first pipeline was swabbed out with a wad of straw bound in

barbed wire more than a century ago.

Keeping the juices (and gases) flowing

Today, pigging still means clearing a pipeline of debris and

residue. But that’s not all: inspection, testing, gauging, batch

separation, displacement, dewatering, drying, filming (coating

interior walls of a pipeline) and other applications require

specialised pigs of many sizes and shapes, and constructed of

various materials.

As always in the business world, success means finding

a need and providing a solution. Two North American

companies have done just that.

The heart of Canada’s oil and gas pipeline network is in

Alberta. Amongst the key players of a burgeoning energy

supply and service industry is Apache Pipeline Products of

Edmonton. Apache was formed in 1986 and quickly became

a leading manufacturer of pipeline cleaning and maintenance

equipment. The company’s 36 000 ft

2

facility satisfies all of

the industry’s needs, including custom polyurethane-moulded

requirements. Its product line includes foam and solid cast

urethane pigs, scraper cups, jetting cups, conical cups, guide

and sealer discs, and gauge plates.

“Our tag line is ‘World Class – World Wide’ and we take

pride in manufacturing high quality products and providing our

customers with excellent service,” says Don McNabb, Director

of Sales, Apache Pipeline Products.

Apache’s flagship product is the patented Apache pigPRO

Intrusive pig passage Indicator. It is available in three models;

the basic Series 57 is a visual flag indicator with manual reset.

It includes a thread mounting nipple, standard lower housing

with fluorocarbon O-rings, and a hemispherical plunger with

a flag assembly. Series 55 is an electrical indicator with an

automatic reset. It includes the same features as the 57 series

without visual flag but has a weather-sealed explosion-proof

micro switch. The Series 53 is a combined visual/electrical

indicator with manual/automatic reset. It has the same

features of the 57 and 55 series as well as a weather-sealed

explosion-proof limit switch. The switches on both the 55 and

53 series are NEMA rated, UL-listed and CSA-certified to suit

most applications.

All three are available with optional flange base mounting,

manufactured to mount to existing flanged connections

and are available in class 150, 300, 600, or 900 ANSI flanges.

Conversions kits are also available that enable installation

onto the mountings of other manufacturers.

It’s 3 AM. Do you know where your pigs are?

But it doesn’t end there. A pigging mission isn’t accomplished

until the pig is recovered and the pipeline is back in business.

With so many pigs circulating through the world’s pipelines,

somebody, or something, has to keep track of them. That

‘somebody’ is CDI in Oklahoma, USA, deep in the heart of

America’s pipeline country. While Apache was perfecting its

product line, CDI was busy developing an electromagnetic

transmitter for pigs.

Such a transmitter had to be rugged enough to withstand

the pressures, temperatures and materials of a pipeline

environment. It had to be powerful enough to send a

surface-detectable signal yet offer low power consumption.

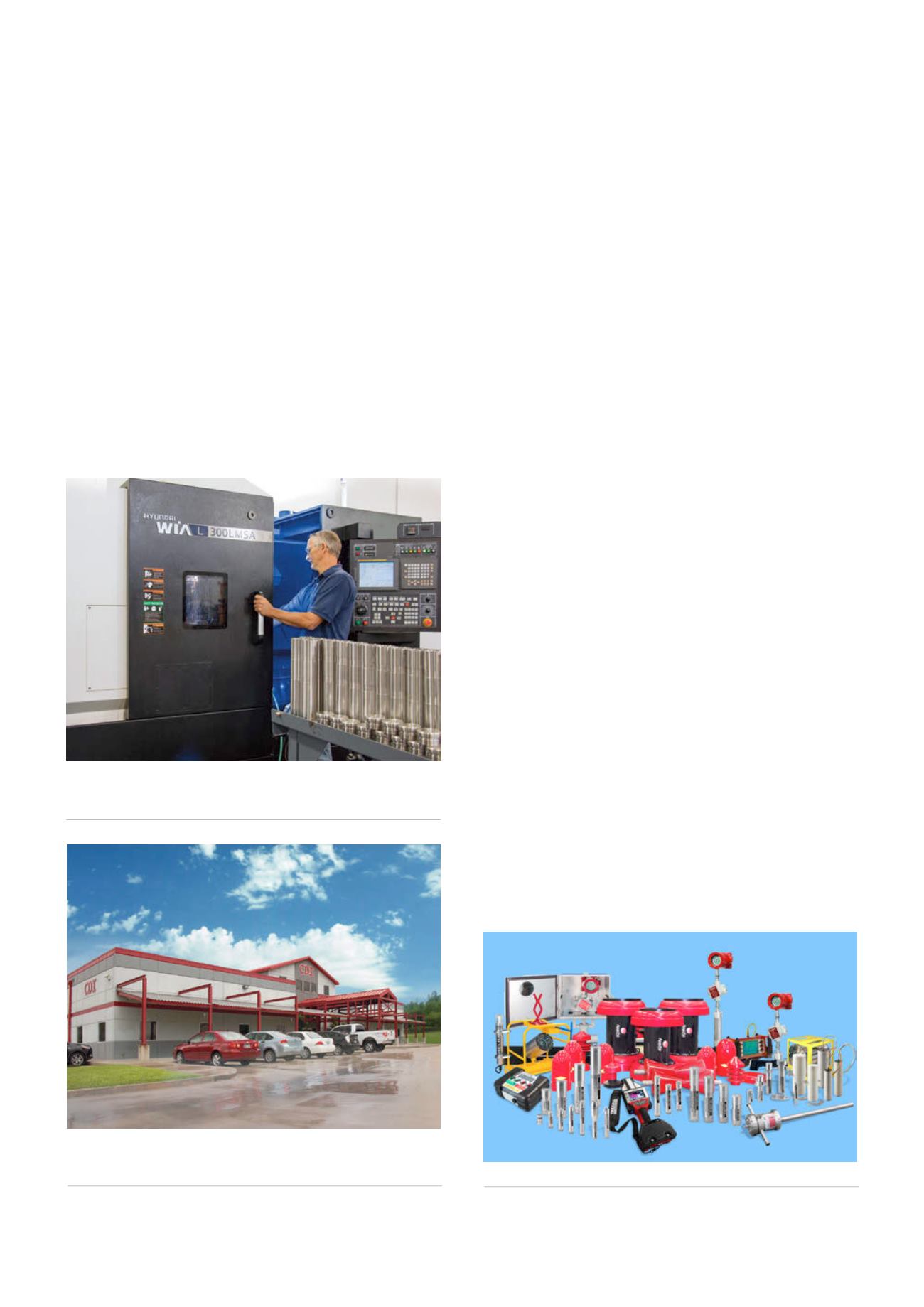

Figure 1.

Like all CDI products, these pig tracking transmitter

cases were built completely in-house on one of six fully-

automated CNC machines.

Figure 2.

CDI Headquarters, Broken Arrow, Oklahoma has

recently expanded to accommodate production, inventory, and

a training facility.

Figure 3.

Just a few of the many Apache and CDI products.

30

World Pipelines

/

JULY 2015