14 |

Oilfield Technology

May

2015

exploration companies with a challenge in the future. So the

question here is not just one of cost – are operators going

to be able to explore efficiently in these more challenging

arenas with the technology available now, and if new ways

be found to explore these remote areas in a cost-effective,

environmentally sensitive way.

So how can the industry gain, rather than suffer from this

downturn? Are there technologies available that produce the

required results at less cost, enabling operators to continue

to explore, produce and be innovative, yet at a cost low

enough to maintain the exploration programmes?

The straight answer is ‘Yes’, and in fact, these

technologies have been around for a while, and now is the

time to look at these as a way forward.

Still the most accurate and thorough way of looking at

the subsurface is to use seismic – and it is true to say that

in the field of seismic acquisition, there have been leaps

and bounds in recent years, with 3D now very common

and 4D becoming more popular, not to mention the myriad

of specialist acquisition techniques, configurations and

processing tools. Seismic acquisition, particularly 3D, is one

of the major costs associated with exploration, and is an

obvious target for cost cutting. However, cutting acquisition

costs seems illogical as doing so either stops a programme

dead, or increases the risk of failure. For oil companies, the

only way to keep exploration on the agenda is to find a way

to reduce costs at all stages of the lifecycle, while continuing

to reduce drilling risk.

The ‘Holy Grail’ of exploration would be the one piece of

technology that identifies hydrocarbon deposits, providing

an ‘x marks the spot’ on a map. This technology does not

exist, but the industry has the next best thing: combinations

of datasets providing different ‘views’ based on the different

properties of subsurface structures, providing the greatest

likelihood of hydrocarbon presence through imaging

subsurface structure. Exploration is rarely dependent on

a single source of information, so having good constraint

on data, in a timely and effective manner, is the key to

successful well planning. For this reason Full Tensor Gravity

Gradiometry has been adopted by dozens of established

exploration companies globally, used in conjunction with

other geophysical techniques available.

The use of this complementary technology reduces costs,

speeds up workflow and increases confidence by screening

promising targets in a block before taking on a more detailed,

expensive seismic acquisition programme.

FTG – full tensor gravity – is a technology recognised

as a critical step in all stages of the exploration workflow.

Essentially it is a non-seismic geophysical technique which

is quicker, easier, more adaptable, non-invasive and cheaper

to acquire, process and interpret than seismic, and in a

very short time can identify promising targets for further

investigation, at which stage a 2D or 3D seismic programme

can be designed over a smaller, more focussed area.

Sowhat isFTG?Andhowdoes itwork?

Gravity gradiometry is “the study and measurement of

variations in acceleration due to gravity”.

1

It is used to

measure the density variations of the subsurface; effectively

the rate of change of rock properties. From this information

it is possible to build a picture of subsurface anomalies

which can then be used to more accurately target oil, gas

and mineral deposits. Full tensor gradiometers measure the

rate of change of the gravity vector in all three perpendicular

directions giving rise to a gravity gradient tensor.

Gravitygradiometers

There are two types of gravity gradiometers currently in

operation, but crucially only one version (the Lockheed

Martin FTG System) directly measures all components

of gravity. This distinct technical advantage allows the

operator to benefit from quality control processes unique

to this instrument and ensures data quality and speed to

the processing and interpretation efforts; essentially only

measured components can be used in the patented and

proprietary processes used by Bell Geospace.

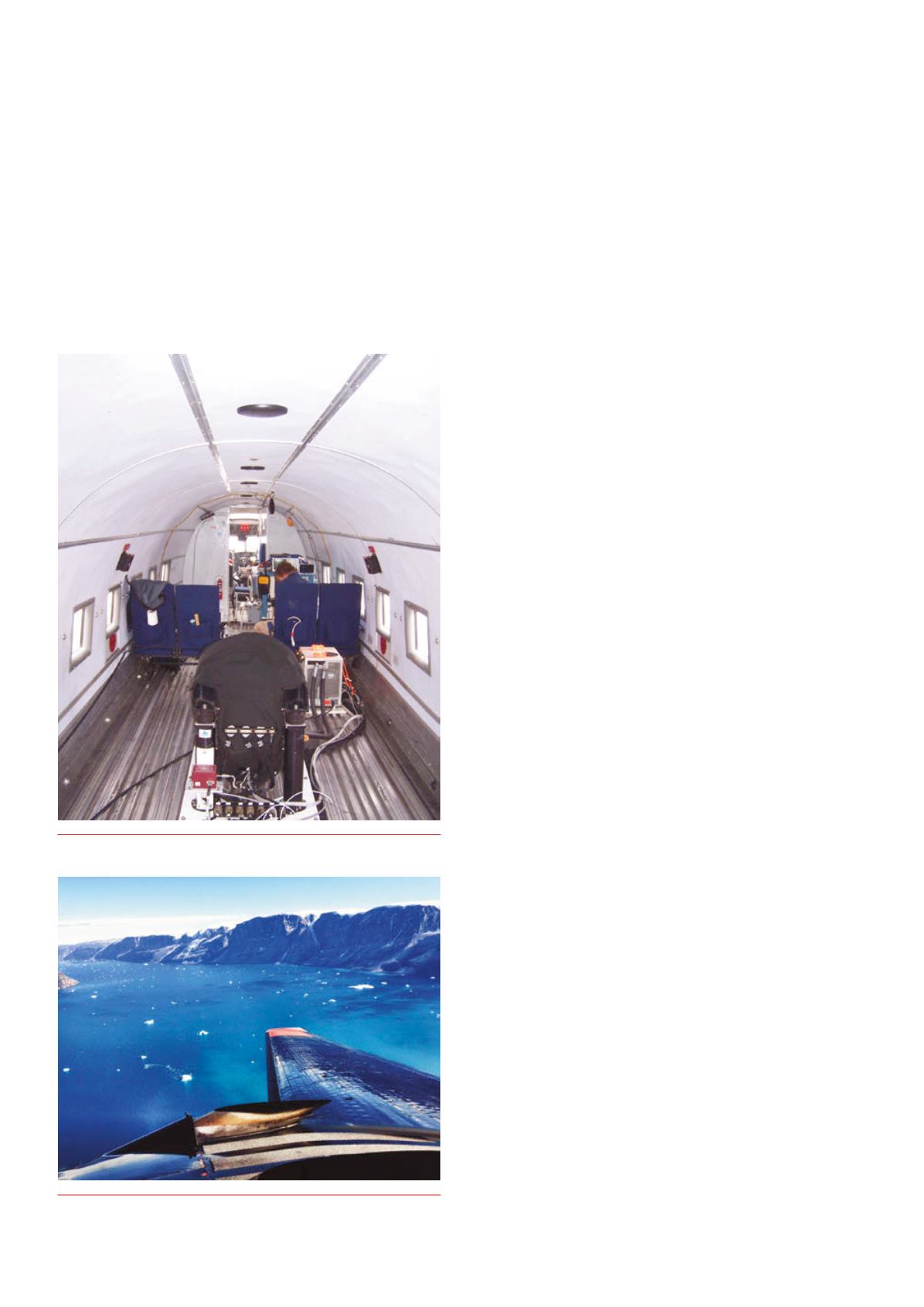

Figure 1.

FTGmounted inBasler Turbo 67.

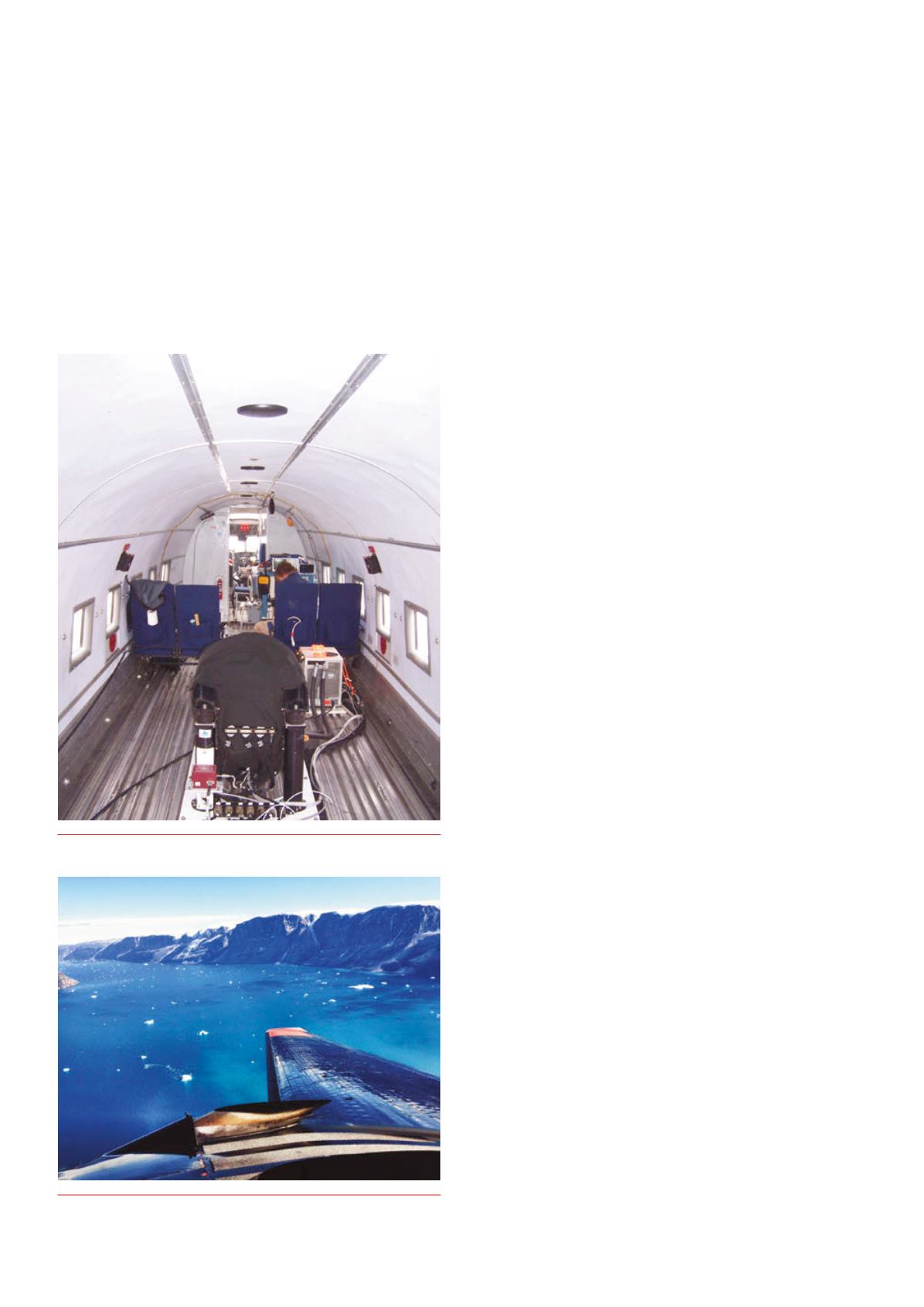

Figure 2.

Basler Turbo 67 on survey inNorthWest Greenland.