contractors’

directory

2015

MAINTENANCE

HORIZONTAL

DIRECTIONAL

DRILLING

OFFSHORE

PIPELINES

96

ONSHORE

PIPELINES

WELDING

REHAB

RESEARCH &

DEVELOPMENT

TERMINALS

FEASIBILITY

STUDIES

FINANCE,

STRATEGY

& ANALYSIS

COMPRESSOR

STATIONS

TURNKEY

CONSTRUCTION

W

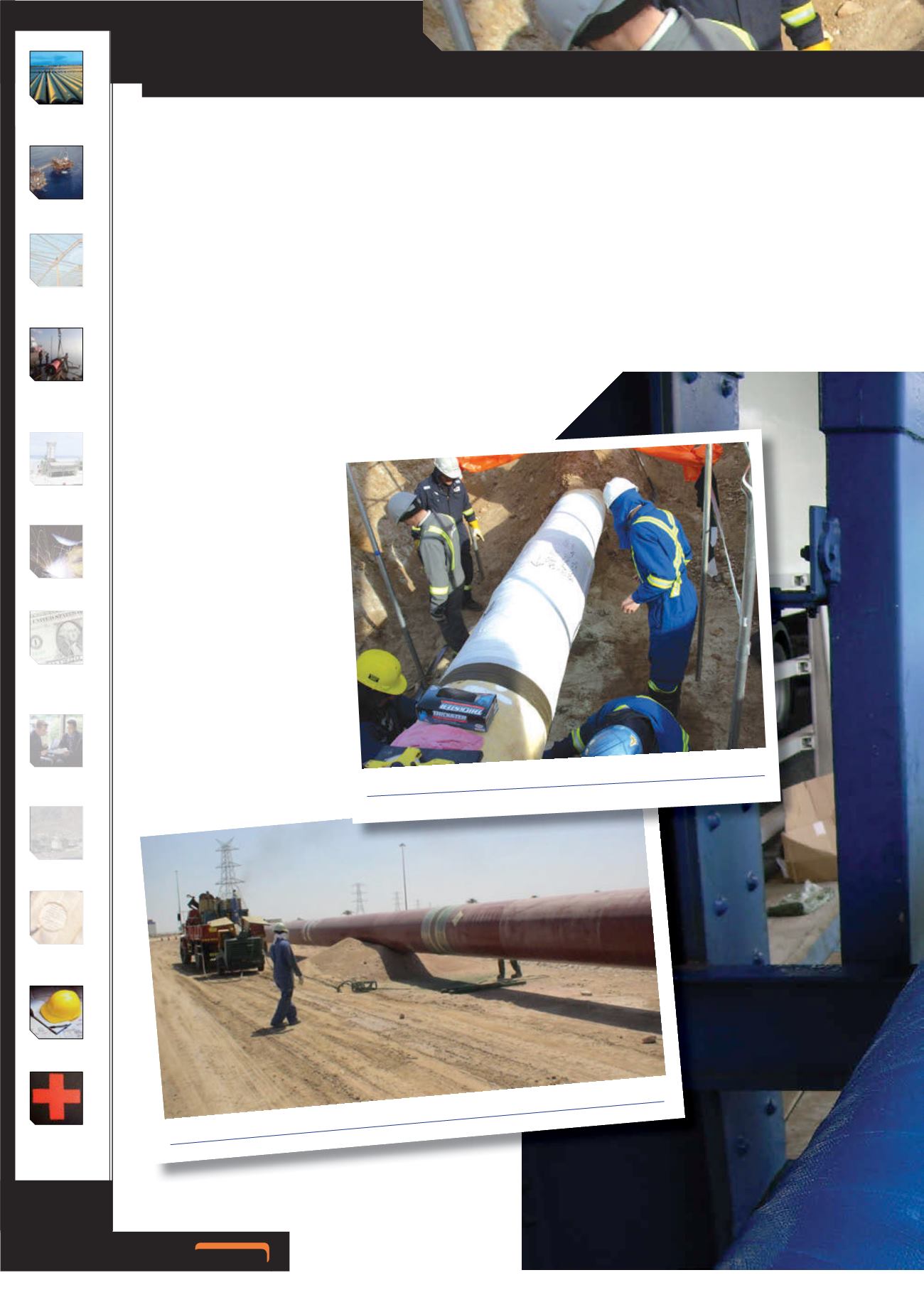

inn & Coales International has been

providing corrosion prevention

solutions since 1929. Winn & Coales’

early association with corrosion

prevention was the manufacture in the UK under

license of Denso Tape, a flexible petrolatum tape.

It now provides a wide range of Denso corrosion

prevention and sealing products to a multitude of

industries.

With strategic manufacturing and distribution

plants in the UK, US, Canada, South Africa and

Australia, it can provide quality, cost-effective

products, quickly delivered to where they are

needed most.

The Winn & Coales Denso product range

comprises liquid coatings

and tapes for buried

and exposed pipeline

protection, marine pile

rehabilitation systems

and chemical and abrasion

resistant linings for full

internal and external

storage tank protection.

For over 25 years the

company’s Protal epoxy

liquid coatings have been

used to protect major

oil and gas pipelines. The

Protal coatings can be

applied by brush or spray

method and include fast

cure, high build epoxies

for a variety of above and below ground corrosion

prevention applications. The coatings can easily be

applied in high and low temperature environments

and they are also great for protecting girth welds,

tie-ins, cadwells, fittings, fabrications repairs to FBE

and rehabilitation to existing pipelines. The Protal

coatings are high build, up to 50 mm in one coat.

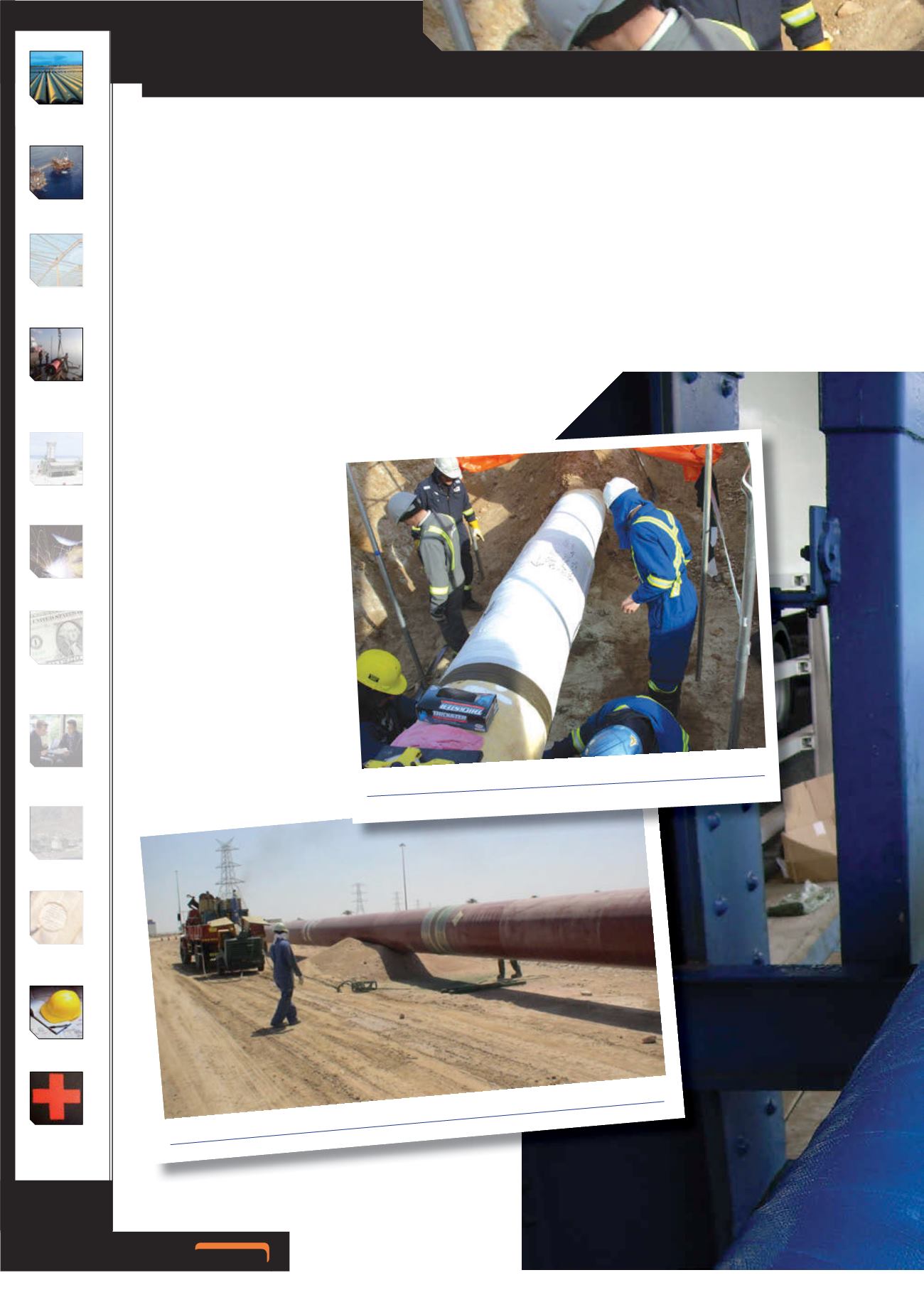

Recent oil and gas pipeline projects:

F

Derry Gas Pipeline, Northern Ireland: pipeline

protected with the Denso Steelcoat 100/400

System.

Liquid Fuel Pipeline, Dubai, UAE.

Pembina NPS 20 Pipeline, Canada.

Winn & Coales International