“Maximising use of your equipment is very

important, especially when pricing and bidding on jobs,”

said Schultz. “Making certain that every single piece of

equipment used on the job is in great working condition

and not breaking down is also essential. One of the

reasons for Waschuk’s success lies in its dedication to

making certain that all equipment on the job is in top

condition; working 100%, with no downtime is the goal.

Given their reliability and performance in the field, the

D8R-based pipelayers represent an important part of

our strategy in achieving that goal, for years to come.”

Such is their confidence in the new pipelayers,

Waschuk plans to add another 11 Midwestern

conversions to its growing fleet, increasing the total

to 52 – or roughly 70% of its sideboom fleet. Whether

working on a job for Waschuk or renting to another

contractor, the company aims to make the most of

them.

By embracing ever-changing pipeline construction

technologies and investing in ways to attract and retain

a dedicated workforce, Waschuk is doing what it always

has: preparing for the future.

Biggest contract in company history

There is a certain synchronicity in the fact that as it

enters its 50

th

year, Waschuk has just completed its

biggest construction contract in company history.

Working on behalf of Calgary’s Inter Pipeline Ltd (IPL),

Waschuk laid 330 km of pipeline from Conklin all the

way down to Bruderheim, Alberta.

Even as this operation drew to a close, Waschuk

was busy preparing for the next. As this article goes

to press, the company is waiting for the green light on

multiple projects throughout western Canada (Figure 1).

As Waschuk prepares to respond to opportunities

with drive and determination, it will continue to

stay on top of breaking technologies, government

regulations and operator developments. This means

remaining an active participant in the Canadian

mainline pipeline contractor community. To illustrate,

Kevin Waschuk served two terms as President of the

Pipe Line Contractors Association of Canada (PLCAC)

and has been a member of its board of directors

for 17 years. The company is also a vocal advocate

of industry-wide initiatives, such as the Pipeline

Workforce Attraction Project sponsored by the

PLCAC, the four pipeline craft unions and the Alberta

Government.

“You can’t operate in a ‘bubble’ and expect to win

work and execute it well. You have to be in touch,”

said Kevin Waschuk. “If I could sum up the secret to our

success, it would be that in addition to staying current,

we have the experience, the equipment and the know-

how to get the job done. And we plan to keep doing

just that.”

ALLU Finland Oy

Email:

Tel: +358 (0)3 882 140

Fax: +358 (0)3 882 1440

Jokimäentie 1, 16320 Pennala, Finland

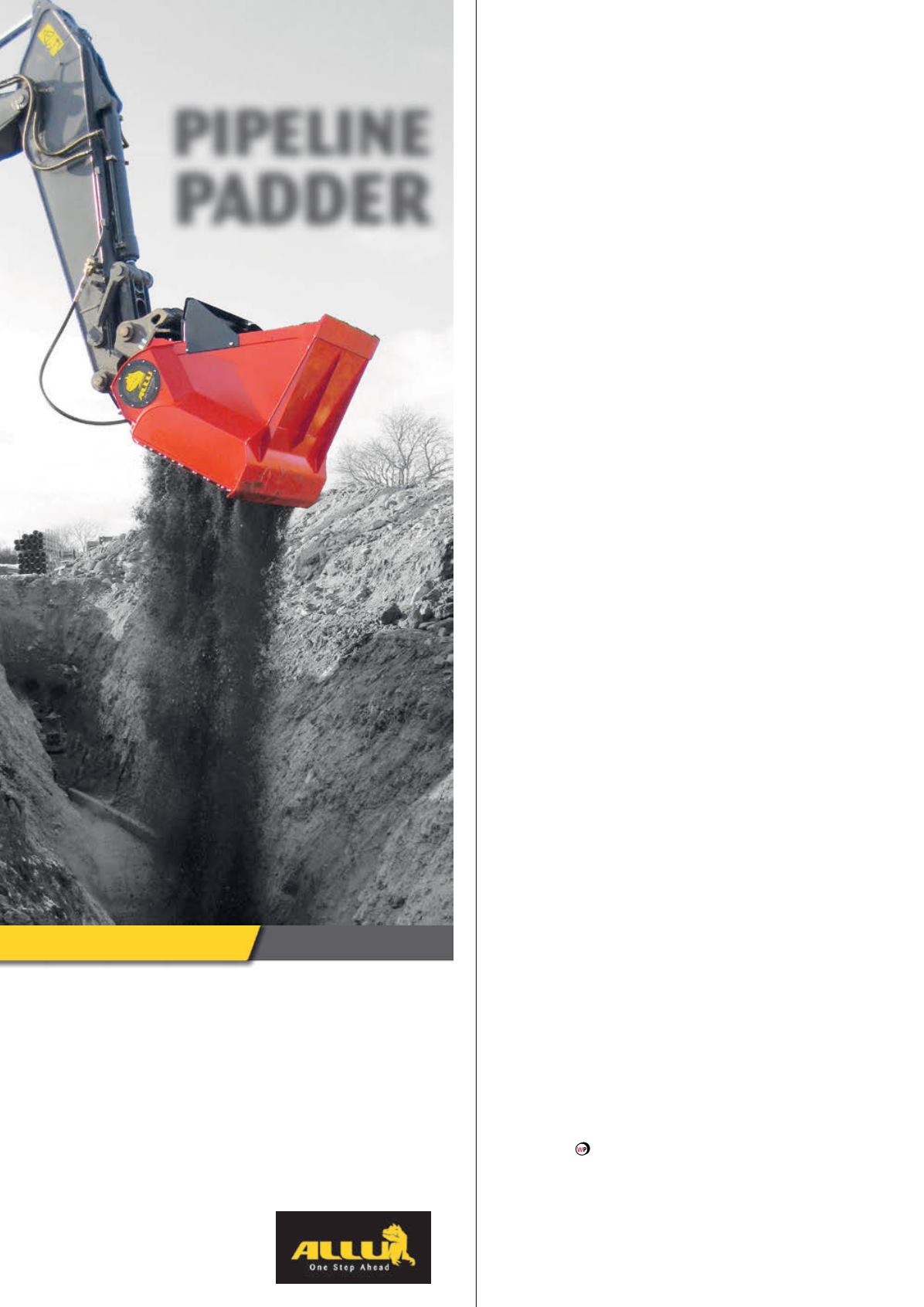

PIPELINE

PADDER

MOBILE

pipelinepadding.com

SAVE MONEY WITH ALLU

- NO NEED TO HAUL IN BEDDING MATERIAL

With mobile ALLU padder you can screen the excavated

material back to the trench. You no longer need trucks

to transport excavated material from the site and haul in

new bedding material.