Managing the science of production

An operation that processes hundreds of thousands of barrels

a day into commercial products does not stop on a dime.

Delays are costly on a scale few can imagine. That is why data,

generated from samples far and wide – at wellheads, within

pipelines and during processes, is so important that it truly

functions as operational lifeblood. The flow of data related

to product quality, environmental compliance, worker safety

and equipment is constant, rapid and invaluable. The appetite

for data to make decisions is voracious, and an operation

like Pearl GTL would likely grind to a halt were it not for

sophisticated systems to collect, manage and report on what

is happening in real-time across the enterprise.

Managing the data pipeline with software

If data is the lifeblood of a massive GTL facility such as Pearl, a

laboratory information management system (LIMS) is its heart.

At a simplistic level, massive amounts of unrefined product are

piped into Pearl GTL, processed and then piped back out for

distribution. Only a highly sophisticated software solution is

capable of managing the data generated.

While the data pipeline includes actual data from

pipelines, generated by inline process analysers for example,

it also includes samples taken from wellheads, equipment

calibration readings and environmental analyses, among

other sources. And data arrive at the lab from these sources

unrelentingly, not to mention actual samples that require more

complex sample techniques that trained lab personnel must

perform.

Many standards and guidelines established to ensure

the consistency and quality of results guide labs like those

connected to Pearl GTL. Standards such as ISO 17025, an

international benchmark for running a testing laboratory,

codify important criteria for lab suppliers, training, record-

keeping, equipment calibration and much more. While

many know ISO 17025 for its onerous requirements and

potentially time-consuming audits, the guidelines are much

more, establishing a discipline and rigour to ensure that

data collection, synthesis and reporting is more than just a

compliance exercise – it is a way to keep a business running

efficient and profitably.

Built for complexity: SampleManager LIMS

Pearl GTL is a highly integrated project that spans harvesting

from an offshore gas fields to delivery of finished commercial

products. Not only did Shell require a solution designed for

the rigors of gas extraction and production, it also needed a

solution that integrated with other enterprise management

systems including sophisticated batch tracking solutions and

ERP systems. If these systems cannot communicate seamlessly

– sharing data and consolidating reporting – decision-making

is delayed, information is suspect and production efficiency,

quality and throughput is jeopardised.

Thermo Scientific SampleManager LIMS is designed for

state-of-the-art testing laboratories, from offshore sampling

in remote locations and onshore facilities to the pipelines

that connect them and, ultimately, bring product to market.

From accelerated sample turnaround times to centralised

access to data and operational efficiencies, the proven

benefits of SampleManager LIMS are well-known, but for

operations the scale of Pearl GTL, the system is much more: it

is a system of record for quality, compliance and engineering

excellence.

Figure 2.

Lab photos.

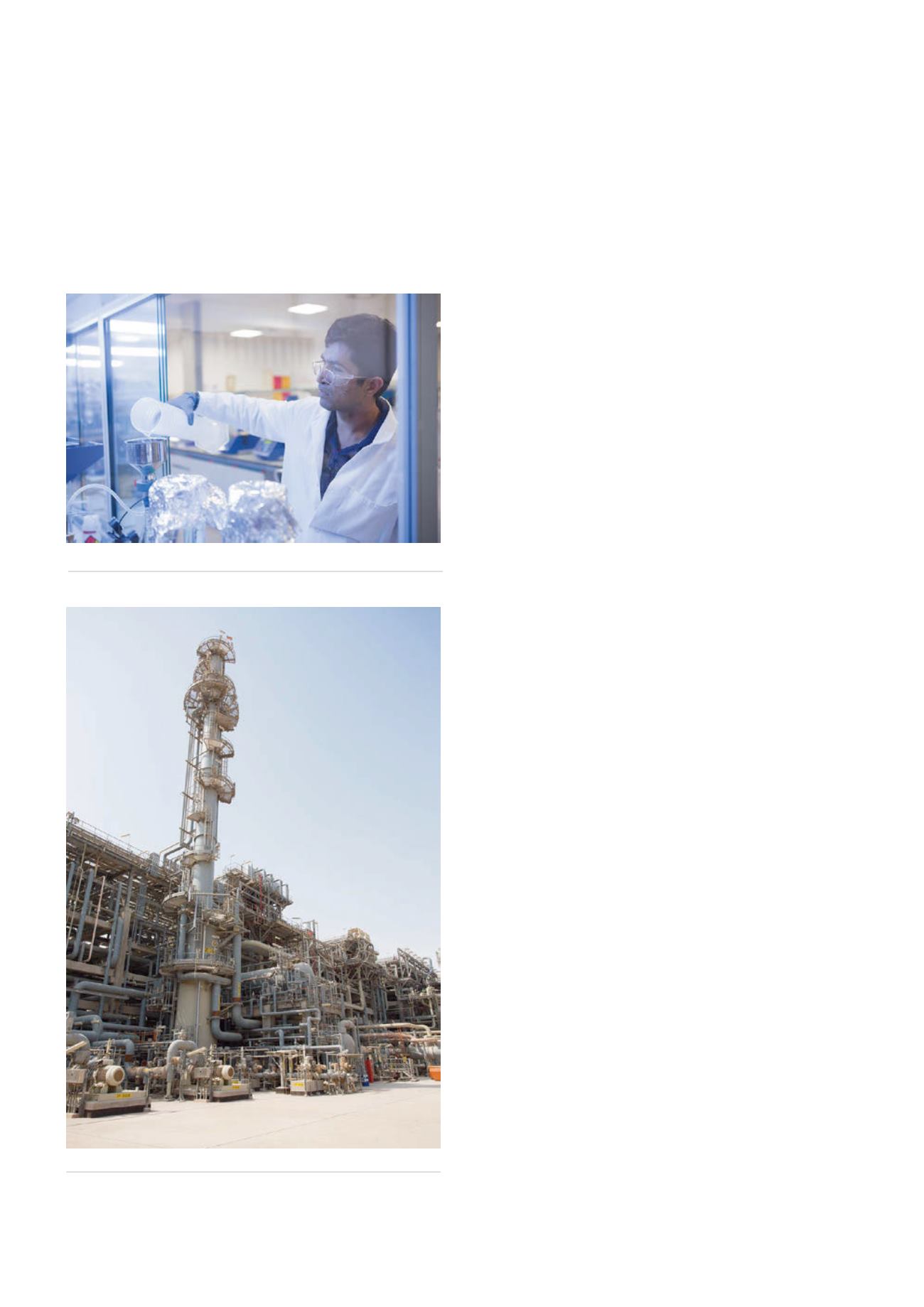

Figure 2.

GTL LES Column at Pearl GTL in Qatar.

56

World Pipelines

/

JULY 2015