Running the programme

When it comes to running the progressive cleaning

operation, the pigging philosophy is the document

around which decisions should be made. The decision

tree should be used to determine whether or not the

next most aggressive tool should be run, or the same

level of aggression maintained. Decisions will be based

on run data in comparison to what was seen during any

testing, and levels of debris received and the impact of

this on the process. The pipeline pig supplier should be

available to review feedback and offer advice in line with

the decision tree process. It is quite common for pigging

companies, such as Pipeline Engineering, who offer this

level of product support for specific applications, to also

provide optional and additional pigging services including

the supply of site based engineers and field service teams

to assist with the progressive cleaning operations, and

offer advice based on first hand observations.

Pipeline cleanliness assessment

The aim of a cleaning campaign is usually to either

prepare the pipeline for an inline inspection or improve

the pipeline hydraulics. It is beneficial to confirm the

cleanliness of the pipeline to confirm either of these

objectives has been met. This is particularly important

prior to running an inline inspection tool as these tools

require a good contact between the sensors and the

metal pipe wall in order to work effectively. This in

turn requires a clean pipeline. There are considerable

costs associated with having to undertake a repeat ILI

tool run, therefore confirming the pipeline cleanliness

prior to running the intelligent tool is advantageous. It

is standard practice to run a pipeline pig equipped with

an aluminium gauge plate, but this is only capable of

confirming that there are no major restrictions to the

bore of the pipeline.

Traditionally, the decision of whether or not to run

the ILI tool is based on analysing the quantity of debris

returned from each pig run and making a judgement call

as to whether the line is clean enough to facilitate a

successful ILI tool run. This is often made more difficult

as many operators flush the receiver after pig receipt, so

the debris present when the trap is opened is not always

representative of what has been returned. Pigging based

inspection tools, such as Pipeline Engineering’s patented

PECAT™, that are specifically designed to assess the

cleanliness of pipelines are available. The sensor and data

logging capabilities of PECAT enables measurement of

location and quantity of debris in the line as well as other

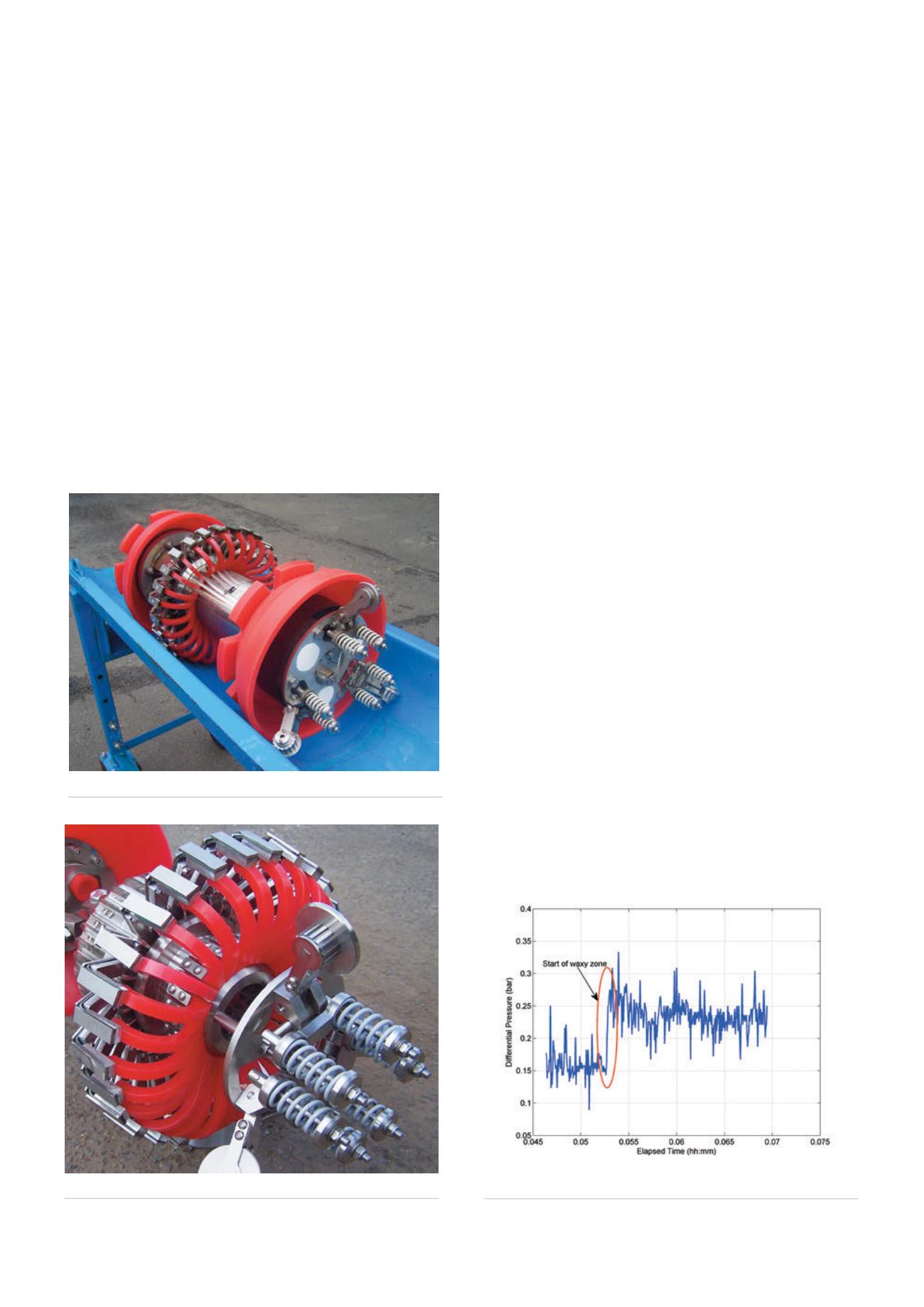

parameters if required. Figures 4 and 5 show examples of

PECAT.

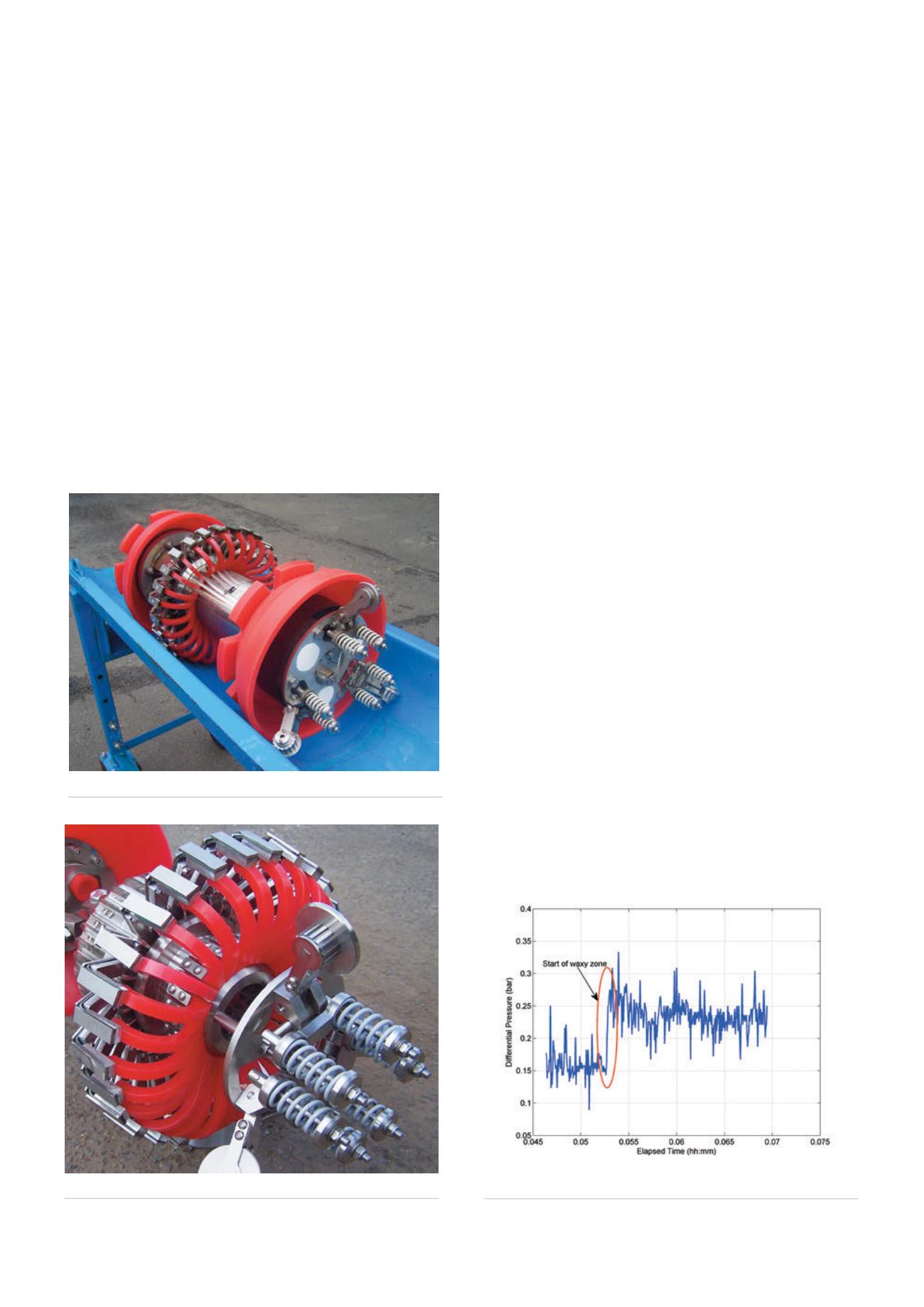

The main data that is logged with regard to debris

assessment comes from the pipe wall offset and rotation

sensors. Additional data that is logged to support

cleanliness assessment is the pig differential pressure,

acceleration, vibration and the ambient temperature. The

information reported can then be used to make a decision

Figure 6.

Typical differential pressure trace.

Figure 5.

PECAT™ sensor arms and odometer assemblies.

Figure 4.

PECAT™ – Pipeline Cleanliness Assessment Tool.

36

World Pipelines

/

JULY 2015