4 in. OD up to 30 in. OD. The unit is designed such that a

single unit is capable of heating a range of different pipe

diameters.

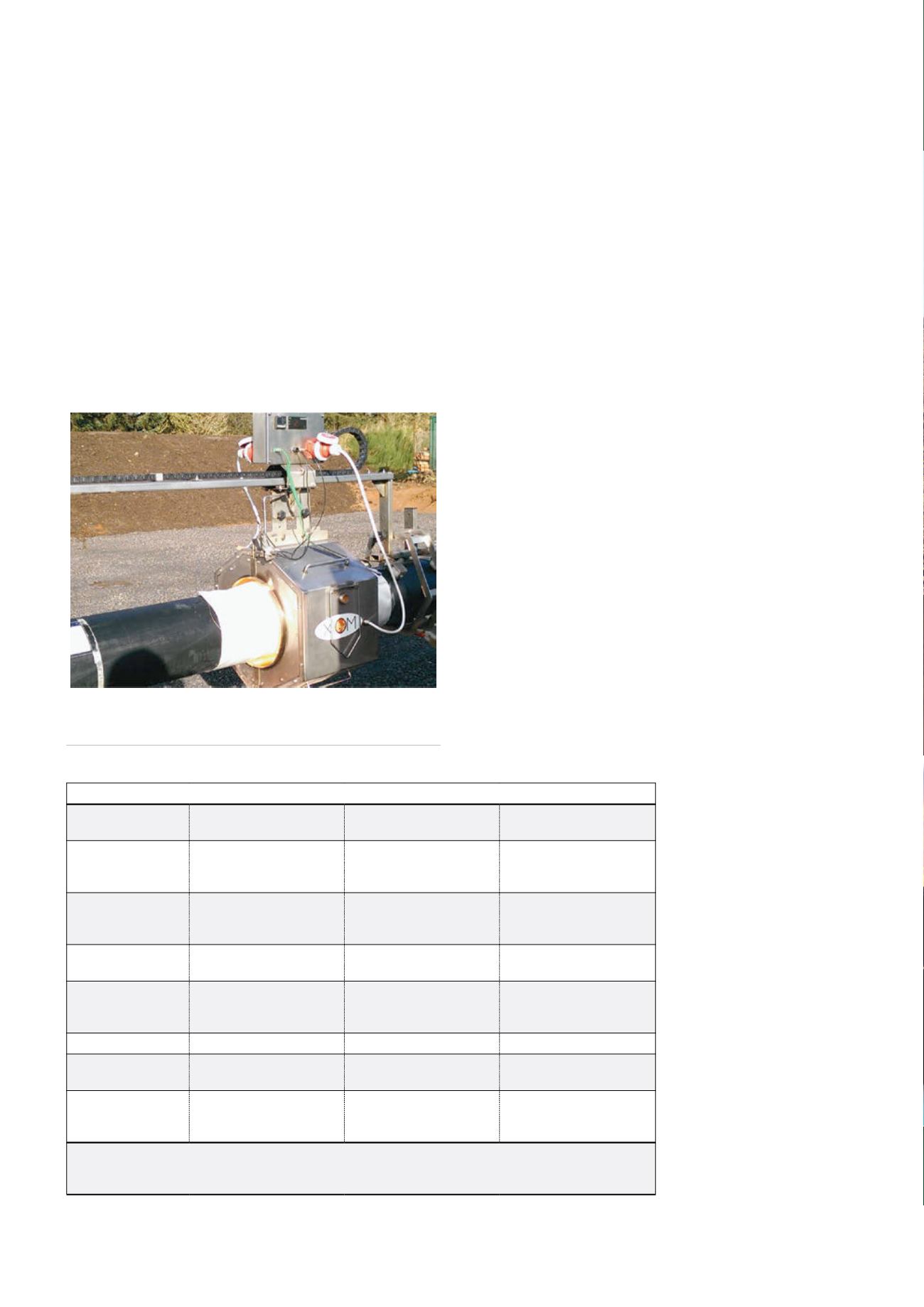

The heating unit and control unit are mounted on a

support frame that is clamped on to the pipe that spans

the field joint area. The heating unit is wheel-mounted,

which allows it to be moved along the support rail to heat

the field joint and to permit easy access for inspection of

the joint. The entire support frame is also wheel-mounted

so that the heating system can be moved to the next field

joint without the need to lift it from the pipe. This gives

the equipment excellent flexibility as well as the ability

to cover an area greater than one field joint width. The

small size and portability of the equipment means that

it can be used to coat field joints on pipelines in areas

where conventional induction heating and FBE application

equipment may not be suitable.

Coating application – flame spray

The most common method of application of FBE powder

coatings to field joints is with electrostatic spray.

However, an alternative method such as flame spray

provides a viable option, as it allows a more precise

control of film thickness and, with manual application,

allows field joints to be coated in difficult-to-access

areas during main pipeline construction as well as during

pipeline rehabilitation.

In the equipment package designed by XIOM Scotland

the flame spray guns are capable of an FBE powder output

of 7 kg/hr, and are powered by a mixture of compressed

air, oxygen and propane gas. This combination gives a

clean and controlled application of the FBE powder with

around 98% transfer efficiency. A single operator can easily

handle the coating application on smaller diameter pipes

up to around 20 in. OD, but for larger diameter pipes, up

to 30 in. OD, it is preferable to use two operators, spraying

in tandem, on opposite sides of the pipe.

Central Asia

A major multinational oil and gas company, with extensive

interests in central Asia, planned the construction of

further insulated pipelines with an external coating system,

comprising dual-layer FBE powder coating, together with

polyurethane foam thermal insulation encased in a hard

polyethylene outer sleeve. The dual-layer FBE system

was composed of Nap-Gard® 7-2500 from Axalta Coating

Systems as an anti-corrosion first layer, and Nap-Gard

Gold 7-2504 as a high temperature resistant, moisture-

barrier topcoat. This dual

powder system (DPS) met

the requirements for a

coating that could offer

a high degree of both

damage resistance and

corrosion protection up

to the 120˚C maximum

design temperature of the

pipeline and also in the

extremely severe ambient

temperature conditions in

the region that ranges from

-30˚C in winter to 45˚C in

summer. The terrain through

which the pipelines passes

includes extensive swampy

areas that necessitated the

requirement for the external

coating system to provide

excellent resistance to

water penetration.

The presence of thermal

insulation on the linepipe

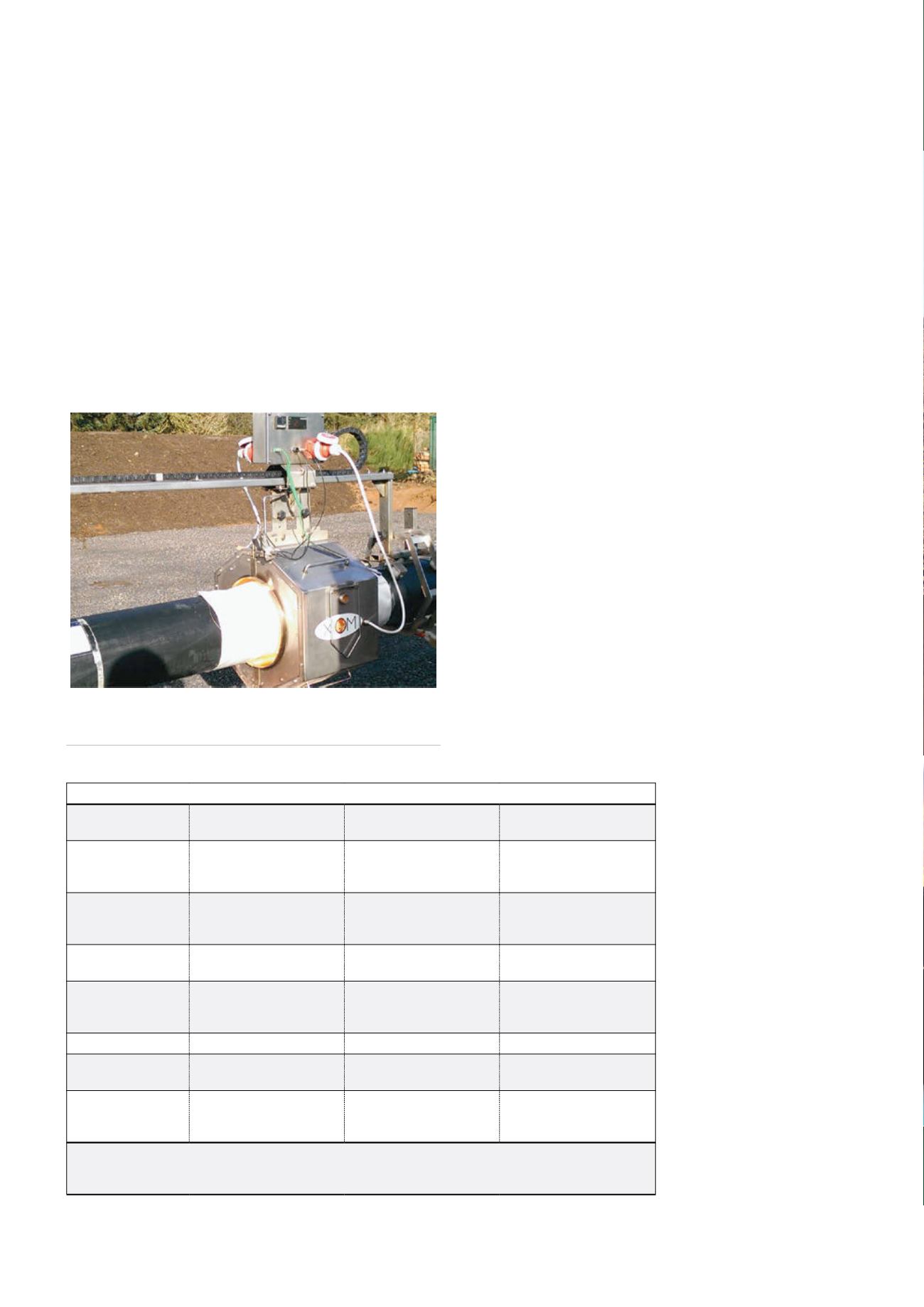

Table 2. Inspection summary for field joint PQ

Test description

Test method

Acceptance criteria

Result

Nap-Gard 7-2500 + 7-2504

Flexibility at: -30˚C

0˚C

25˚C

CSA Z245.20-14,

Clause 12.11

1.1˚/PDL, no cracking

1.7˚/PDL, no cracking

1.7˚/PDL, no cracking

Pass 1.8˚/PDL (*)

Pass 1.8˚/PDL (*)

Pass 4.6˚/PDL (*)

Cathodic

disbondment

48 hr, 95˚C, 1.5V

CSA Z245.20-14,

Clause 12.8

8 mm max. radial

disbondment

4.8 mm avg.

Hot water soak

48 hr, 95˚C; adhesion

CSA Z245.20-14,

Clause 12.14

Rating 1 - 2

Rating 2

Impact resistance

at 25˚C

CSA Z245.20-14,

Clause 12.12

(ASTM G14)

1.5 J, no holidays

Pass, no holidays

Hardness – shore D ASTM D2240-74

85 - 90

Pass 90

Penetration

resistance

ASTM G17

Max. 25 µm at 25˚C

12.7 µm

Degree of cure

(TA instruments

Q100)

CSA Z245.20-14,

Clause 12.7

-2˚C <

Δ

Tg < 3˚C

Δ

Tg -0.03˚C avg.

Note (*): The project specification requires 2% strain flexibility at -30˚C and 3% at 0˚C/25˚C. This equates to

1.1˚/per pipe diameter length (PDL) and 1.7˚/PDL respectively.

Figure 3.

Preheating of grit blasted line pipe joint to 180°C

using XIOM Scotland flame spray equipment prior to

application of Axalta FBE dual-layer coating stystem.

136

World Pipelines

/

AUGUST 2015