full-service welding solutions to contractors and end users

by bringing together the latest in available technology and

making it available to the welding industry at competitive

prices.

Dyna Torque can provide equipment, personnel and

expertise for all its customers’ pipe welding projects.

The company provides professional assistance and

expertise for solving welding problems with highly trained

personnel and quality equipment, ensuring satisfactory

production results. Dyna Torque works with its customers

from start to finish, fulfilling the requirements needed

to successfully complete pipe welding projects. Welding

services by Dyna Torque include welding procedure

development and qualification, welder training and

qualification and welding project planning, management

and execution.

In the field of welder training and qualifications, Dyna

Torque offers professional assistance and expertise for

solving welding problems with highly trained personnel

and quality equipment. At its facility in Houston, the

company offers welder training and qualification service

for procedure development and qualification, and also

offers these services on project sites, depending on the

needs of the client. The company’s automated welding

systems help to reduce training times and costs for

clients.

The LoneStar welding system

In 2000, Dyna Torque introduced the LoneStar

automatic welding system to the market. The LoneStar

is an advanced orbital automated pipe welding system

designed to modernise traditional welding techniques

and processes by integrating the latest in software

development and microprocessor technologies combined

with innovative device design to offer a compelling digital

welding solution.

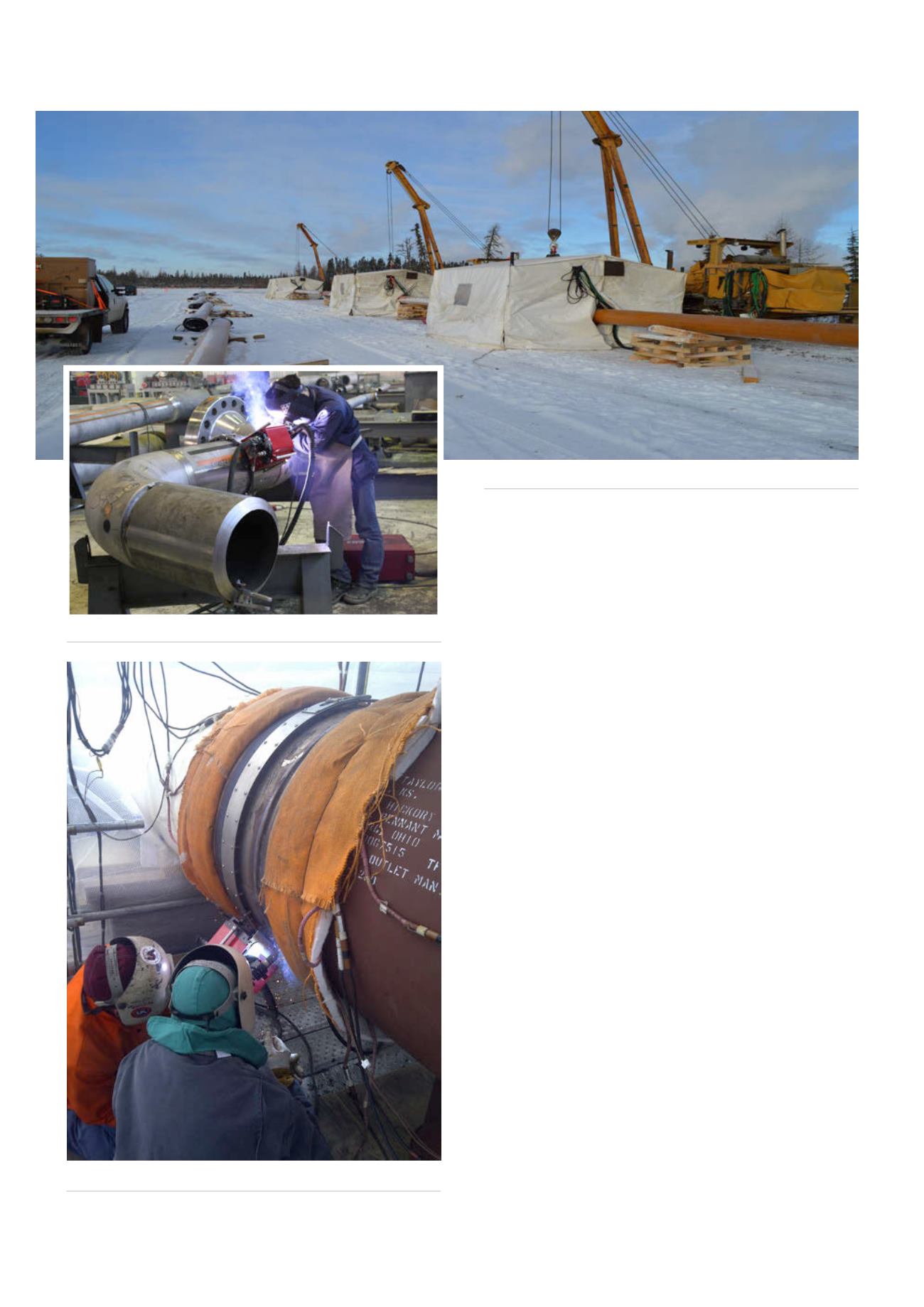

Figure 2.

Cenovus welding spread in Canada.

Figure 3.

Spool fabrication.

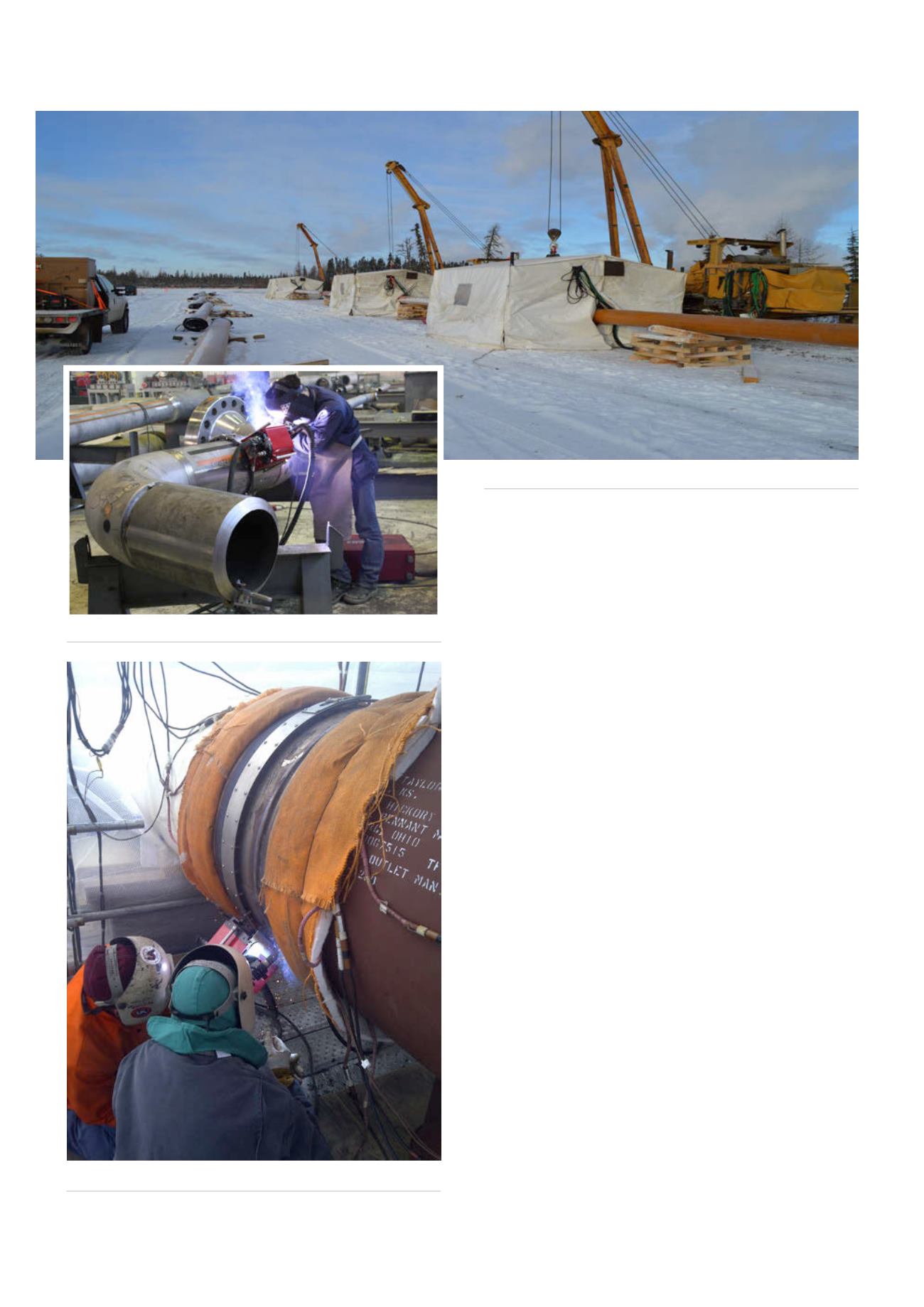

Figure 4.

Slug Catcher Welding.

66

World Pipelines

/

JULY 2015