operational conditions

of the pipeline. This is especially relevant for the period

without pigging.

The level of aggression of each pipeline pig in

sequence in the suite of designs will increase to enable

progressive cleaning. However, it is often the case that

the quantity of debris deposition present is not known

with any degree of accuracy. While theoretical models

can give estimates, these calculations are not well

validated. In this situation, a low aggression pig with data

logging capability can be used to verity the predicted

bore restriction. The data that is logged to enable this

is typically the pig differential pressure, acceleration,

vibration and the ambient temperature. This data can

then be fed back into the pigging programme to help

determine what level of aggression should be used to

commence the progressive cleaning. It is good practise

when increasing aggression to alter only one component

at a time on the tool. This enables the impact of the

change to be more easily understood, making the decision

to increase the level more informed. As changes are often

small, polyurethane components can be supplied with

colour coding and dimensions cast into them in order to

help the operation run smoothly.

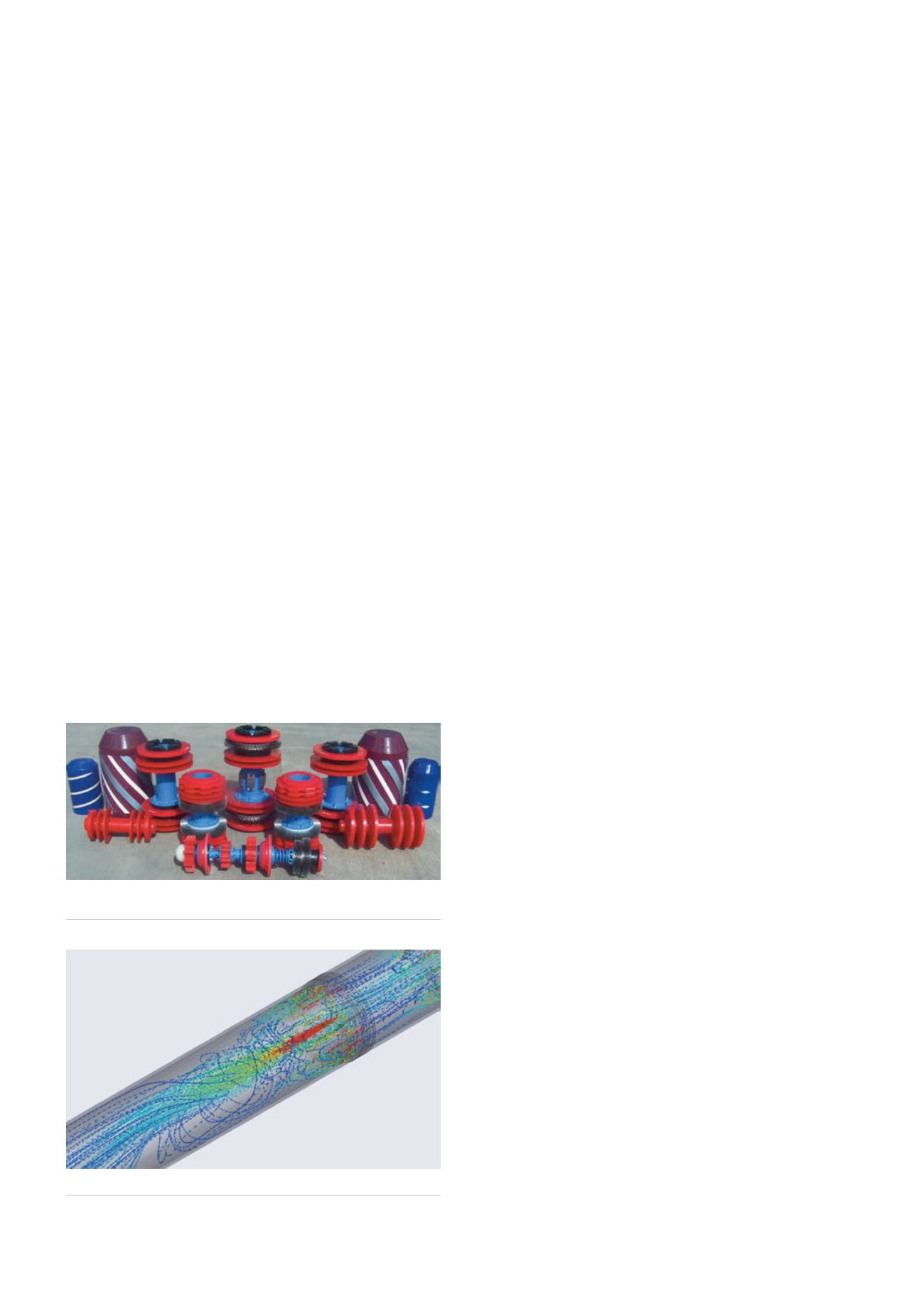

Computational fluid dynamic (CFD) calculations can

assess the effective use of a bypass through the pigging

tools. It analyses the possible level of fluid bypass

achievable through the pigging tool against the available

flowrates in the line. The process utilises models of

potential pig designs with the flow paths determined,

and tunes them for the best configuration for removal of

debris from both the pipe wall and bore, while keeping

the cleaning elements free from debris. Figure 3 shows a

typical outcome for this type of calculation.

Should there be a requirement for pig development

through testing and verification, prototype pigging

tools would be included in the study in conjunction

with a suitable test rig configuration to cover all of the

pertinent features of the pipeline. The suite of pipeline

pigs can then be tailored through empirical results rather

than relying on theory and experience alone. Testing is

often useful as a way of verifying bypass configurations

determined through CFD analyses. Deposits can be

simulated in the test rig to assess the cleaning capabilities

of the prototype pigs. The output from a testing

programme is a suite of verified pig designs and a pigging

philosophy. Figure 1 illustrates this type of pig proving

work.

The pigging philosophy is a document that should be

used during the progressive cleaning operation to assist

the operators in pig selection throughout the programme.

It will include details of any key assumptions that have

been made in the design so any changes in operational

parameters can be assessed. Specifics of the suite of

pigs with descriptions of the cleaning mechanisms and

anticipated effectiveness will be encompassed. One of

the important aspects of the pigging philosophy will be a

pig run decision tree, included to aid the operators in the

choice of which pig to run next.

Figure 2.

A selection of different types of pigging tools with

various cleaning mechanisms.

Figure 3.

Typical output of CFD calculations.

34

World Pipelines

/

JULY 2015