contractors’

directory

2015

HORIZONTAL

DIRECTIONAL

DRILLING

OFFSHORE

PIPELINES

52

ONSHORE

PIPELINES

REHAB

MAINTENANCE

RESEARCH &

DEVELOPMENT

TERMINALS

FEASIBILITY

STUDIES

FINANCE,

STRATEGY

& ANALYSIS

WELDING

COMPRESSOR

STATIONS

TURNKEY

CONSTRUCTION

CRTS

C

RTS, Inc. is committed to preventing internal

pipeline corrosion by making new pipelines’

weakest links become the strongest links. CRTS’

robotic equipment applies protective coatings

to internal field joints, strengthening and complementing

typical corrosion prevention methods such as internal

and external pipe coating. Internal field joints are cleaned

and coated, and real-time video reveals any defects

before any product is

in the pipe. The group’s

innovative inspection

techniques detect flaws

in pipeline coatings before

any product enters the

pipeline.

After cleaning and

coating the internal field

joints, CRTS provides

state of the art visual, high

voltage holiday and dry film

thickness inspection services

that incorporate real-time

video. The inspection robot

also contains technology

to view and record the

radial location of any

coating holidays and displays

parent-coating damage,

debris, failed field-applied

couplings and other

anomalies. CRTS’ unique

custom coating equipment

allows coating of internal

field joints on fittings, such

as 3D radius elbows and

induction bends and on

projects with steep slopes.

The group’s global

customers rely on its

robotic technology to

ensure pipeline integrity

for offshore and onshore

projects around the world.

Currently, an 8 in. oil

line in the Middle East is

undergoing internal field

joint coating in a pipeline

with a 0.5 in. wall thickness.

The wall thickness required

developing new equipment

capable of navigating in very

tight spaces and our wireless

telemetry provides superior

results. C48 telemetry

allows equipment to coat

internal field joints as far as

1000 m inside the pipe while maintaining full, untethered

control.

Protecting assets in the Gulf of Arabia was

accomplished after CRTS internally cleaned, coated and

inspected 12 543 field joints on a laybarge using SP 9888

liquid coating. Protecting this vital 36 in. sour gas pipeline

in the Hasbah and Arabiyah fields required additional

special equipment, such as line-up clamp

attachments; and pipe rotators and a

safety winch were designed and built by

CRTS and transported to the offshore

site.

Coating internal field joints of

factory-coated pipe provides end-

to-end corrosion protection for all

types of pipelines including natural

gas, crude oil, potable water and

salt water. CRTS maintains strict

quality standards on all robotic

machinery and coating services

to meet and exceed customer

expectations of 100% defect-free

coating application. CRTS, Inc. is an

ISO 9001:2008 certified company

and a wholly-owned subsidiary of

Aegion, Inc.

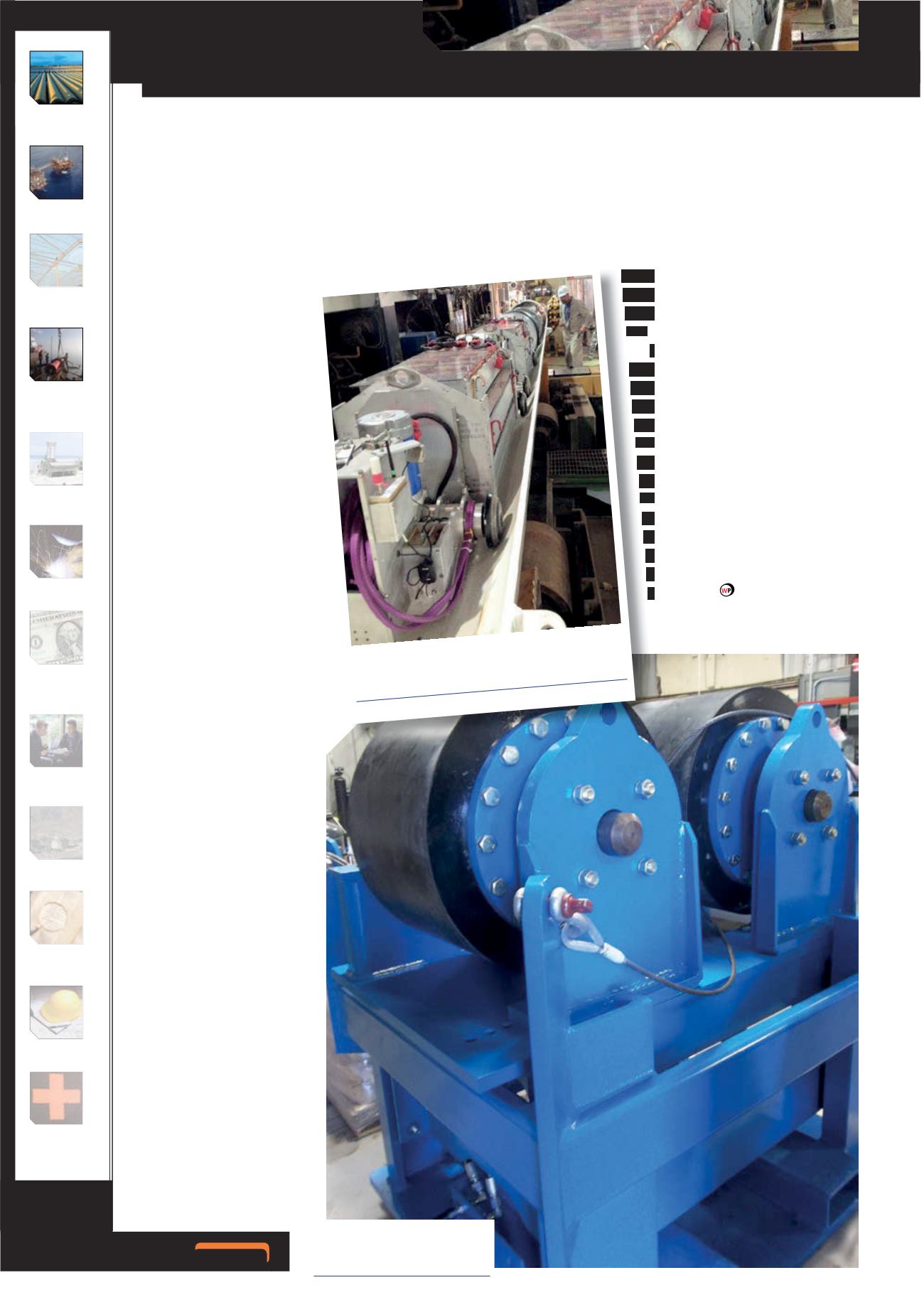

Custom-built rotators handle

immense pipes both onshore

and offshore.

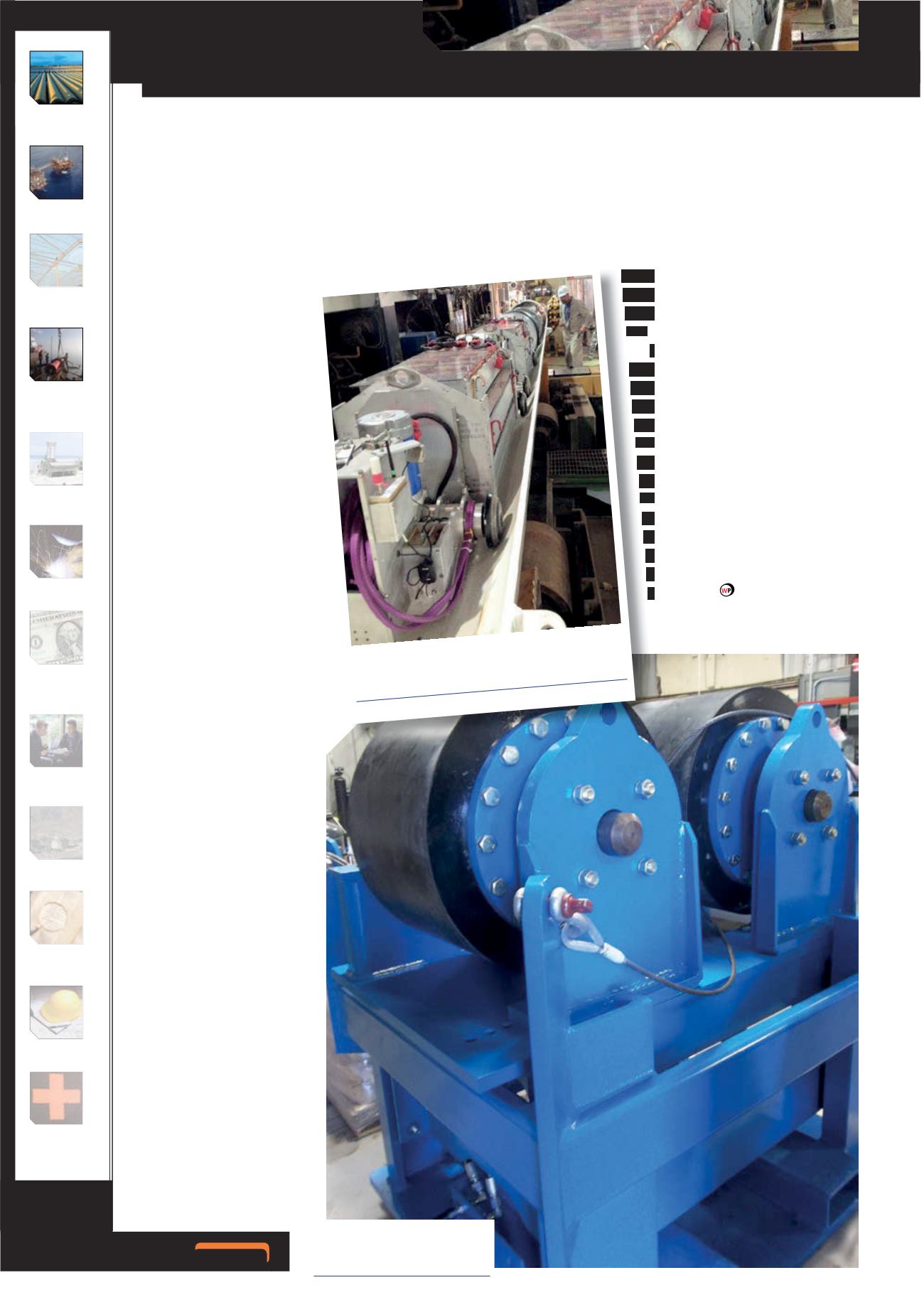

C48 telemetry allows corrosion prevention

equipment to send and receive data up to

1000 m into the pipe.