provides a number of valuable

advantages, including higher

performance and zero overloads.

Intelligent grabbing

technology

A full grab is crucial for high turnover

in bulk handling. The aim in the

development of SmartGrip was to

further develop the bulk handling

sector. The unique feature of SmartGrip

is having recourse to data collected on

the grab closing process. For the data

collection different cranes, grabs,

materials and the performance of

diverse-skilled crane operators were

considered.

Data mining

By means of the gathered information,

a model was developed using data

mining processes through which the

filling volume of grabs can be

optimised during the work process.

Based on the gained turnover

analyses from various ports around the

world, the data showed, on average,

only 70% of the grab capacity is used.

Moreover the utilisation of the cranes is

even worse due to unsuitable grabs.

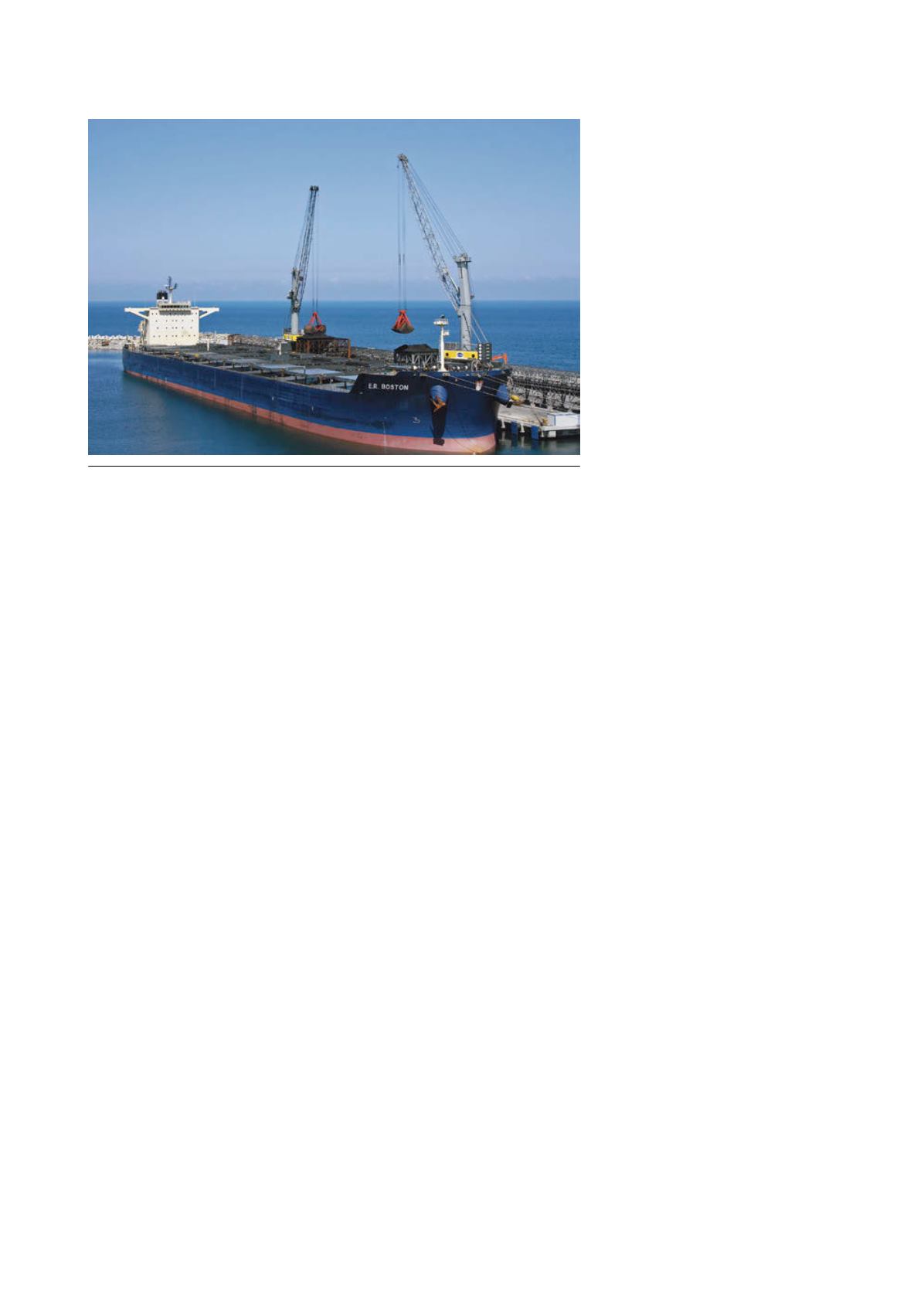

This was affirmed with a test arranged

at Eren Port in Turkey with an optimal

grab, leading to an increase in turnover

from 1200 tph to 1800 tph (+40%). Those

results made clear that the biggest

leverage for turnover is associated with

the grab and its proper filling. The

analysis also showed that even a

properly selected grab is just a

compromise for a minor set of

conditions. Those conditions are:

n

n

Different ship sizes.

n

n

Different materials.

n

n

Different material densities.

n

n

Material density changes (up to

20% per ship due to compression).

n

n

Grab geometry.

n

n

Grab hit angle.

n

n

Skills of crane driver.

Suboptimal conditions can lead to

two possible situations:

n

n

The selected grab is too small,

which entails poor turnover results.

n

n

The selected grab is too big, which

results in overloads that harm

the crane structure. Moreover

overloads are causing security

stops on the crane that are highly

time-consuming.

As a result, ports are faced with less

turnover (tph) than expected.

Mode of operation

The developed SmartGrip algorithm

learns the machine settings and material

properties autonomously. The

remarkable thing is that this is a

self-learning model: it adapts

continuously. By using various

parameters the system adapts to the

given reality and to the respective crane

operator. It will take the type of bulk

material, such as density, compression

and granularity, as well as current

conditions, such as material penetration

or type of grab, into account. The crane

requires no additional equipment like

specific sensors or cameras.

Furthermore, existing cranes can be

easily retrofitted with the appropriate

software.

Using SmartGrip, the driver controls

the closing of the grab. The system

controls the filling of the grab to the

optimum or a manually set load. This

enables optimal crane utilisation and

avoids overloads. Right from the second

load cycle, SmartGrip ensures that the

grab filling rate is above the average of

70%. Within a maximum of seven cycles,

the full capacity of the grab is utilised.

Valuable benefits

SmartGrip controls the filling of the

grab to suit the load curve of the crane.

This leads to perfect crane utilisation

without overloading, which results in

an extended lifetime of the crane,

saving fuel and time.

Moreover, when SmartGrip is

activated, the operator can completely

rely on the system for an accurate

determination of the material density

and optimal grabbing angle in a very

short time. The automatic and

optimised grab filling means less stress

for the crane operator, who can then

focus on other important issues like

safety.

In view of the average grab filling

rate of 70%, SmartGrip offers the

potential to fill the grab constantly to

the optimum. Additionally, turnover

variance is significantly reduced,

leading to more efficiency in

operation. Field studies showed that

even up to 40%, turnover increases are

realistic if the grab filling rate is below

average. Additionally, SmartGrip

partly closes the gap between

highly‑skilled and less-skilled drivers,

as some important parts of bulk

handling are automatically optimised

by the system.

Another striking feature offered by

SmartGrip is the possibility of

manually setting target loads. If a

crane operator needs to load a 40 t

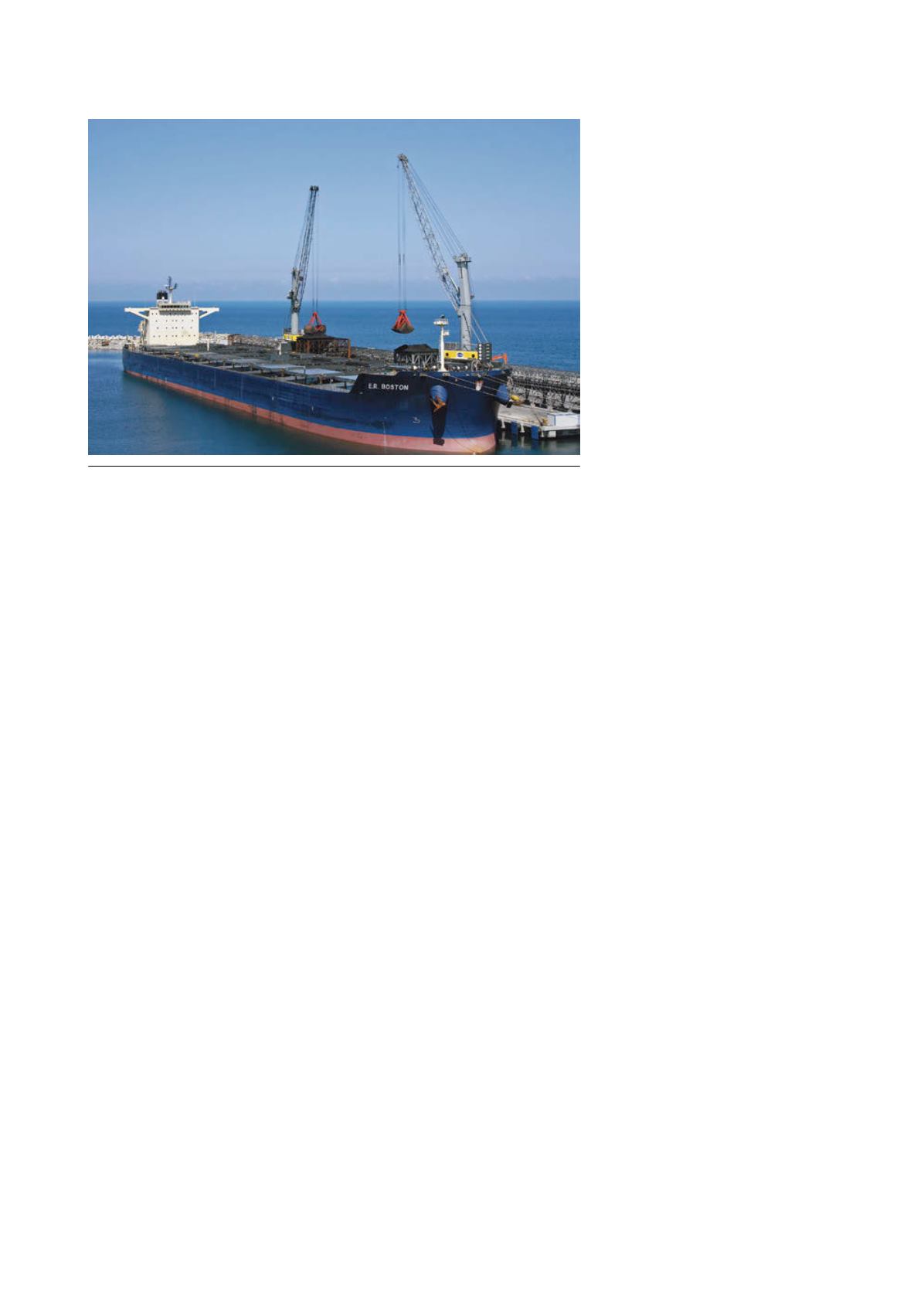

Figure 2. Unloading sticky material can lead to strong forces on the crane structure.

62

|

World Coal

|

June 2015