contractors’

directory

2015

REHAB

FEASIBILITY

STUDIES

WELDING

MAINTENANCE

COMPRESSOR

STATIONS

HORIZONTAL

DIRECTIONAL

DRILLING

TERMINALS

46

ONSHORE

PIPELINES

company name

RESEARCH &

DEVELOPMENT

FINANCE,

STRATEGY

& ANALYSIS

TURNKEY

CONSTRUCTION

OFFSHORE

PIPELINES

C ntinental Fabrication Services

Continued

coating, painting, and QA/QC practices. The QA/

QC team inspects material before any fabrication

begins to make sure it is without defect and

up to customers’ standards, and establishes a

documentation record, which is maintained until

the product arrives for installation.

CFS’ team includes a Professional Engineer, QA/

QC Auditor and Certified Welding Inspector. All

welding procedures are documented, tested, and

surpass ASME and API 1104 standards. Coating and

painting work is completed and documented by

NACE certified personnel.

Expertise and experience combine to form CFS’

high quality, efficient and timely fabrication team

that shares a common goal of providing clients with

the most complete, cost effective and timely delivery

of pre-fabricated assemblies in the industry.

Recently completed or ongoing oil and gas

pipeline projects:

F

Six 36 in. pump stations.

F

Three 24 in. pump stations.

F

Hydrotested 5000 ft of 26 in. pipe.

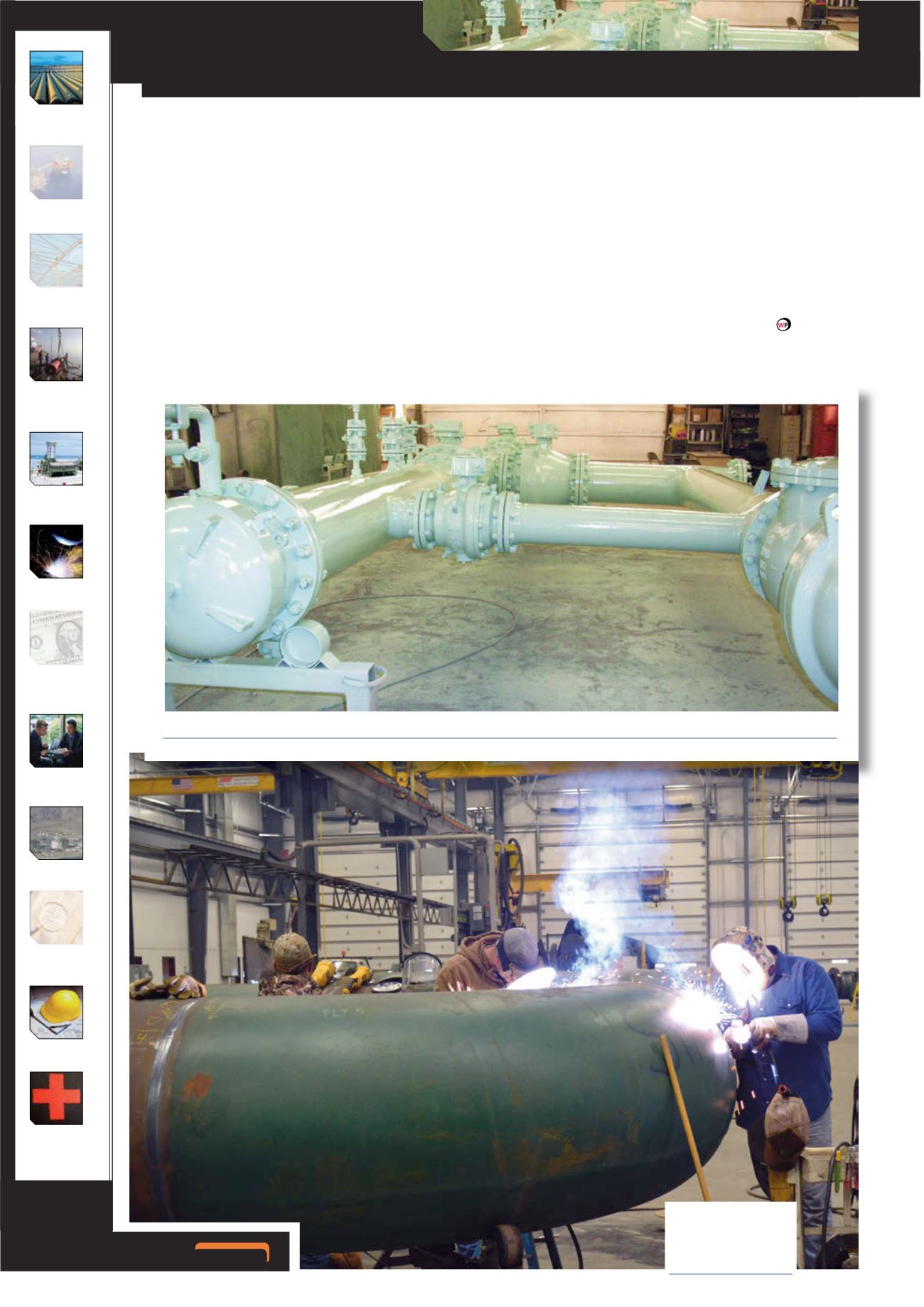

A complete pipe is ready to be shipped to a job site.

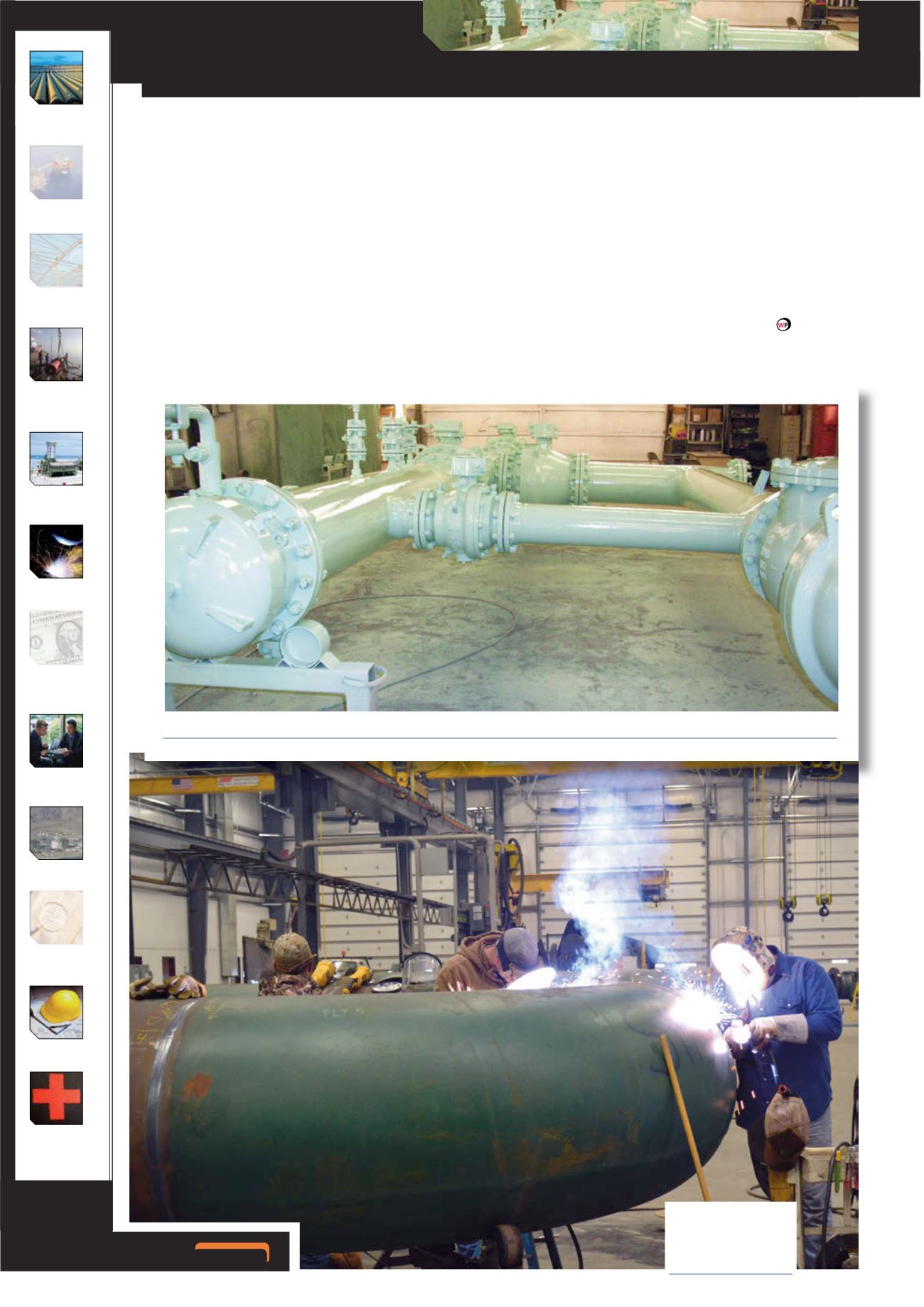

CFS crew members

weld a pipe to the

customer¹s exact

specifications.