It is on this basis that new brine

minimisation or treatment technologies

are needed to address the brine in a

consumptive manner to extend the life

of current and new brine ponds, as well

as to eliminate the need for construction

of additional brine storage facilities. A

number of brine treatment or

minimisation technologies, such as

Eutectic Freeze Crystallisation,

HybridIce and Ion Exchange

technologies have been developed and

tested on a laboratory/pilot scale under

the auspices of Coaltech, a collaborative

coal research association in South Africa.

Brine treatment, as opposed to brine

minimisation technology, also has the

potential to produce revenue from the

pure salt byproducts generated; this

mitigates some of the operating costs.

Passive water treatment

Recently, there has been a significant

drive in the development of

cost-effective passive treatment systems

for the treatment of mine-impacted

water or minimisation/prevention of

acid mine damage (AMD) generation as

long-term sustainable solutions that can

be implemented. These technologies

mitigate the requirement for major

infrastructure or sophisticated levels of

operational maintenance. They minimise

waste generation and have reduced

energy requirements, thereby reducing

the carbon footprint of the process.

Passive treatment systems utilise the

chemical, biological and physical

removal processes that occur naturally

in the environment to modify the mine

water characteristics.

Avariety of passive treatment

systems, particularly constructed

wetlands, anoxic limestone drains,

vertical flow systems, such as successive

alkalinity producing systems and open

limestone channels, have been

developed that do not require

continuous chemical inputs and that

take advantage of naturally occurring

physical, chemical and biological

reactions to treat AMD in a controlled

environment.

Frequently, more than one type of

passive treatment or an integrated

system of passive treatment technologies

is employed to treat mine drainage in

order to achieve the required discharge

criteria. For example, ecologically

engineered ecosystems, such as

constructed wetlands, have been shown

to remediate contaminated mine water

but need to be properly planned,

designed, constructed and monitored.

These systems emulate the assimilative

properties of natural wetland in an

environment that can be controlled and

manipulated to ensure treatment

objectives are achieved. These systems

are, however, mostly designed to deal

with metal loads and pH rather than

sulfate removal; therefore, research is

required to address that particular

aspect of treatment.

Water stewards

Mining has received negative publicity

in recent years because of a legacy of

mismanagement of contaminated mine

water and AMD. As such, mining

companies need to take a leadership

role in water stewardship, preventing

impacts where possible, mitigating

impacts that cannot be prevented and

being innovative about solutions to

the issues that the industry has

created.

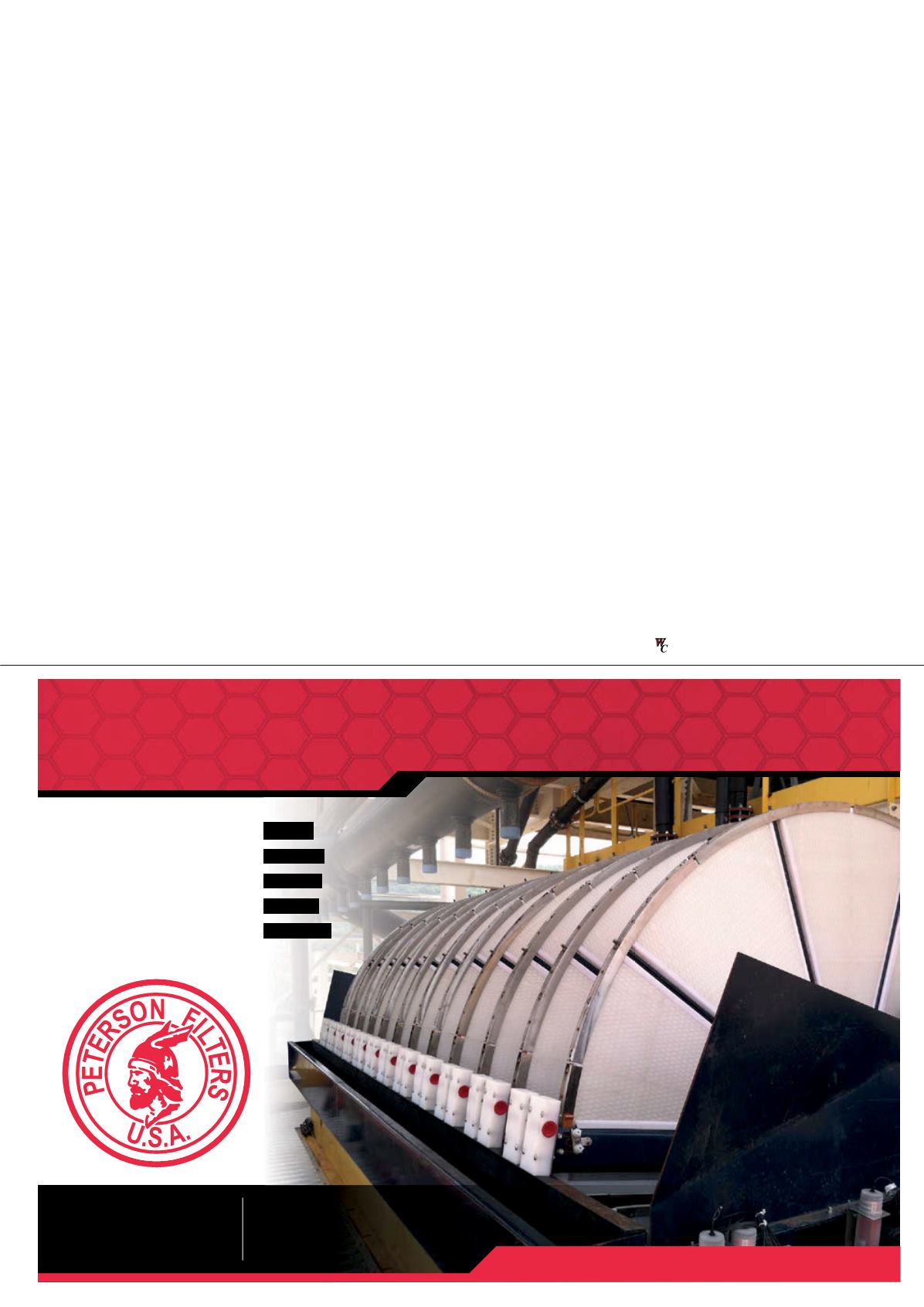

Peterson Filters Corporation

designs and manufactures high quality

industrial vacuum filtration equipment

for the mining and process industries,

including innovative custom accessories

that enhance their operation.

CorPorate oFFiCe

801-487-7761

PO Box 606

Salt Lake City, UT 84110

eastern Field oFFiCe

304-469-2978

PO Box 48

Oak Hill, WV 25901

|

New Solutions to Old Problems

Continuous filters and processes for industrial liquid-solid separation