The outcomes were used by the filter

OEMs to select filter area and size, and

to derive the process air and steam

requirements to achieve the target

moisture levels.

QCAT test results

QCAT developed an internal procedure

for evaluating pressure filtration. Air

and steam testing was carried out to

examine the reduction in free moisture

relative to the applied pressure. The

testing also included a vacuum

reference test at -70 kPa. The testwork

results (Table 1) indicated:

n

Pressure filtration with air reduced

product residual moisture by 9.5%

(New Zealand metallurgical coal)

to 12.3% (New South Wales thermal

coal) absolute with respect to the

vacuum reference test moisture.

n

Supplementing the process with

high pressure steam gave residual

moistures below 10%.

OEM test results

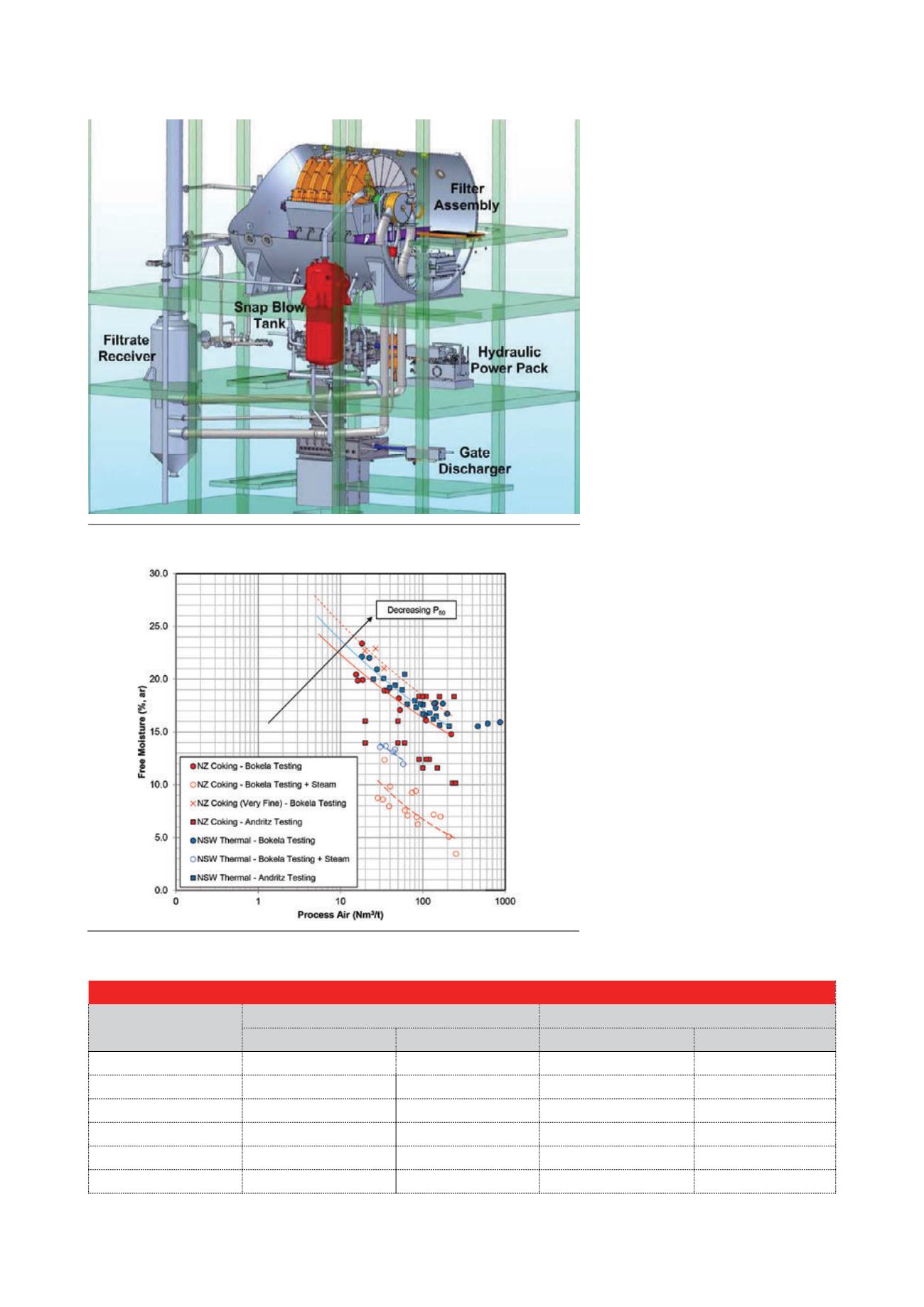

Figure 4 shows the results from the

OEM testing. The moisture outcomes

are generally independent of the testing

laboratory, with the relationships

between process air requirements and

residual product moistures being

similar.

The product surface moisture

decreases with increasing air flow

according to a power law relationship,

and there is reduced ability to target

moisture reductions below a certain

level, depending on particle size

distribution. This is in line with the plot

shown in Figure 1.

The test feed solids concentration

and flocculant addition rate do not

significantly affect the final product

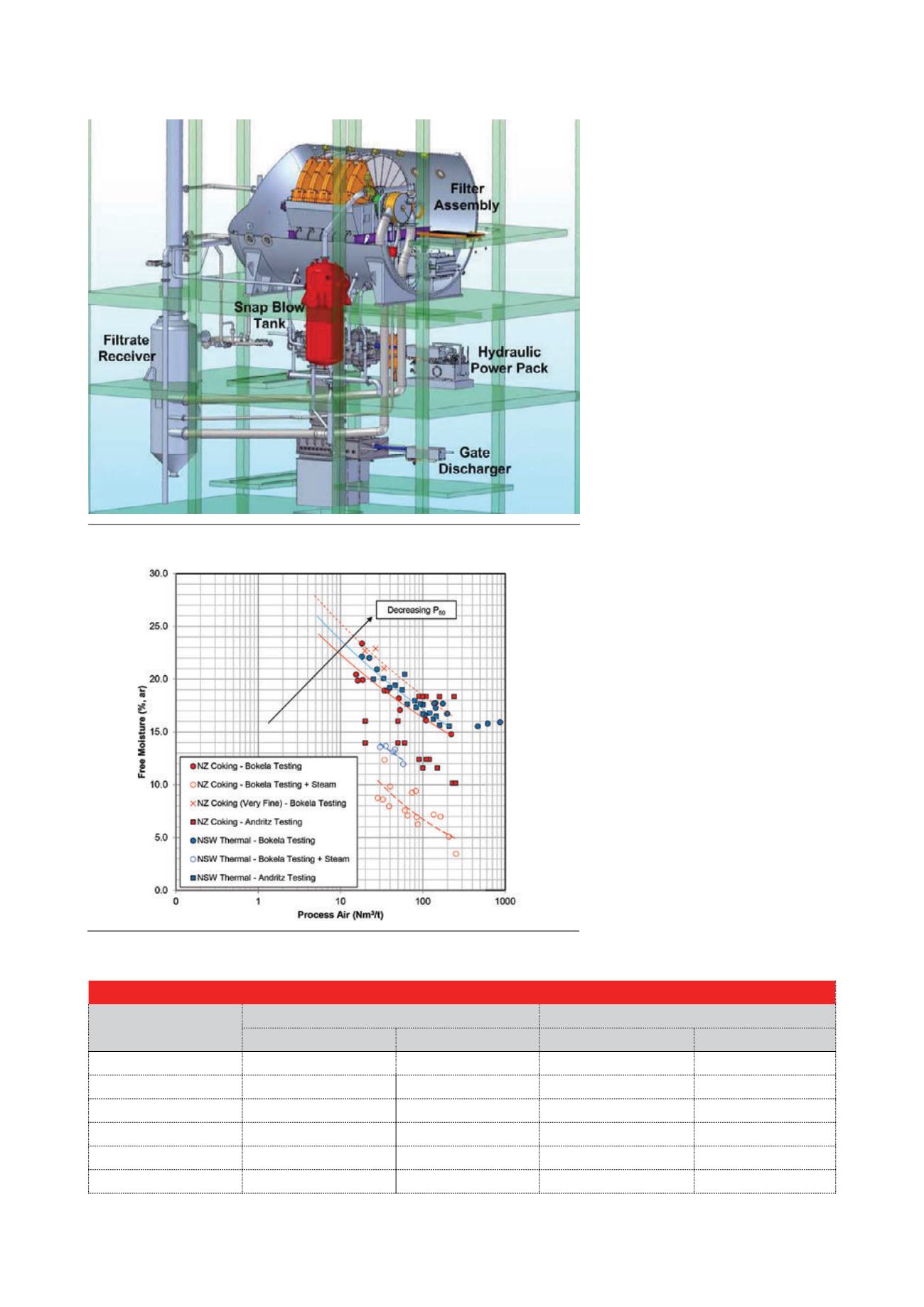

Figure 3. Sectional view Bokela hyperbaric disc filter and ancillaries.

Table 1. QCAT testing: residual moisture relative to pressure

Pressure kPa

New Zealand metallurgical coal

New South Wales thermal coal

Air only

Air + steam

Air only

Air + stream

-70

24.7

31.2

101

29.7

16.6

31.7

203

23.5

13.2

27.8

405

20.6

11.7

23.1

507

19.3

10.9

18.2

588

15.2

7.4

18.9

9.0

Figure 4. Filtercake free moisture relative to process air and steam requirements.

70

|

World Coal

|

June 2015