June

2015

Oilfield Technology

|

49

TheUticaShale

In the Utica Shale of Ohio, build rates are often elusive and

laterals typically extend 8000 ft or longer. The newest member

of the DF516T family of curve and lateral bits is providing

one operator enhanced curve and lateral performance on its

initial runs. Plagued with inconsistent curve performance,

the operator has been forced to pull out of the hole partway

through the curve to pick up a higher bend motor, which also

necessitates another trip once the curve is landed to dial

back down for the lateral. Planning for one BHA and requiring

three quickly adds up to cost over‑runs. On its first two runs

in Harrison County Ohio, the 8.5 DF516TV5 has completed

the curve at a high rate of speed and TD’d the lateral. When

compared to an offset well using another bit, the DF516T saved

two trips. Eliminating these trips resulted in cost savings of

US$100 000 (cost estimate based on trip rate of 1000 ft/hr and

assumes operator spread rate of US$60 000/d).

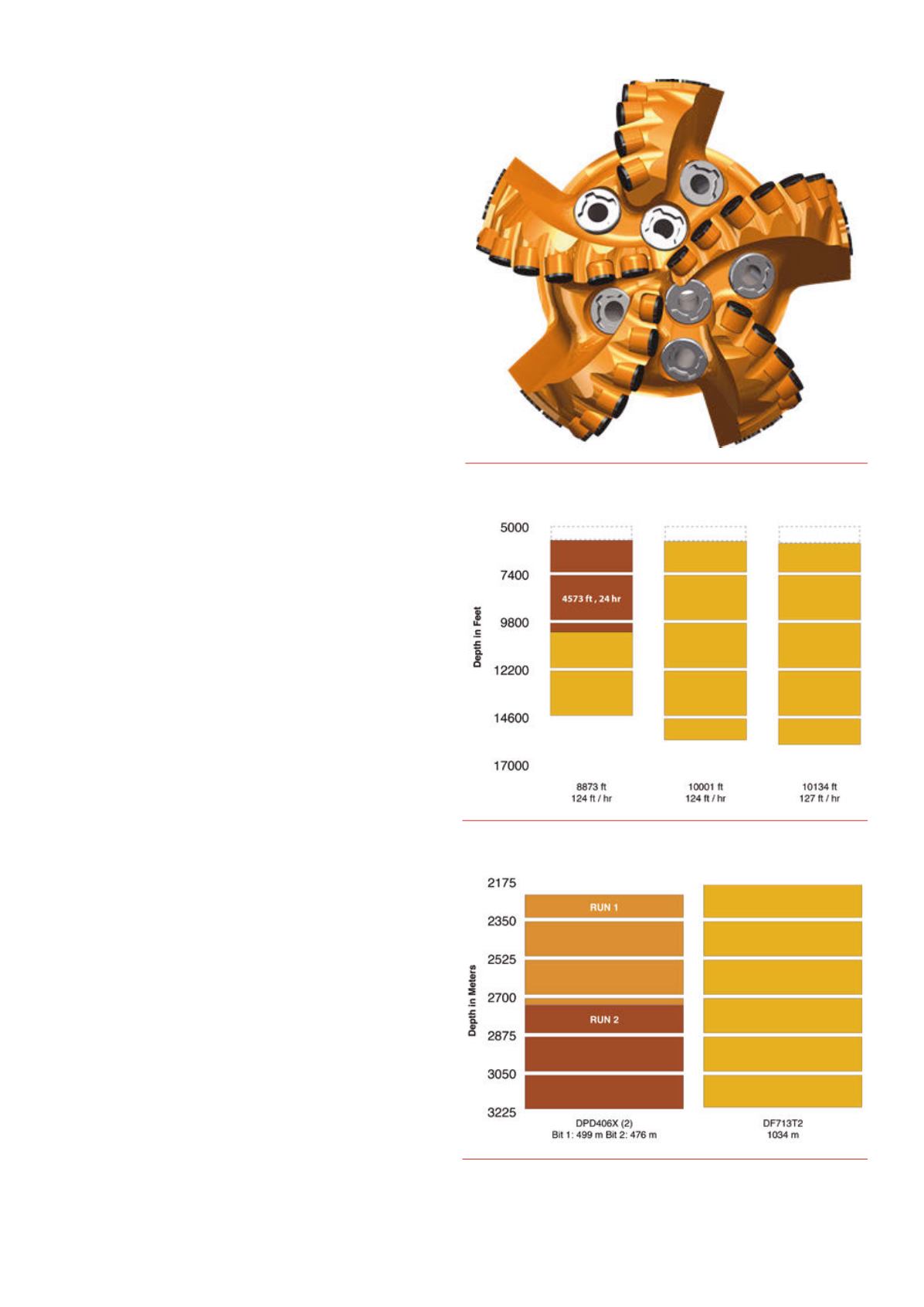

Making it throughtheMarcellus

The Marcellus Shale is the most prolific gas producer among

unconventional plays. Characterised by higher mud weights,

wildly varying dip angles, and deposited above a very hard

lime that is embedded with chert, the lateral interval can

be treacherous and challenging. In addition to the hazards

and geological challenges, a drill bit must be capable of

tracking extremely well to maximise the time operators

spend rotating when they do not have to adjust for target

changes. One operator in the Pennsylvania Marcellus is

steadily knocking down very long laterals with the 8.75 DF516T.

Drilling 10 000 ft and more and ‘coming out green’ is standard

for the DF516T. The operator recently recorded their best day in

the lateral with 4573 ft in one 24 hr period.

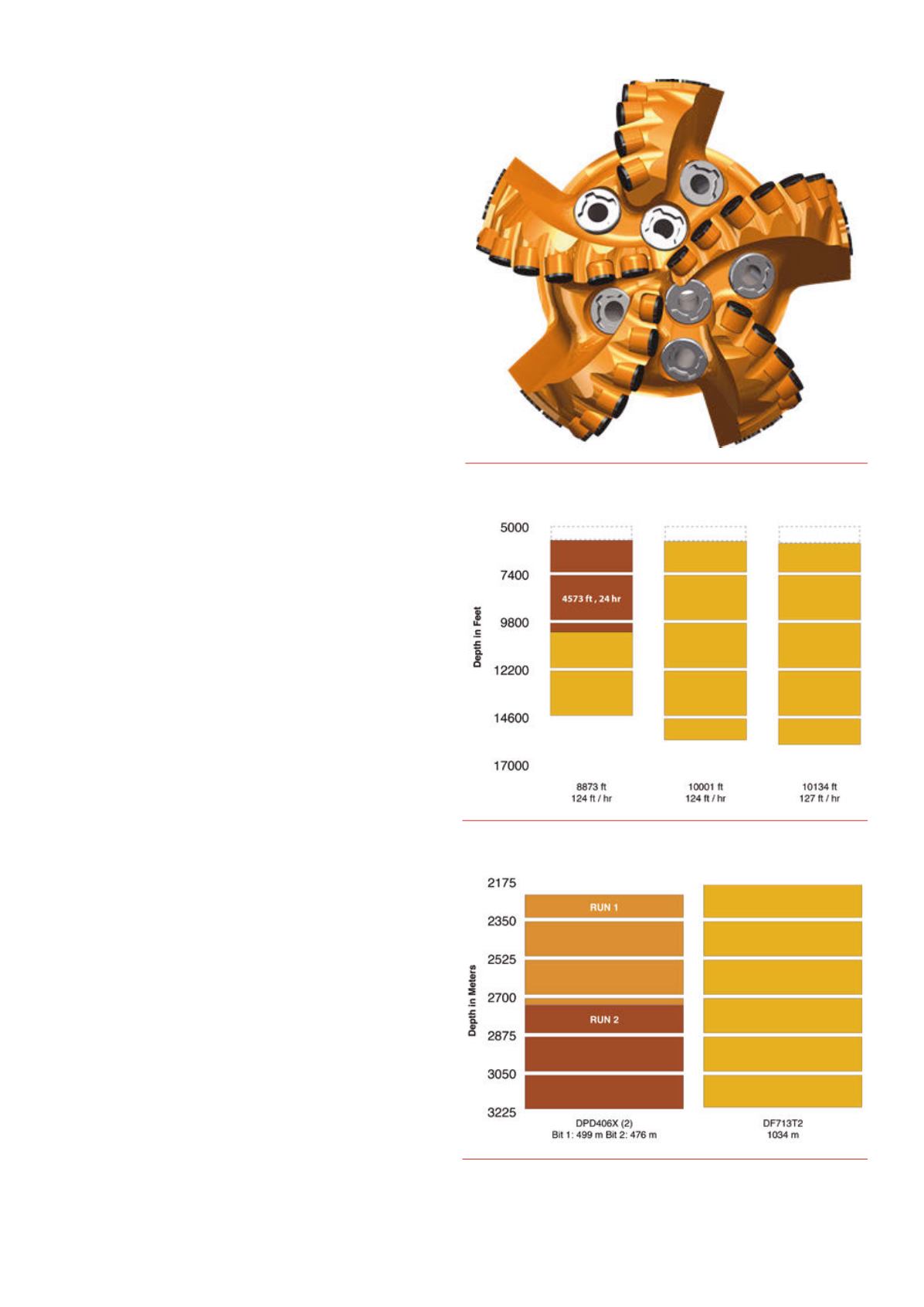

TheCanadianfoothills

In the Canadian Foothills of Western Alberta, operators drill

challenging horizontal wells through different target formations.

The rich oil and gas fields in the Foothills challenge operators

with hard and abrasive formations that damage and slow

down lateral bits, often forcing multiple trips to replace the

bit. During the 2015 Canadian drilling campaign Drilformance

analysed dulls of the previous generation DF713T2, made

adjustments to the cutting structure, and now offers operators

a bit that has shown significantly increased durability. This

has been demonstrated across multiple fields in the Foothills

area including the Valhalla, Pouce Coupe, and Sundown fields.

Highlights include drilling at an average 47% faster ROP, 46%

further, on average, 205 m more per run than other bits. The

DF713T2 utilises an efficient and durability‑biased cutting

structure and is built using extremely abrasion resistant

thermally stable diamond PDC cutters. These cutters utilise

a multi‑modal small grain size diamond feed and undergo a

multi‑step HPHT process. The technology has improved on

former impact weaknesses at a satisfying pace. The performance

of the DF713T2 equipped with TSPs has resulted in the

completion of exceptionally long runs.

Settingthepace inOman

Improved efficiency is a universal desire for any business.

While the Middle East is renowned for rich energy resources

that remain economical despite decreased commodity prices,

the oil companies of the region set aggressive goals for

performance improvement. Over time, technically demanding

Figure 6.

In theDoig formation in the Valhalla field, same operator same rig,

DF713T2 completed interval in one run versus a competitor’s two runs, saved

an estimated 18 hr trip, andaveraged 47%faster ROP.

Figure 5.

The 8.75DF516T drills threeMarcellus curve/laterals ina rowat

over 120 ft/hr. Two of the runswere >10 000 ft.

Figure 4.

The 8.5DF516T consistently drills 8000+ ft curve and lateral

intervals in Appalachian Shale plays.