50 |

Oilfield Technology

August

2015

Mainair compressorpackage for theShahDeniz

oilfield

Comprised of three ZR500 water cooled screw compressors, a

closed circuit water cooling system, three heatless dryers and

separate ZT110 black start screw compressor for emergencies,

the package was purpose designed, built and fully tested at

Atlas Copco’s Systems Hemel Hempstead workshop before being

delivered to the Shah Deniz project.

Once installed, the main air compressor package will provide

instrument air for pneumatic controls and actuation of critical

valves and instruments on the offshore platform. Under normal

operating conditions, two of the compressors will be running

continuously to provide 100% of the platform’s instrument air

requirements. However, in the event of non‑availability of one of

the compressors, the third, standby compressor, will start and

provide the necessary capacity. In the event of a power failure

and loss of the main air compressor package, the black start

air compressor, which is supplied by the platform’s emergency

power generator, will start and provide the minimum

compressed air needed to safely shutdown the

platform operations.

Logistical challenges

The delivery of the package marked the completion

of another major project by the team at Atlas Copco

Systems Hemel Hempstead.

As with most orders received by the facility, the

brief for the Shah Deniz package came with a very

particular set of specifications.

Not only did three heavyweight compressors

need to be combined on a single skid but a number

of ancillary items were also required, and the entire

package had to be sufficiently robust to withstand

harsh and fluctuating environmental conditions.

Due to the exposed nature of the offshore

platform where it was to be installed, the

main air compressor package needed to be

weatherproofed, winterised and built to withstand

harsh environmental conditions including high

wind speeds of up to 45 m/s and ambient air

temperatures ranging from ‑7 ‑ +40˚C at high relative

humidity. Designed for continuous 24 hr operation,

the package was tested to withstand inertial

accelerations as a result of seismic activity and

was also soundproofed to operate with low noise

emissions.

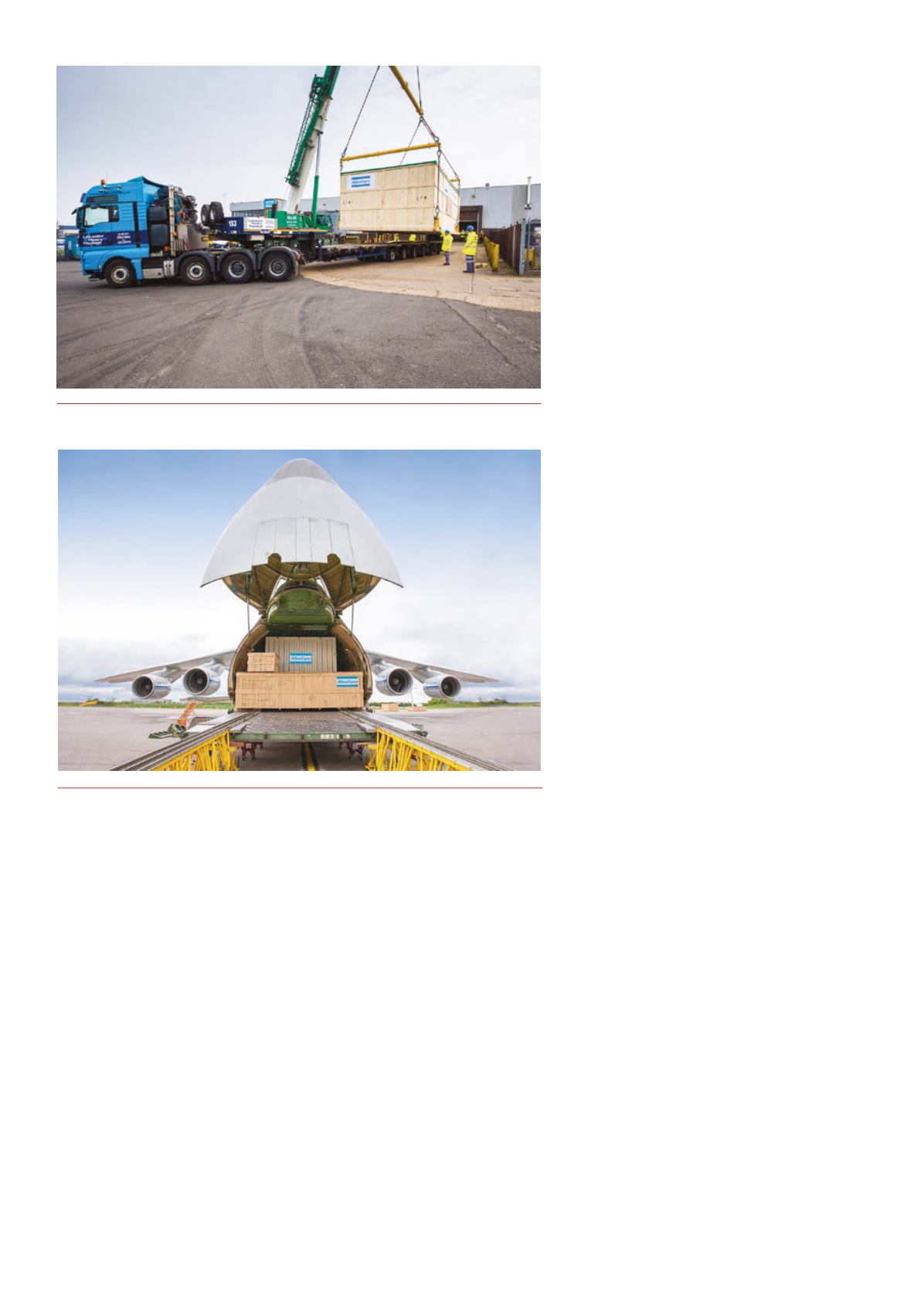

The physical size of the main air compressor

package, which is over 11 m long, 6 m wide and

3.75 m high, meant it had to be delivered in a

reinforced crate along with specially designed lifting

equipment to support offloading and handling at its

destination. This brought the total size of the final

delivered package to almost 90 t, which was moved

from the workshop using a 12 t fork lift truck onto

the back of a special heavy load bearing lorry that

travelled via police escort to Immingham docks for

shipping to Baku. During transit, the package then

travelled via canal, timed to avoid freezing weather

conditions, from the Black Sea into the Caspian Sea

for installation on the platform.

PackagedsystemforKazakhstan

Despite its extraordinary requirements, the Shah Deniz project

provides a useful illustration of the type of demands handled

by Systems Hemel Hempstead in the UK, one of Atlas Copco’s

six global competence centres that create and assemble bespoke

compressed air and nitrogen generation installations for the oil

and gas industry.

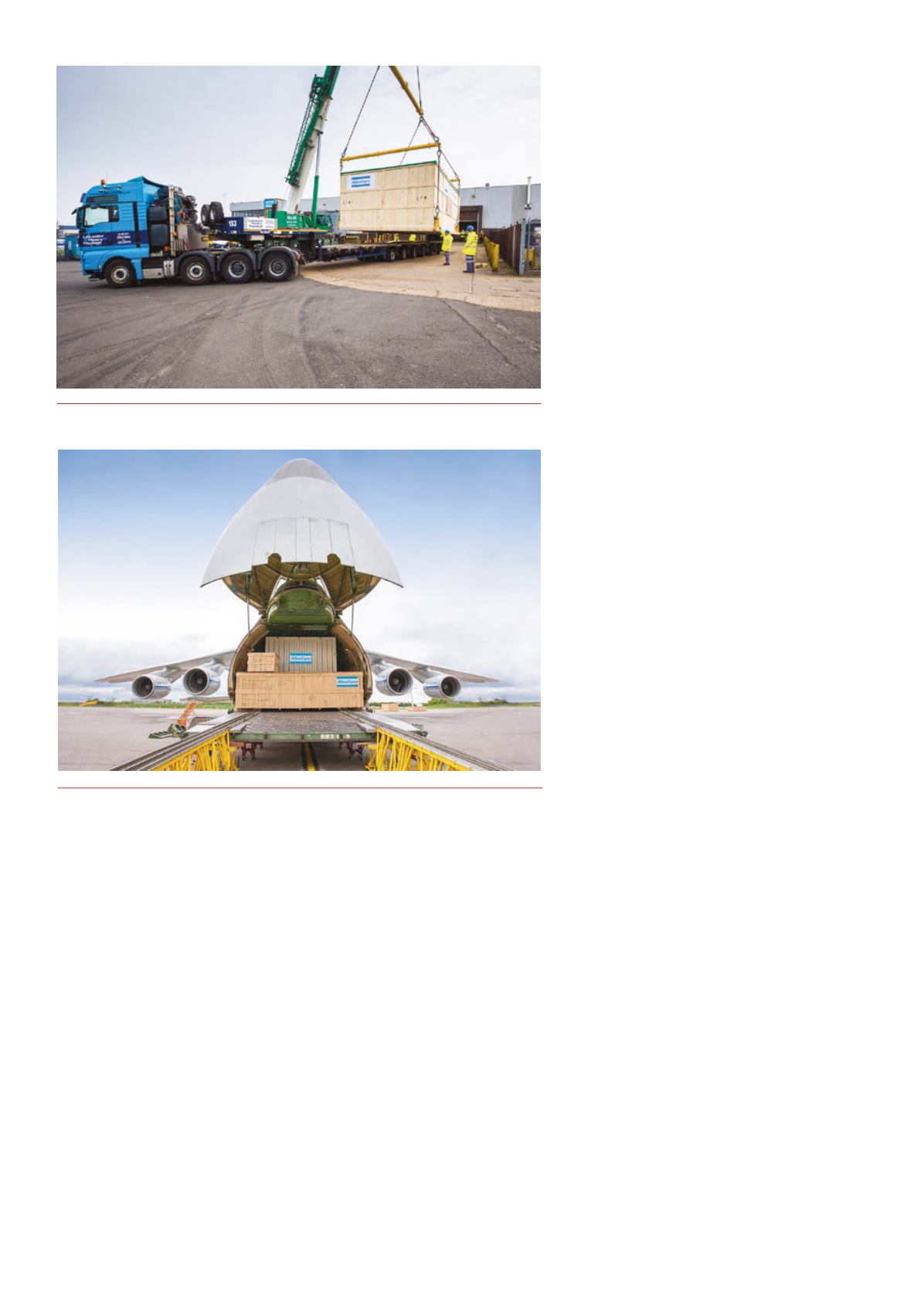

In 2012, the company completed the delivery of its largest

ever order designed and built in the UK. The system, comprising

instrument and process air compressor modules, and worth in

excess of £6 million, was so large in scale that one of the largest

air freight transporters in the world, the Antonov 124, was

commissioned to deliver it to Kazakhstan, where it continues to be

deployed as part of a major oil and gas project.

The four modules had to be fitted with special ‘D’ rings so that

they could be pulled, with just millimetres to spare, into the front

loading bay of the Russian‑built Antonov 124 and then secured

during flight.

Figure 1.

Recent package for the ShahDeniz project during loading.

Figure 2.

In 2012, Atlas Copco commissionedan Antonov 124 to transport its largest ever

package to a customer based inKazkahstan.