The first is that it can be used to further enhance the

bandwidth efficiencies. For instance, Experion SCADA enables

users to configure multiple displays for pieces or equipment

or instruments. Users might therefore configure a standard

display showing only minimal information, but also a more

comprehensive maintenance display for when a common

fault alarm for that instrument is received from the RTU

(as described earlier). This can be configured to request all

the data needed by the pipeline controller to evaluate the

problem, but only when the display is running. When it is

closed, the SCADA system ceases to request the information,

once again ensuring efficient use of the bandwidth.

The other key benefit is realised

during configuration. Pipeline SCADA

systems must not only manage large

complex systems, but also manage

changes and additions over the

lifecycle of the asset.

Again there are already benefits

in terms of remote connections

from having a HART-equipped RTU,

which, combined with the Field

Device Manager asset management

system, allows remote configuration.

However, it is the use of templates

that dramatically reduces the burden

of configuration, cutting up-font

configuration design by up to 80% and

the time taken to add new equipment

from hours to minutes.

This is done through templates

prepared for each type of equipment

with all relevant SCADA configuration

information – all the points,

calculations, display elements, trend

definitions, relationships (such as what

is upstream and downstream), key

parameters, operations task-based

filters, and the SCADA communication

settings for the RTU or PLC. As new

equipment or instruments are added,

instead of building each point by

point and display by display, only

the few details specific to that new

addition need to added to the relevant

template. All settings common to

the equipment type are pre-filled.

Moreover, the rules-based and auto-

generating approach means new

devices will automatically be included

in relevant dashboard displays.

Finally, the approach allows for

the continual improvement controllers

aim for: as best practices evolve, the

task filters in the template just need

updating to embed it. Time spent

building points and displays is therefore

directed instead to building up the knowledge base that

informs the operation.

References

1.

Industrial Internet Insights for 2015, Accenture/GE, October 2014.

-

Internet-Changing-Competitive-Landscape-Industries.pdf

2.

Big Data analytics in oil and gas, Bain & Company, March 2014.

_

gas.pdf

3.

Unleashing Productivity: The Digital Oil Field Advantage, Booz & Co, Summer

2008.

.

pdf

4.

The rise of the midstream: Shale reinvigorates midstream growth, Deloitte Center

for Energy Solutions, November 2013.

/

Deloitte/us/Documents/energy-resources/us-er-the-rise-of-the-midstream.pdf

+1-918-259-3050 |

| vacuworx.com

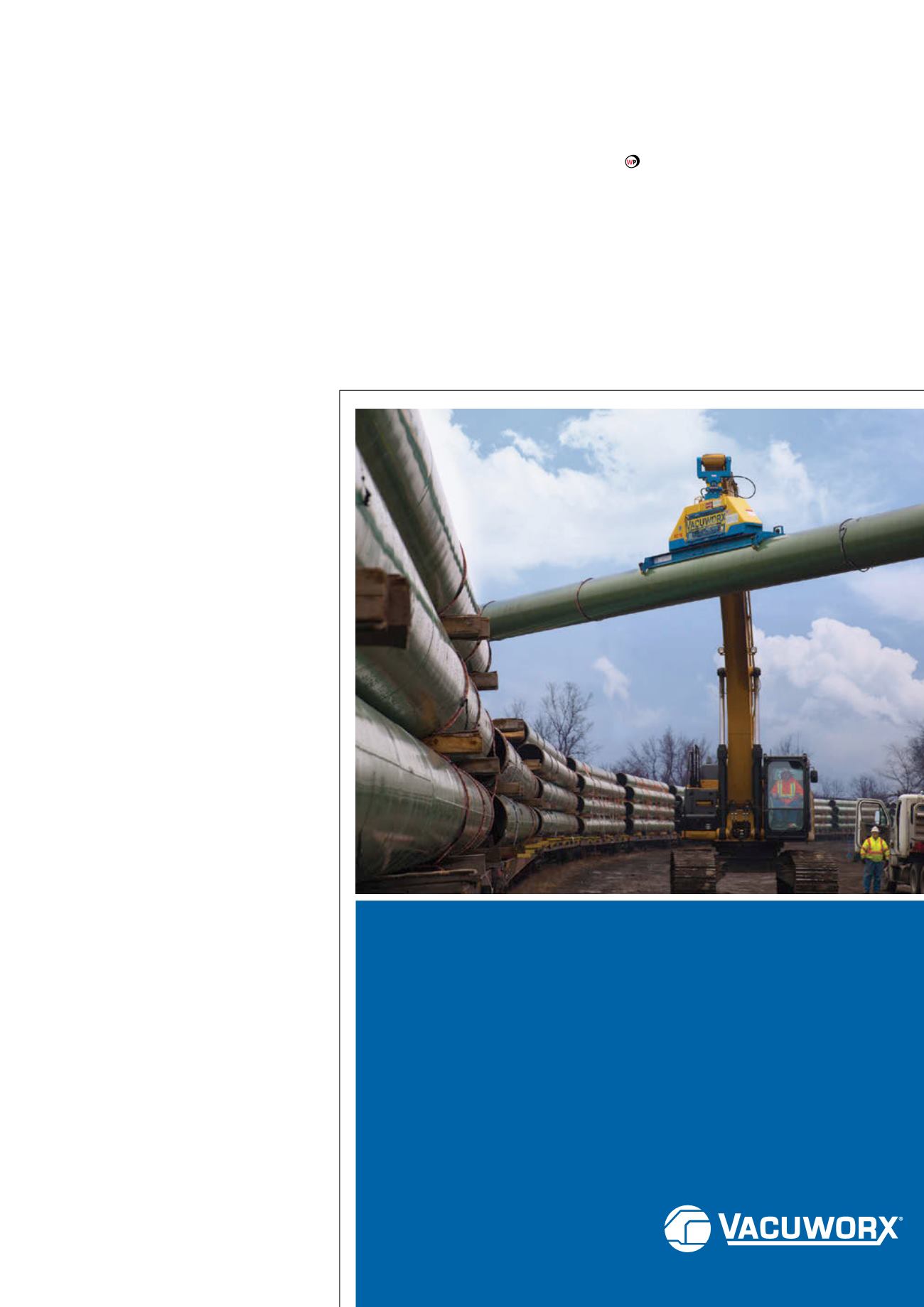

Lift materials faster, safer, smarter with Vacuworx Lifting Systems.

For over 15 years Vacuworx has been manufacturing the safest, most economical lifting

equipment for heavy-duty pipe, plate, slab, concrete barriers, and HDD drill stem.

• Faster load and unload cycles means less downtime for your workers.

• Wireless remote operation is safer than hooks, slings, or chains.

• Full inventory available for immediate purchase or rental.

• Parts, service, and technical support available 24/7 365 days a year.

Visit vacuworx.com or contact

Vacuworx for information.

TEN TIMES

more pipe.

HALF

the man hours.