surface moisture; however, use of

flocculant to pre-treat the filter feed

yields increases in filter throughput.

Use of steam addition, to supplement

the filtration process, significantly

increases the filter throughput and

reduces the final product surface

moisture by between 5% and 10%

(absolute) relative to the corresponding

air only case.

The process air duty to achieve a

baseline surface moisture increases as

the filter feed particle size distribution

becomes finer. For example, with an air

usage of 50 Normal (N) m

3

/t, the

Queensland metallurgical coal with a

P

50

of 0.10 mm will achieve a surface

moisture of 15%. The considerably finer

New Zealand metallurgical coal with a

P

50

of 0.02 mm will achieve a surface

moisture of 20% with the same air

usage.

The final moisture outcomes at the

high pressure settings were consistent

with the QCAT testing results.

New Zealand metallurgical

coal study

This study was managed by Brightwater

Engineering Limited (BEL) and QCC

provided engineering services to

develop the design of the proposed new

flotation facility. The proposed upgrade

aimed to process the combined -0.2 mm

streams from the existing 320 tph (ar)

coal preparation plant (CPP). A tailings

reclaim operation would also supply

fines to the existing plant, and this was

allowed for in the design. The nominal

design capacity of the proposed flotation

facility was 96 tph (ad) of fresh feed.

The process design and plant layout

developed as part of the study included:

n

Three 70 m

3

froth flotation tank cells

in a series (cell to cell) configuration.

n

One 20 m dia. coal thickener.

n

One x 70 m

2

hyperbaric disc filter

and process air compressor.

n

Diesel-fired boiler and boiler water

feed treatment plant.

n

Ancillary services.

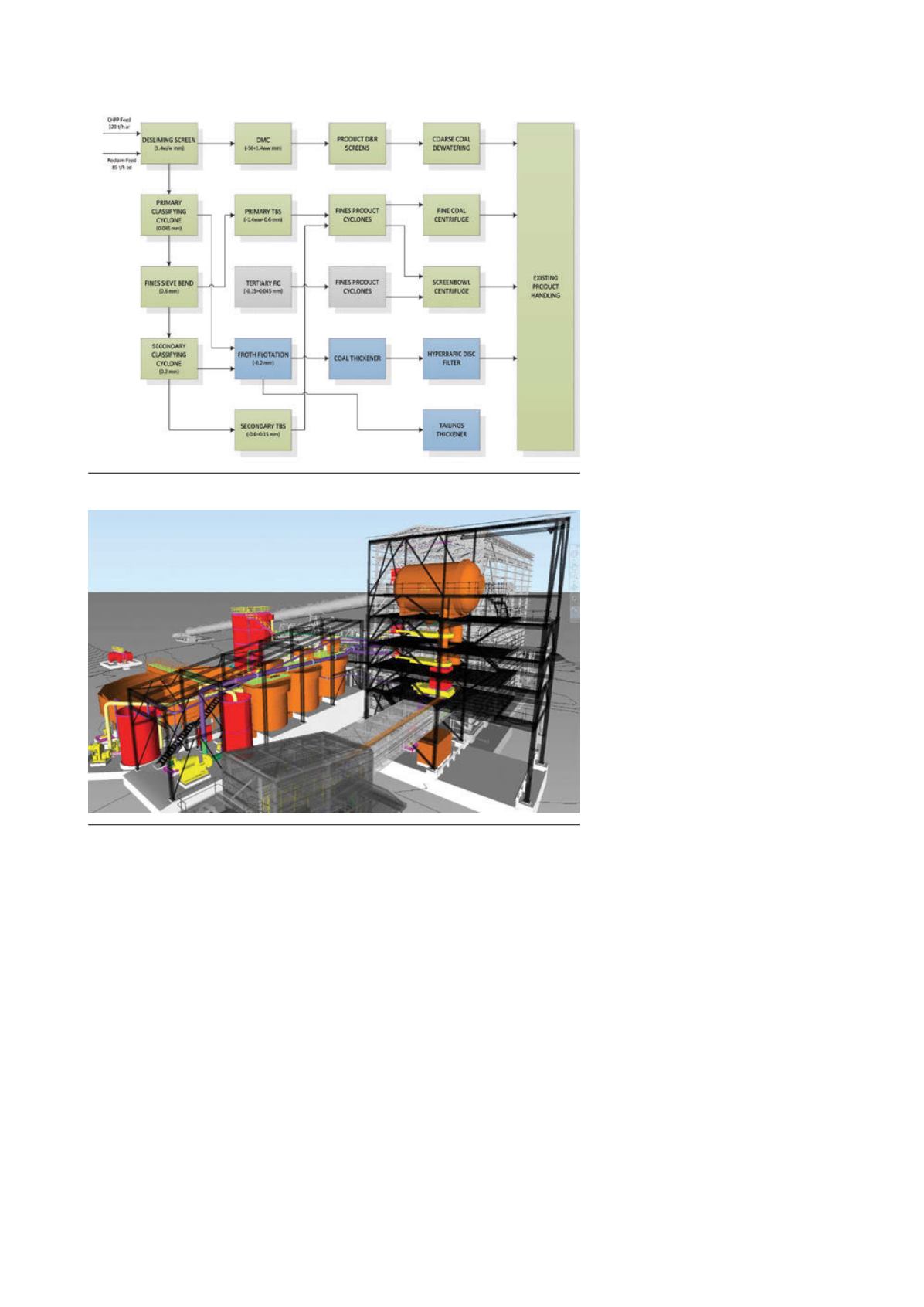

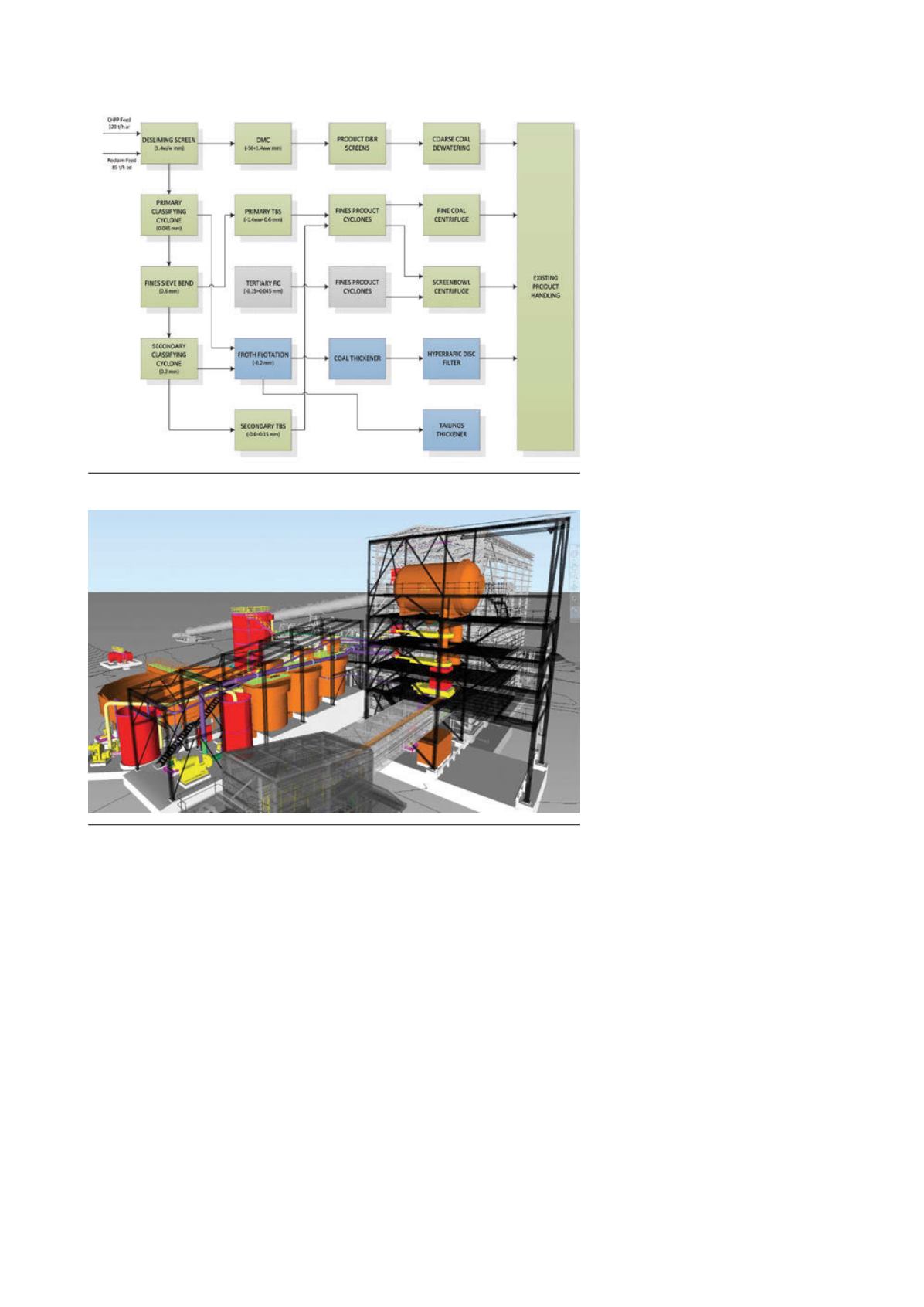

The plant process flowsheet and a 3D

Navisworks view of the proposed

facility are provided in Figures 5 and 6.

Projected plant production and yield

increases were developed for all feed

types for normal operating conditions.

For a hyperbaric filter with steam

addition, a filtercake total moisture of

approximately 10% was guaranteed by

the OEM. For the nominal design case,

this will result in a production increase

of approximately 51 tph (ad) and an

overall plant yield increase of 3.8% (ar),

and a negligible (0.1%) increase in

overall washed coal moisture.

The hyperbaric disc filter would

require 90 Nm

3

/t (or 4100 Nm

3

/hr) of

process air with a delivery pressure of

0.6 MPa and 80 kg/t of process steam, to

achieve the target filtercake total product

moisture of 10% (ar).

The estimated total operating costs

(2012 basis) for the proposed plant is

projected to be NZ$16.33 t of flotation

feed. The boiler diesel consumption

would constitute approximately 50% of

this operating cost.

This project is currently on hold due

to the poor prevailing market conditions

for hard coking coal.

New South Wales thermal

coal flotation upgrade

study

This study was managed by QCC to

develop the design of the proposed

flotation facility to feasibility level.

The proposed upgrade aimed to

process the primary classifying cyclone

overflow (-0.09 mm) and the fines

product screen underflow (-0.25 mm).

Figure 5. New Zealand metallurgical coal flotation upgrade – flowsheet.

Figure 6. New Zealand metallurgical coal flotation upgrade study.

72

|

World Coal

|

June 2015