)

)

Cleaning in a single pass, saving time.

)

)

Enhance mechanical pig performance, pig lubrication,

reduced bulldozing of debris and less risk of pig sticking.

)

)

Verifiable estimate of debris removed and remaining.

)

)

Useful in critical applications such as black powder removal

before inline inspection.

Versatile materials

To provide the best performance, Aubin pipeline gels are based

on a variety of fluids such as freshwater, seawater, hydrocarbon,

finished product (e.g. diesel) organic solvent, alcohols and

glycols. Aubin’s MEG Gel is particularly useful in spool filling

during pipeline construction, where the reduction of ingress

helps prevent problems after commissioning caused by water,

chloride ion or debris contamination.

Aubin has recently developed both hydrocarbon-based

and environmentally friendly water-based gels to provide

improved performance in resistance to dilution and debris

carrying performance in variable pigging speed scenarios. In

the past, pipeline gels have occasionally failed to adequately

suspend and carry heavy debris out of the line due to

dilution, bypass, or picking up excess fluid in the debris.

This can cause the theological properties of the gel to

deteriorate until suspension of the debris is compromised.

Similarly, there have been problems reported when the pig

velocity falls below the optimal pigging speed of 0.5 - 2 m/s.

This can provoke the sedimentation of debris in some gels

where there is insufficient turbulence to keep the debris in

suspension. The consequence is a debris concentration at

the 6 o’clock position, which can then accumulates in front

of a mechanical pig, to the extent that it may stick – very

undesirable. In contrast, Aubin’s Pipeline Gel DP can suspend

heavy solids at a wide variety of pig speeds, and can tolerate

50% dilution and complete flow shut down. Suspending

debris for prolonged periods; the pipeline gel train may

even be ‘parked’ for periods of hours, even days, without

significant debris drop out. Aubin’s hydrocarbon-based

petrogel fluids provides similar options when water-based

fluids are undesirable. They normally utilise diesel as the

base fluid, although other hydrocarbons and solvents can be

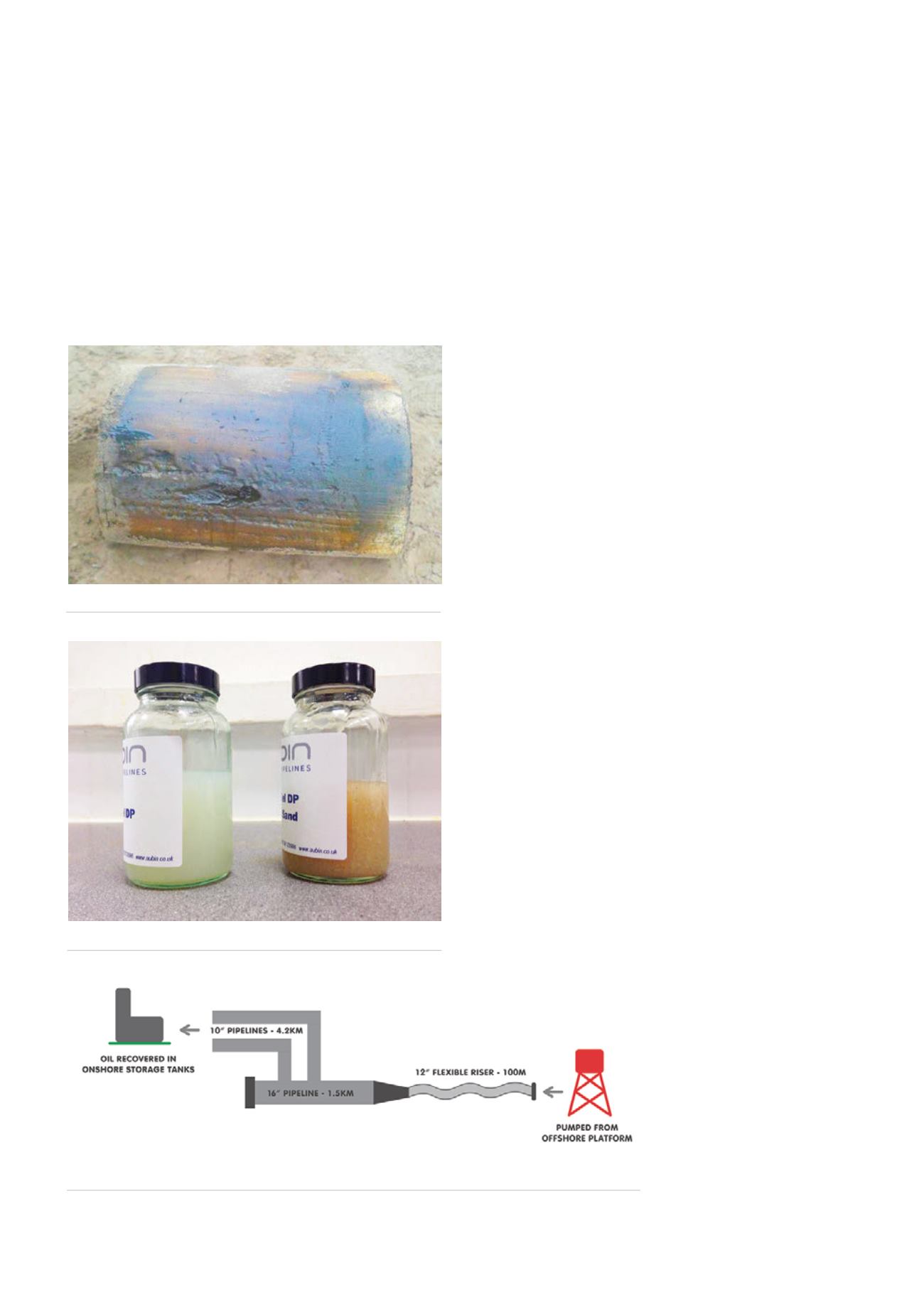

used following testing. Figure 4 shows standard Petrogel DP

next to an identical sample containing 10% of debris (sand).

After 24 hours static, no sedimentation of debris has taken

place.

De-oiling

A Middle East offshore subsea pipeline system consisting of

two 10 in. pipelines and 16 in. header was being repurposed

to provide water for emergency firefighting, therefore it was

necessary to maximise oil recovery from the line prior to use

(Figure 5).

Aubin’s water-based separator gel, Pipeline Gel 33, was

used due to the high viscosity of the oil (up to 140 cSt at 50˚C).

The gel was supplied in its concentrate form to aid transport;

6000 litres of gel was produced, cross-linked and injected

through the 12 in. flexible riser and into the 16 in. header.

Treated seawater pushed the

slug into the two 10 in. lines

and finally to onshore storage

tanks. The line was successfully

de-oiled and 344 m

3

of residual

crude oil recovered. The use of

Aubin pipeline gel had other

advantages: a reduction in the

time required to meet oil in

water specifications; reduced

water and treating chemical

consumption; and lower liquid

processing and disposal costs,

Figure 3.

EVO-Pig after removing post.

Figure 4.

Petrogel DP sand suspension, 24 hours static.

Figure 5.

Gel assisted de-oiling, field diagram.

42

World Pipelines

/

JULY 2015