circumstances, its savings on dump

rehabilitation may result in significant

savings for Anglo’s South African coal

business and the coal mining industry.

This would be achieved either by

eliminating the need for topsoil

entirely or by significantly reducing

the quantities required to achieve the

desired rehabilitation outcome.

Lessons

Whether Fungcoal can be replicated at

different sites depends on a number of

variables. In the first place, a suitable

source of weathered coal needs to be

available within a reasonable distance

to the site. Should the distance be too

great, it is likely that conventional

rehabilitation with sub- and topsoil

would be more cost effective.

Additionally, the medium on which

the Fungcoal is intended to be applied,

whether it is coal discard or opencast

spoils, needs to be suitable. Where the

medium is acid generating, or more

precisely where the acid neutralising

capacity of the medium is insufficient,

Fungcoal will probably not succeed.

Importantly, Fungcoal needs to fit

in with the expectations of interested

and affected parties, particularly

regulators and local communities.

Where the purpose of rehabilitation is

to create a stable land form for grazing

or wilderness land use, Fungcoal is

probably suited in most instances.

Where the land has to be returned to

high‑quality arable capability,

Fungcoal on its own may not be

adequate, although it may support

improvement of the quality of

rehabilitation in terms of organic

content and decompaction of the soil.

Sharing innovation

While the technology has been

patented, Anglo American has taken a

decision not to use it to pursue

commercial value, but to improve the

quality of rehabilitation across the

mining industry for the benefit of the

natural environment and communities

that host mining sites. The company

has shared the technology and

research in various scientific and trade

publications.

In doing so, Anglo American seeks

to progress the development of

Fungcoal by gaining wider acceptance

across the sector and increasing its use,

as well as engaging with regulators

and continuing to monitor the trial

sites over time.

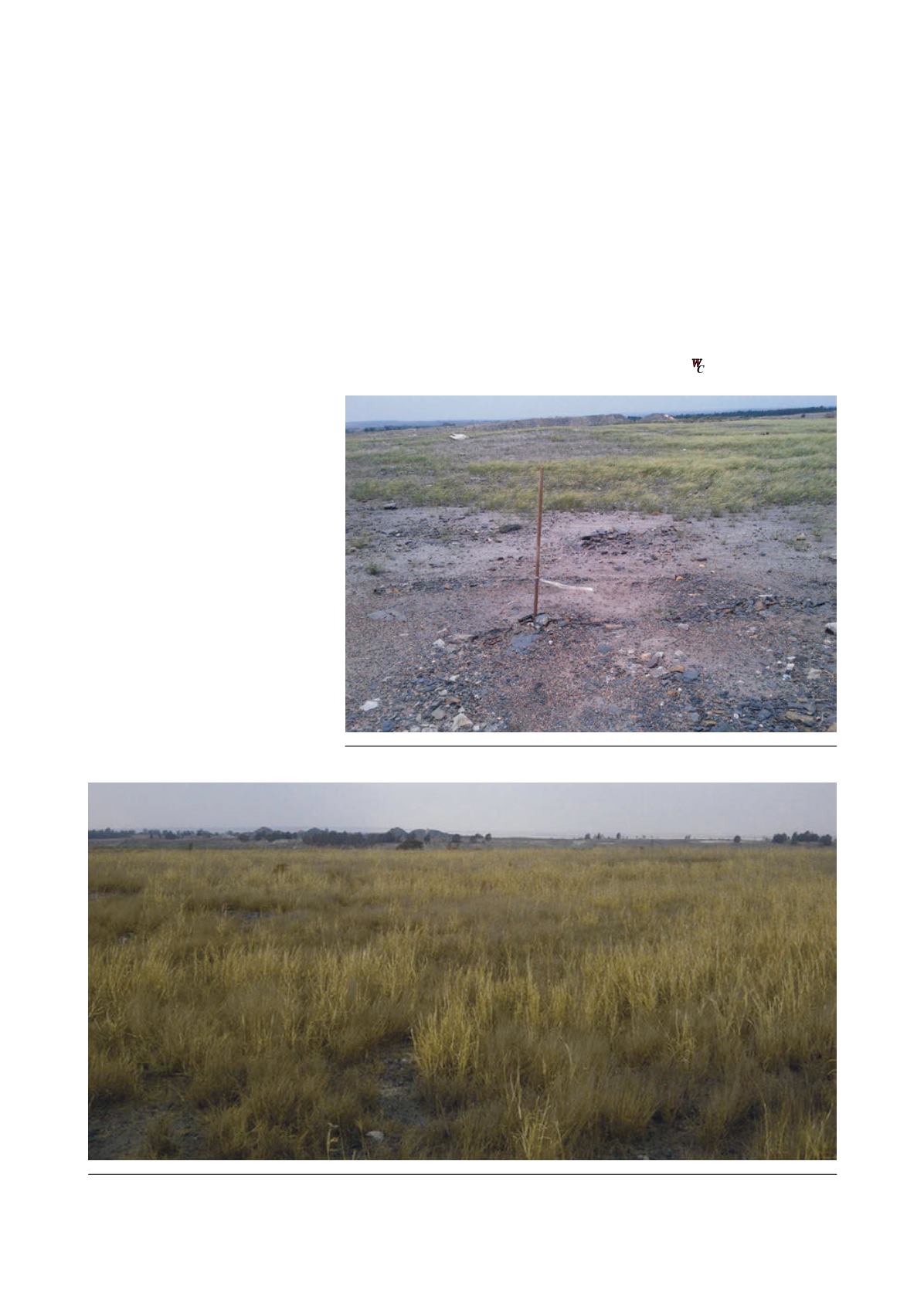

Figure 1. Kromdraai untreated.

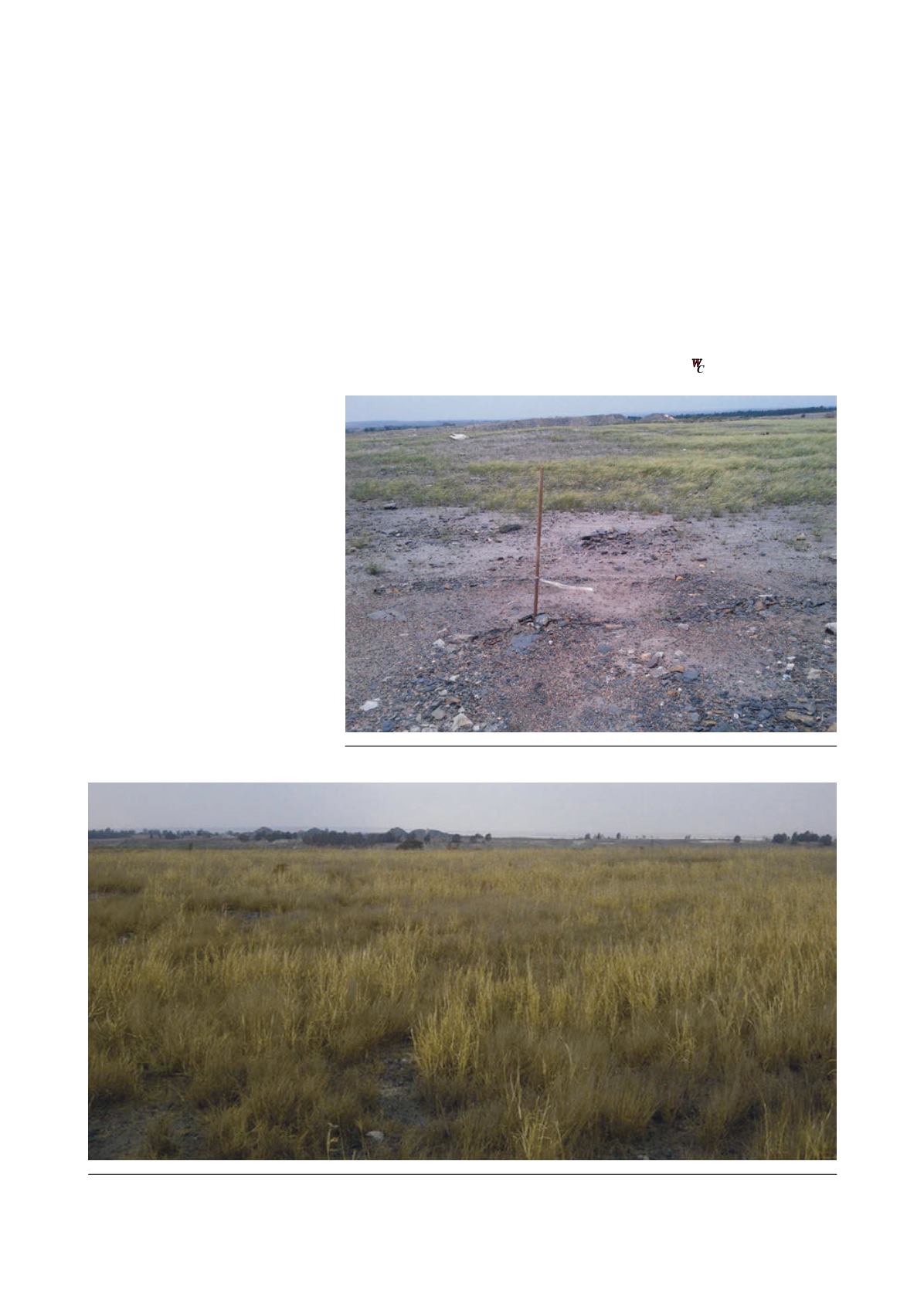

Figure 2. Kromdraai treated.

August 2015

|

World Coal

|

101