Coatings

&

salts, must be removed using pretreatment before abrasive

blast cleaning to ensure long-term coating performance.

What role does Quality Control have?

What about testing and validation?

Quality control (QC) is very important from raw material

(RM) investigation through to testing finished product

after manufacturing to validating FBE coating quality

following application at the pipe coating plant. It

represents the most basic level of quality, but is still

fundamental to success. Quality assurance (QA) is the next

level and the objective of a QA programme is to prevent

product non-conformities. Here QC is still positioned

at the core to control powder or liquid coating quality,

but QA may extend to training programmes, document

control and factory audits. At the highest level, a Quality

Management system is adopted such as ISO 9001, which

Jotun has implemented at many of its factories around the

world.

Thorough understanding of the international standards

and test protocols associated with the standards as well

as the pipeline industry itself, the client’s interpretation

of these requirements and diligence to maintain standards

throughout the process are all critical factors to ensure

pipe coating success.

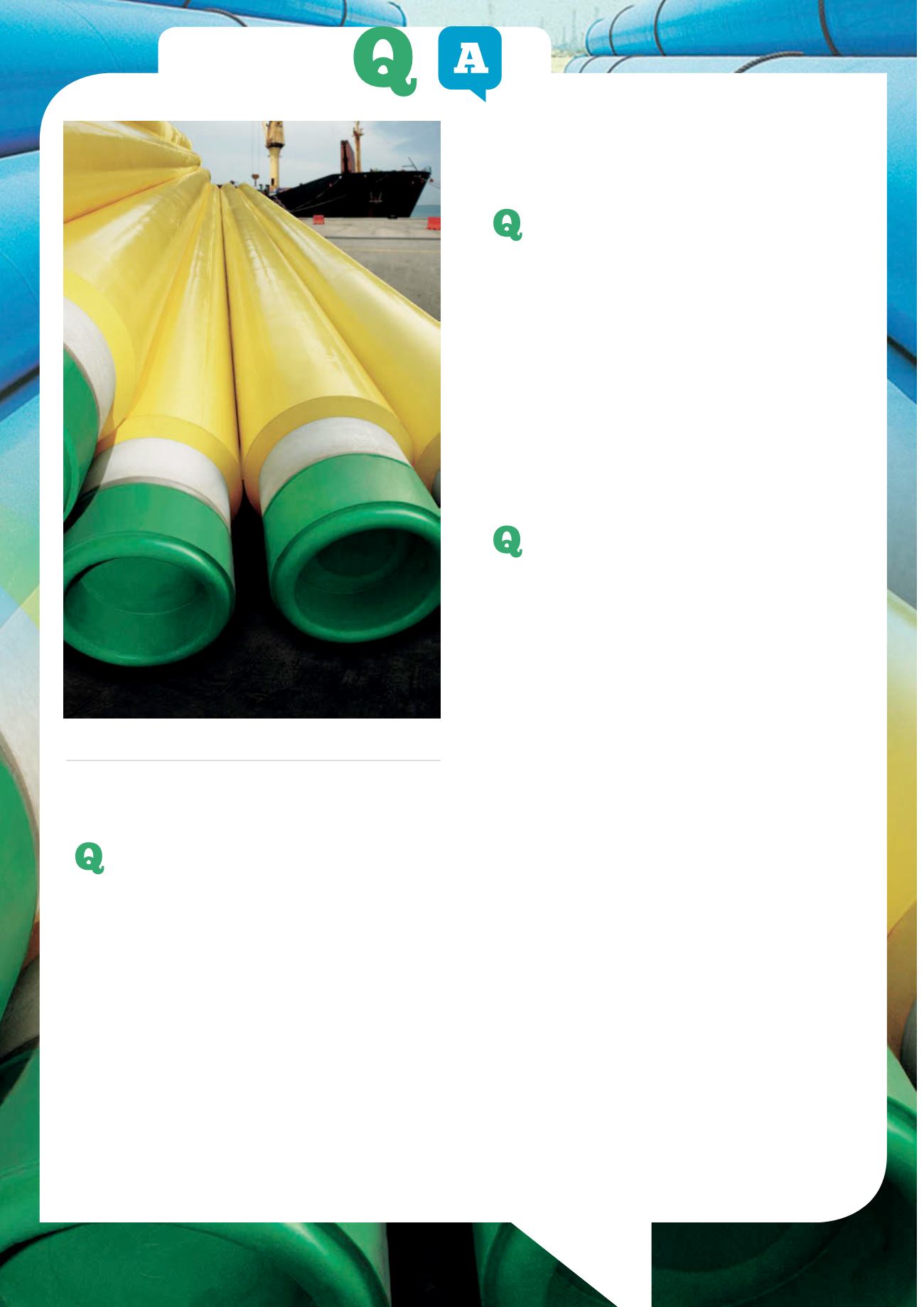

Why do we insulate pipelines?

Pipelines are insulated in order to maintain product

temperature and improve transportation of pipeline media.

In deepwater, low temperatures will be experienced,

which can lead to formation of waxes and hydrates. These

deposits can block filters and ultimately the pipeline.

Through the application of a multi-layer insulation coating

system to the external surface of the pipe, which will be

laid and then operate at depths of 2000 - 3000 m for

example, temperatures can be maintained that will prevent

such deposition.

Jotun manufactures a product called Jotapipe HT

2004, which has been used as the anti-corrosion coating

in a multi-layer insulated system in such hostile subsea

environments since 1997, performing at operating

temperatures of above 150°C (302°F).

Are you developing environmentally-

sound coatings?

Every time Jotun products are used, customers can rest

assured that they are helping to work towards a greener,

more sustainable future. Protection is at the core of all

that Jotun does. As a company, Jotun takes steps to better

protect property and of course the pipeline asset, but it

also takes steps to better protect the environment. These

efforts are consolidated under the Jotun GreenSteps

programme; a roadmap to a sustainable world and

better future. The initiative consists of five key goals,

each ensuring Jotun products are created in a way that

minimises the impact on the environment. The five Jotun

GreenSteps are: (1) reducing VOC emissions, (2) reducing

hazardous materials, (3) reducing energy consumption, (4)

reducing waste and (5) reducing carbon footprint.

Being environmentally-friendly, powder coatings do

not contain solvents, so no volatile organic compounds

(VOCs) are released into the air. Over sprayed powder can

be recycled with minimal wastage and disposal is easy and

safe. In addition, all FBE coatings made by Jotun are lead-

free. There is a growing trend for liquid coatings to have

higher volume solids and therefore lower VOC content as

well as be less harmful to operatives and the environment.

As an industry leader, Jotun makes a commitment to

the environment in all senses of the word by ensuring

its manufacturing and other operational procedures are

compliant with ISO 14001 environmental management and

OHSAS 18001 occupational health and safety management

systems.

As regards liquid coatings, the very long-term objective

would be for water-based materials thus eliminating

VOCs. Technology does exist that could be used, but the

cost at this juncture in time is unquestionably prohibitive

for most customers. Given this fact, very high solids or

Figure 2.

Insulated offshore pipe coating system using

Jotapipe HT 2004 (Photo courtesy of Bredero Shaw).

52