“Quality, ongoing training pays off on every front. We

find that a well-trained, carefully developed workforce

enhances company performance,” said Kevin Waschuk. “If

the job is performed efficiently, is in line with customer

expectations and carried out safely, it’s a win-win situation.

When the customer is happy, we’re happy, with employees

reaping the benefits of a job well done, and the cycle

continues.”

Attracting Generation Y – the technology

factor

To attract Generation Y – those born between 1980 and

2000 – it is important to understand them and what

motivates them. This generation takes state-of-the-art

technology for granted, along with 24 hour web access

and smartphones. They actively seek out ways to develop

their careers with companies that offer not only attractive

compensation, training and benefits packages, but are in

touch with the latest industry trends. In the construction

industry, they gravitate to those that invest in heavy

equipment that is reliable, safe and extremely user-friendly.

With its eye on the future, Waschuk knows that to recruit

the top talent of this younger generation, it must respond to

their expectations. One of the ways Waschuk is doing this

is to make certain that much of its fleet is extremely user-

friendly.

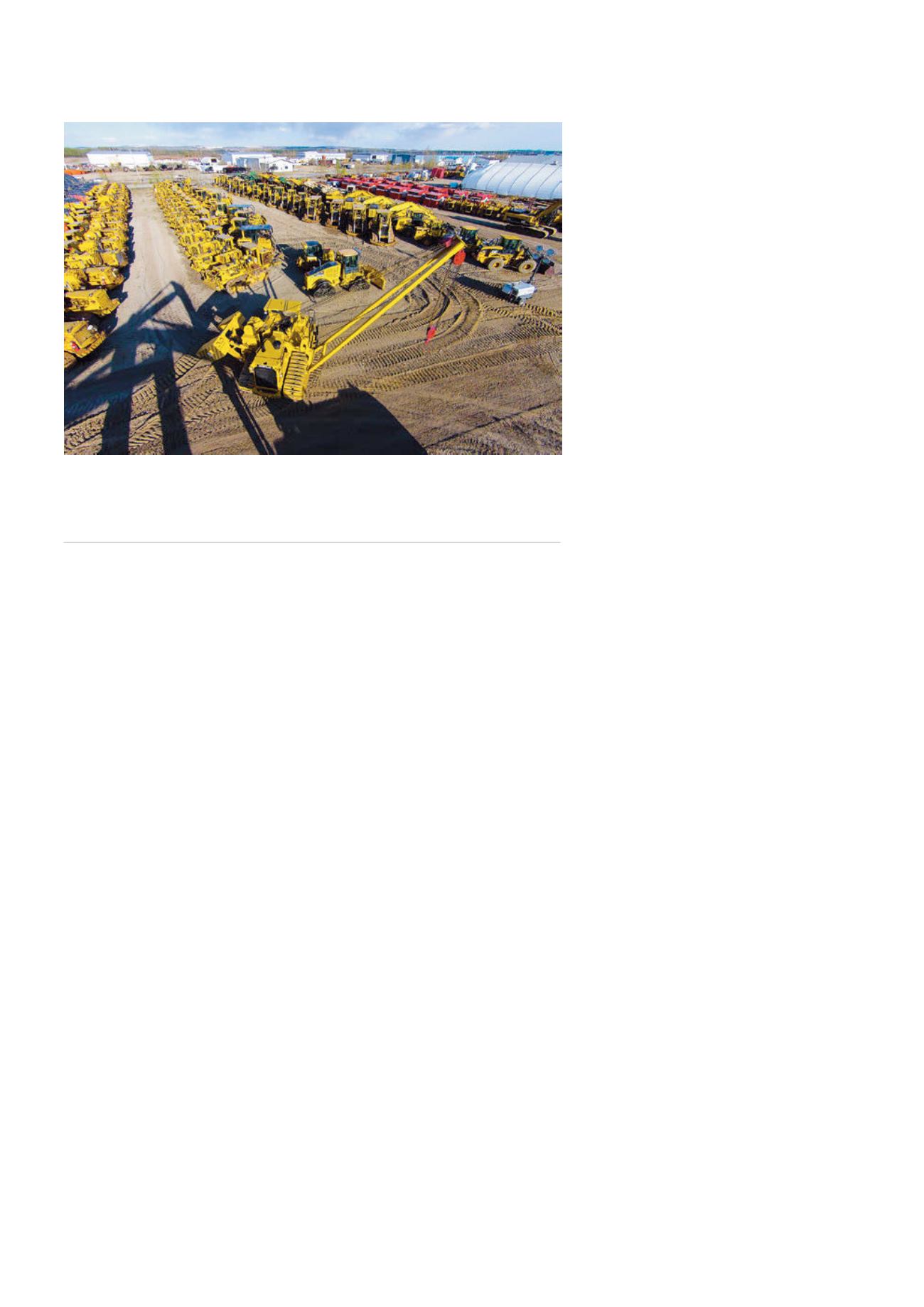

Earlier this spring, Waschuk took delivery of its first

converted Caterpillar D8R tractor equipped with Midwestern

Manufacturing’s new M583CH sideboom attachment

(Figure 4). By doing so, Waschuk is using a pipelayer that is

easier to operate; one that the computer-savvy generation

finds easy to learn because the sideboom is operated with

integrated joy stick controls. “For those about to retire, it

seems strange to look at the operator station and not see

the complex range of levers, but for our

new hires, it’s business as usual,” said Kevin

Waschuk.

Newly designed pipelayer offers

improved visibility, safety and

affordability

Attracting eager young talent was not the

only thing that motivated Waschuk to fit the

D8R dozer with a state-of-the-art sideboom.

“First, we consider the sideboom – and its

role in the pipelaying process – to be the

most important piece of the pipelaying

equipment spread,” said Trevor Schultz,

Equipment Manager for Waschuk. “Secondly,

from a business standpoint, we assessed our

fleet of D8R dozers in terms of lifecycle,

usability and resale value. Because they’re

extremely durable and still in great working

condition, we decided that rather than sell,

we would update and convert them.”

“But we didn’t want to fit just any

sideboom on it. After talking to numerous

operators over the past two years, we

decided to pursue a sideboom for the D8R. With the dozer’s

higher centre of gravity, we knew it would be challenging,

especially because it was critical that it be as safe and user-

friendly as possible. To achieve that, we knew we could rely

on Midwestern Manufacturing.”

Waschuk shares a positive, long-term relationship

with Tulsa-based Midwestern Manufacturing, the world

leader in sideboom attachments. Over the past 10 years,

Midwestern has supplied the company with 22 wet kits

and a dozen dozer-to-sideboom conversion kits. Given

the way these sideboom kits have performed in terms

of reliability, safety and usability, it was only logical

that Waschuk turn to Midwestern to fit the D8R with a

sideboom attachment.

“As fate would have it, when Waschuk contacted us

about converting their existing fleet of D8R tractors into

sidebooms, we already had plans in place to update our

existing M583CH design. So, the timing couldn’t have

been better,” said Joe Beffer, Executive Vice President of

Midwestern Manufacturing. “Drawing upon their research

and experience, Waschuk provided valuable feedback and

were supportive of the direction we were going with the

new design.”

The D8R tractor has proven to be a solid platform for the

hydraulic sideboom. The new design offers electrohydraulic

multi-functional joystick controls and a high capacity

pipelayer winch package with piston motors. Coupled with

the higher visibility afforded the operator and the ability to

update it with new technology, such as load monitoring, it is

very user-friendly and extremely adaptable.

For Waschuk, the D8R conversion is an economically

sound decision: for just a bit more than a quarter of the cost

of a new unit, the company has a well-engineered, purpose-

built pipelayer with a working life of 30 plus years.

Figure 4.

In spring 2015, Waschuk took delivery of its first converted Caterpillar

D8R tractor equipped with Midwestern Manufacturing’s new M583CH sideboom

attachment. With its enhanced operator visibility and ability to be updated with

new technology, such as load monitoring, it’s very user-friendly and extremely

adaptable.

22

World Pipelines

/

JULY 2015