60 |

Oilfield Technology

August

2015

system at a later time, if required. This capability makes it possible to

build up a collection of calibration parameters tailored for different

situations, and the FSE can then choose the coefficient that gives the

best performance in the current situations.

Challenges inMPT

When the MPT telemetry systemwas introduced it provided data

rates faster than 6 bits per second. Over the course of time, as the

market demand for high-speed telemetry increased, several additional

challenges surfaced.

Ì

Ì

More demanding mud properties and deeper wells required manual

assistance to detect the TS, putting a higher workload on the FSE.

Several factors contribute to this and must be addressed:

h

h

Some frequency contents of the TS can be strongly attenuated

by the mud system. This situation mainly happens when using

mud systems with a high PV or in very deep wells.

h

h

The training sequence can be distorted by downhole or

surface noise that cannot be filtered out by the system. Pump

noise, in particular, can be a problem under certain conditions.

h

h

The system is designed for the use of two pressure transducers

(PTs). On many rigs there are only two, but some would

benefit if the processing were performed on more available

PTs.

h

h

Manual assistance when the automatic TS detection fails is

cumbersome, and requires more training and attention from

the FSE.

h

h

The search requires a manual trigger. Automation would

remove this task from the FSE, giving time for more valuable

tasks.

Ì

Ì

The manual fallback options to calibrate the processing algorithms

require a high level of training to use them effectively. Only a small

percentage of all FSEs can use them. Most FSEs do not attempt to

use them, and instead choose to use a slower data rate.

Ì

Ì

Performing a new calibration by means of TS or fallback options

can only be done on the live system, and the new settings

are immediately applied. Field operations have shown that a

pre-testing of coefficients prior to their operation is needed.

Ì

Ì

Managing the acquired calibration parameters is difficult with their

rising number. It is not unusual to have several saved calibration

parameters that are used alternately, e.g., for different flow rates

and pump combinations, to reach optimum decoding. Problems

frequently arise from finding the correct coefficient file for the

current situation. A parameter management system is needed.

Ì

Ì

As modern drilling rigs appear, new mud pumps types and

dual derrick setups show that the surface mud flow line-up is

getting increasingly complex and requires rigging up several PTs

for decoding. On some installations up to 6 PTs are installed in

different locations to switch between different lines. The correct

combination of PTs has a significant influence on the decoding

performance, and finding the best combination on the live system

requires time. An automated, offline evaluation of the possible

PT combinations is needed.

Newsystemimprovements

After gaining much experience in the field, data sets were analysed

and user experiences were collected to improve the current system.

As a direct answer to the limitations, several major and minor

improvements were introduced to reach higher data rates and

improved robustness.

Ì

Ì

The detection of the TS was drastically improved. Several

improvements contributed to this achievement:

h

h

For deep wells and high-viscosity mud, the automatic search

of the TS was less reliable. The TS was expanded to lower

frequencies to reach higher robustness for those wells.

h

h

An improved noise cancellation technique was applied before

the TS was detected. This improved reliability.

h

h

The TS detection was expanded to all available pressure

channels, not just the ones used for decoding.

h

h

A manual selection possibility was added to the new system if

the automation failed.

h

h

The TS detection was automated, releasing the FSE from

performing the manual trigger.

h

h

The efficiency of the TS was improved through educated

changes, leading to shorter TS with improved decoding

quality.

Ì

Ì

The new system improved the reliability of the TS detection

tremendously for previously challenging conditions, eliminating

most situations where manual interaction was needed. Cases

requiring manual user selections were simplified in an easy-to-use

selection window where the user had to look for a characteristic

pattern.

Ì

Ì

New coefficient sets were tested on real data to generate

a decoding quality prediction. Changing conditions during

the transmission of the TS led to different qualities of the

coefficients. The user could select to apply coefficients based

on their performance. This avoided applying non-optimal sets

of coefficients directly to the real time system. In addition the

FSE would gain additional confidence in picking a good set of

coefficients.

Ì

Ì

A database of coefficient sets was created to assist the FSE

through automated saving of the sets with corresponding

additional information such as rig status, flow rates, active pumps

or decoding parameters. This further simplified the coefficient

selection to best match the current conditions.

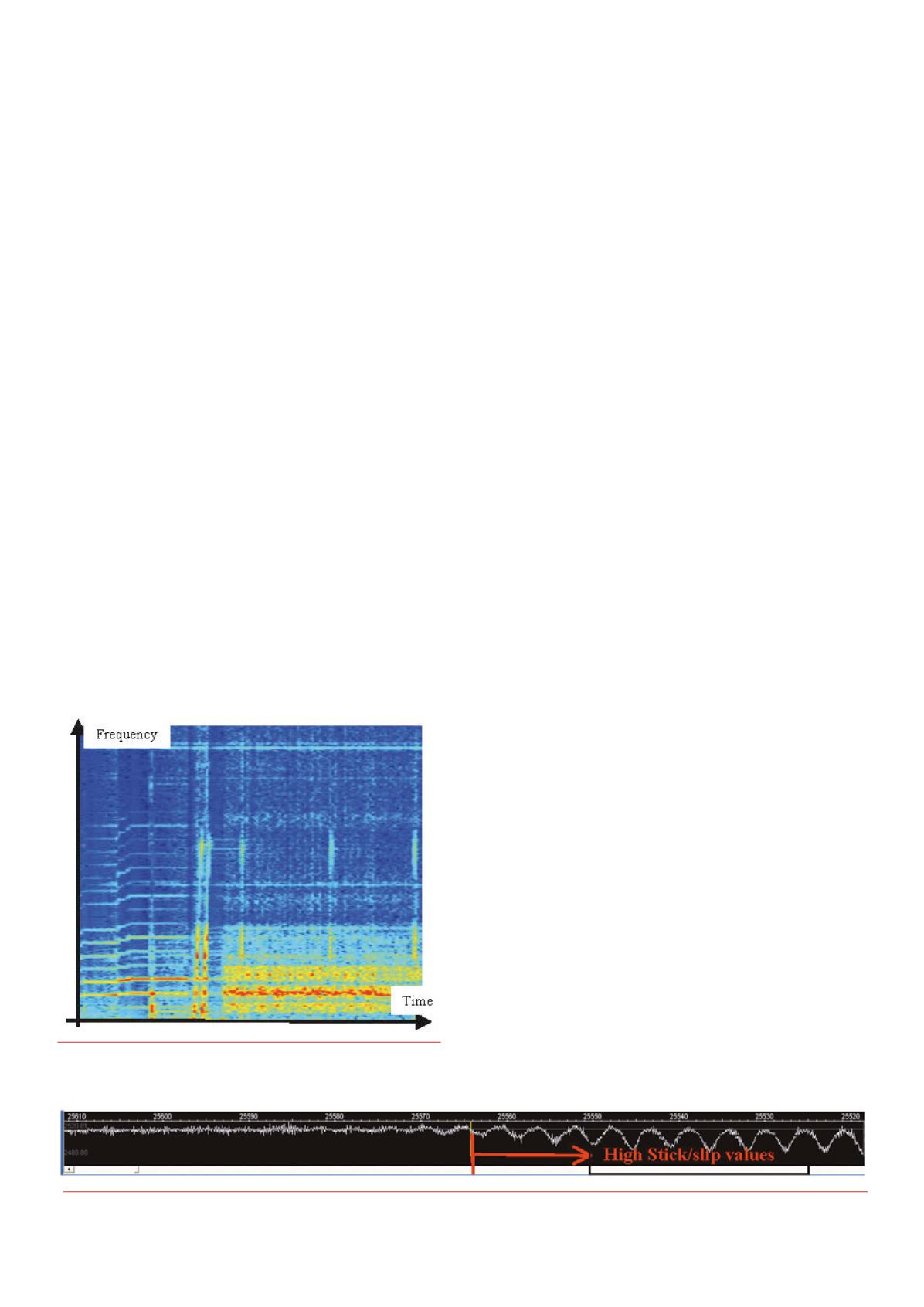

Figure 4.

Spectrogramof pressure signal whileBHA is at shallow

hole depth. Reddepicts strong signal content, blue showsweak signal

content.

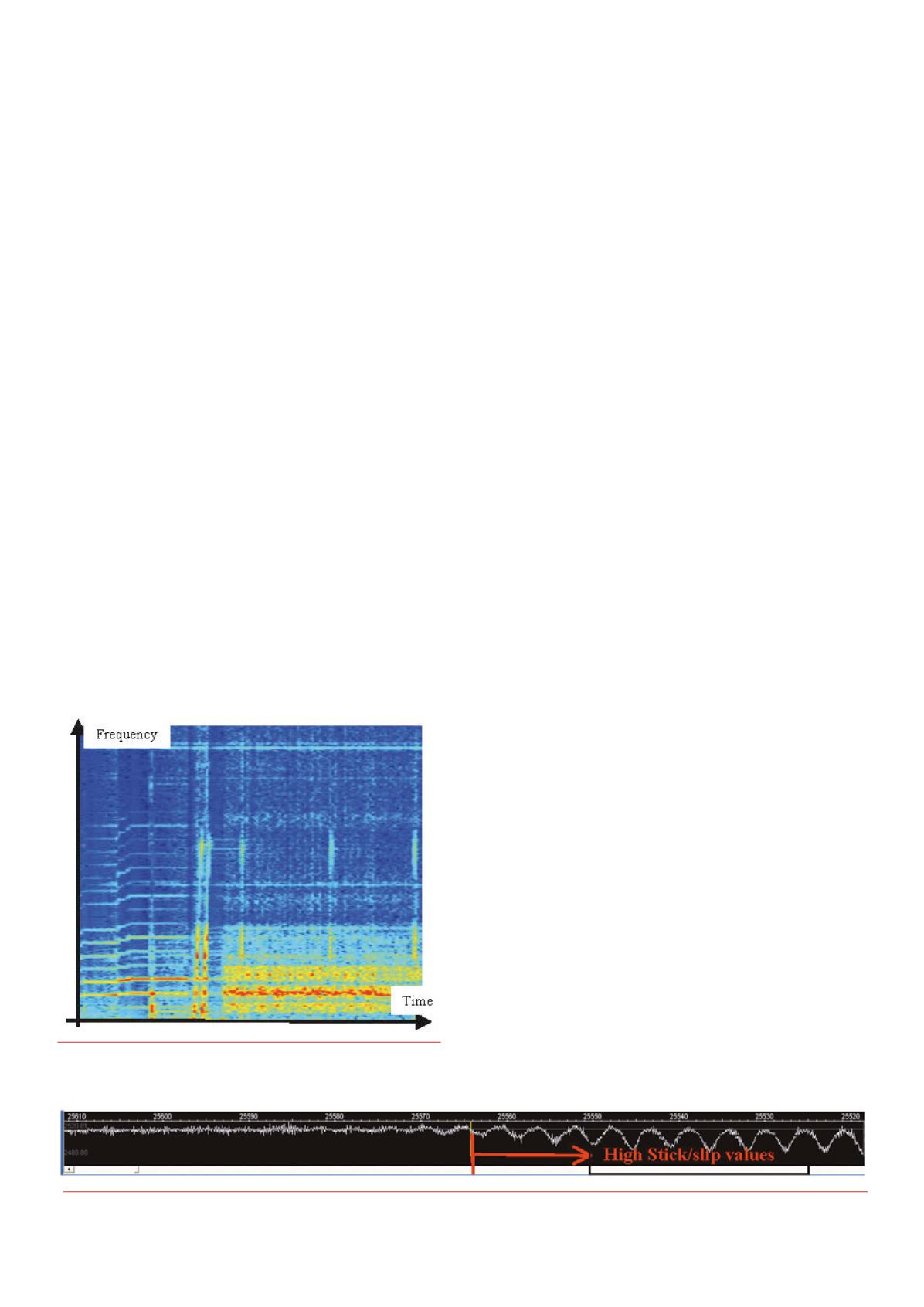

Figure 5.

Pressure signal before andduring high stick/slip in time domain.