The nominal design capacity of the

proposed flotation facility was 236 tph

(ad) of fresh feed.

The process design and plant layout

developed as part of the feasibility

study include:

n

Two 2.4 m wide x 6.1 m long low

head single deck spirals product

dewatering screens (brownfield

addition to existing plant).

n

Four 8 m dia., 32 downcomer

Jameson Cells in a primary and

retreat duty.

n

One 18 m dia. coal thickener.

n

Two 140 m

2

hyperbaric disc filters

and the process air compressor

package.

n

Ancillary services.

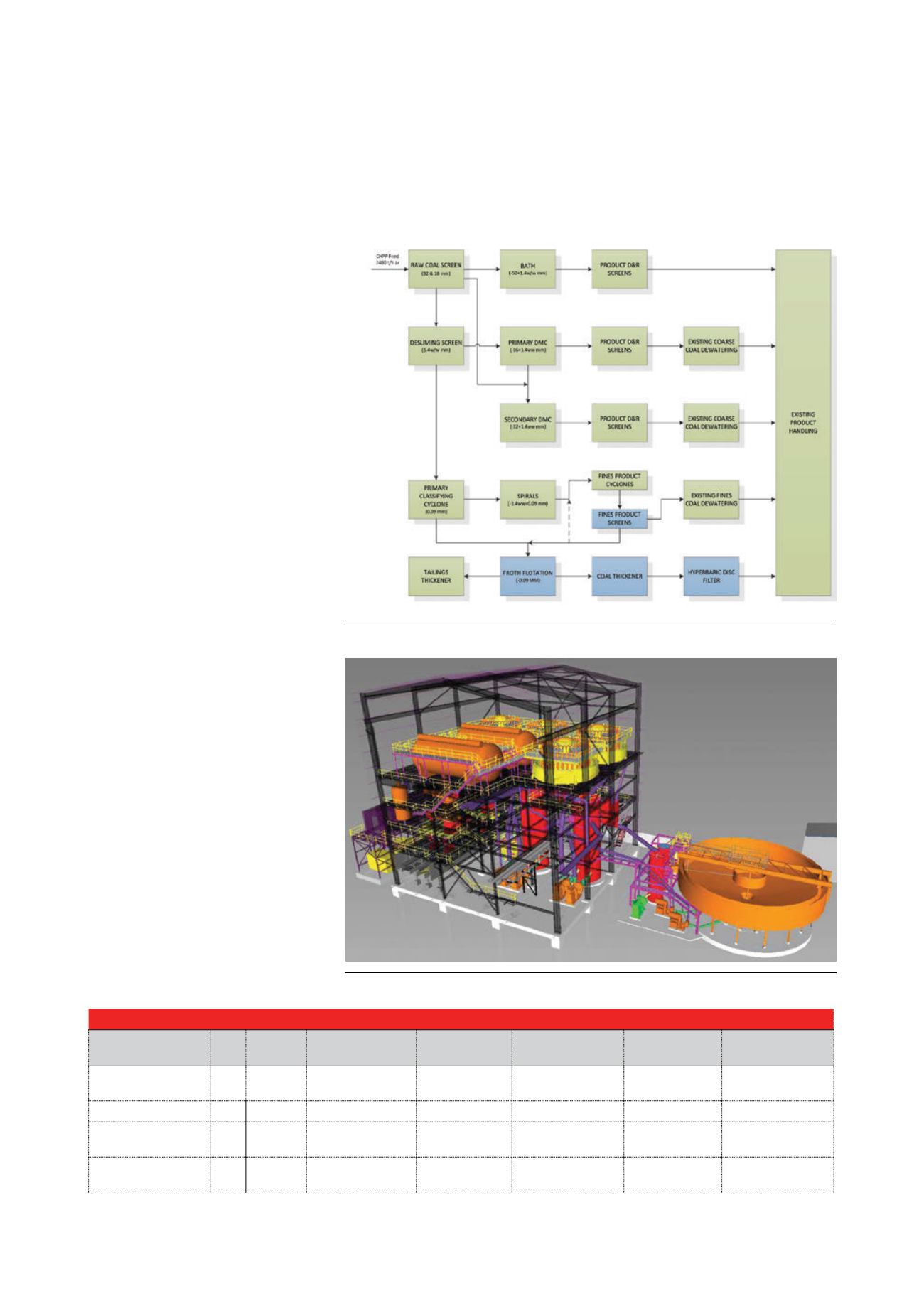

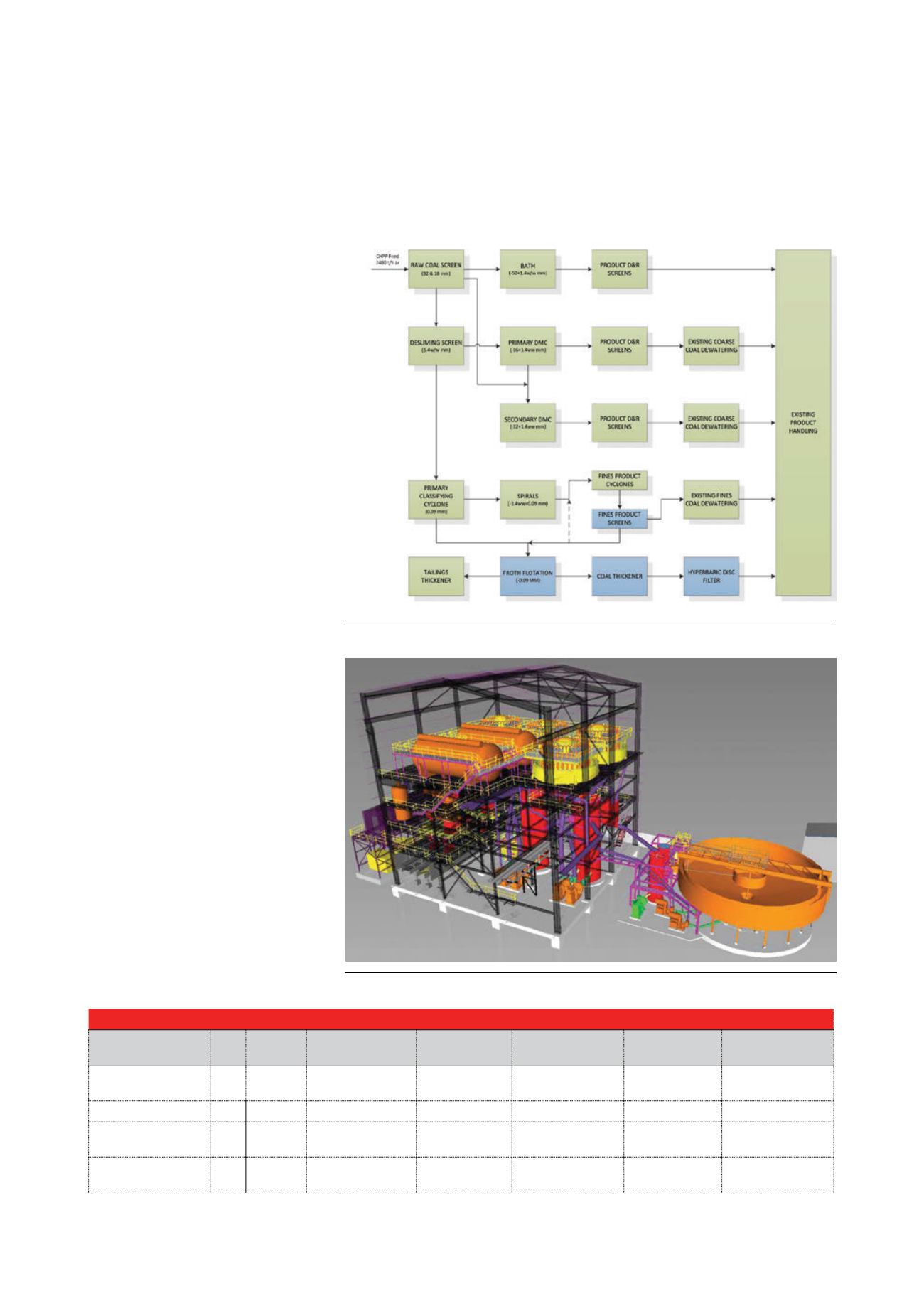

The plant process flowsheet and a 3D

Navisworks view of the proposed

facility are provided in Figures 7 and 8.

For a hyperbaric filter, a filtercake

free moisture of approximately 18%

(supported by the OEM testing) leads to

a projected 71 tph (ad) production

increase, or a plant yield increase of

3.5% (ar). Although there is a minor

increase in total CPP moisture from

9.4% to 9.8%, there is an associated

reduction in overall product ash from

13.0% down to 12.3% (ad). As such, the

gross/‘wet’ energy of the saleable

product will increase slightly.

The hyperbaric disc filter will require

140 Nm

3

/t (or 22 400 Nm

3

/hr) of

process air with a delivery pressure of

0.6 MPa to achieve the target filtercake

total product moisture of 20% (ar).

The total annual operating costs

(2013 basis) for the new plant is

projected to be AUS$5.90/t of flotation

feed. The projected operating costs in

this study is significantly less than for

the New Zealand metallurgical coal

study, given there is no requirement for

steam addition (and the associated high

operating cost of the diesel fired steam

boiler).

This project is currently on hold

due to a freeze on new capital projects

at site.

Relative costs of

dewatering technologies

The equipment costs, required drive

power and expected moisture outcomes

from a subset of the various dewatering

options considered in the studies are

Figure 7. New South Wales thermal plant upgrade – flowsheet.

Table 2. Relative capital and operating costs of dewatering technologies considered in the preliminary process selection studies

Dewatering

equipment

Qty Size

Total equipment

cost (AUS$/k)

Total installed

power (kW)

Equipment power

cost (AUS$/t)

Boiler diesel cost

(AUS$/t)

Free moisture (% ar)

Screenbowl centrifuge 3

50 tph

max

1500

950

0.38

-

26.0

Vacuum disc filter

2

176 m

2

3200

960

0.38

-

27.0

Hyperbaric disc filter

–

air only

2

140 m

2

7800

2200

0.88

-

18.0

Hyperbaric disc filter

–

air + steam

1

84 m

2

5100

1780

0.70

9.44

13.0

Figure 8. New South Wales thermal coal flotation upgrade – Navis model.

June 2015

|

World Coal

|

73