HYDROCARBON

ENGINEERING

76

Through the use of a measurement system, the

accessories that aid in removing entrained solids and gas,

and the dedicated, dynamic volumetric prover, the error

of the system is held to a very small amount. A meter’s

error tends to be random for a constant set of conditions,

which usually cancels out statistically and can be

estimated and accounted for during measurement, unlike

systematic or biased error, which are consistent

measurement errors.

Tank gauging

A metering system’s accuracy and repeatability is superior

to another common technique for measuring custody

transfer transactions at tank farms: tank gauging. Tank

gauging is the measurement of static quantity volume of

liquid hydrocarbon products in bulk storage tanks, a

process used for inventory control, oil movement and

operations, leak detection, and, in some cases, custody

transfer. There are many factors in tank gauging that

impact the measurement and calculation of tank volume

and introduce a larger degree of uncertainty and potential

bias for error. Simply put, with tank gauging, there is more

opportunity for error in measurement, sometimes

significant. Often the errors found in tank gauging are

biased or systematic, based on environmental conditions

or limitations with the instrumentation that performs

measurement. These kinds of errors do not cancel out

statistically. Instead, they tend to accumulate and lead to

financial reporting errors.

The shape and size of the container, the tank, is often

subject to environmental stresses, which affect the

accuracy of measuring its volume. Tank walls expand in

the heat, for example, but not always evenly, sunlight

focused on one side of the tank can cause expansion.

Hydrostatic pressure can also change the shape of the

tank. Tank volume is also affected by deadwood, the

volume of the piping and other objects in the tank, as well

as from the effects of floating roofs. The weight of

product in a tank can sometimes cause a diaphragm effect

on the tank bottom, sinking when the tank is full. Tank

walls can erode, too, changing the volume. Sediment that

accumulates unevenly on the tank bottom can also affect

the measured volume inside the tank.

While tank imperfections are accounted for in tank

capacity tables (TCTs), which are used to calculate

product volume in a tank, they are usually based on

external measurements of the tank, which can miss

internal, undetected defects. Verification of TCTs occurs

only periodically, and might not account for changes in

the tank volume between inspection and verification.

Product characteristics sometimes cause error in

measurement by tank gauging. If the product in the tank

contains water, it can separate and settle at the bottom

of the tank. Volume calculations need to account for this

free water, which is fairly easy to do in product that is

lighter than water, such as light crude oil or refined

product. In that case, there is an easily discernable border

between water and product. But if the product is heavier

than water, thick crude oil, for example, free water forms

an emulsion and its exact level is difficult to calculate,

possibly causing error in measurement.

Particulates exist in product, and must be accounted

for, too. In order to determine the amount of solid

suspended in product, tank gauging relies on spot

sampling. If the solids are unequally distributed in the

product, spot samples may not accurately measure the

amount of solids, even if multiple samples from various

levels in the tank are taken. Any error in measuring the

solids causes error in tank gauging measurement.

Likewise, tank gauging relies on spot sampling to

measure temperature. The size and volume of terminal

storage tanks are quite large and, therefore, the

temperature of the product is likely to vary in the tank

and be incorrectly measured by spot sampling. Because

temperature is one of the largest variables that affect the

volume determination of product, spot sampling

temperature is highly likely to cause bias error in

measurement. Even if the product in the tank is regularly

mixed to reduce errors caused by spot sampling, there is

still chance of error from spot sampling.

The actual process of measuring through tank gauging

may contain errors. The likelihood of errors in tank

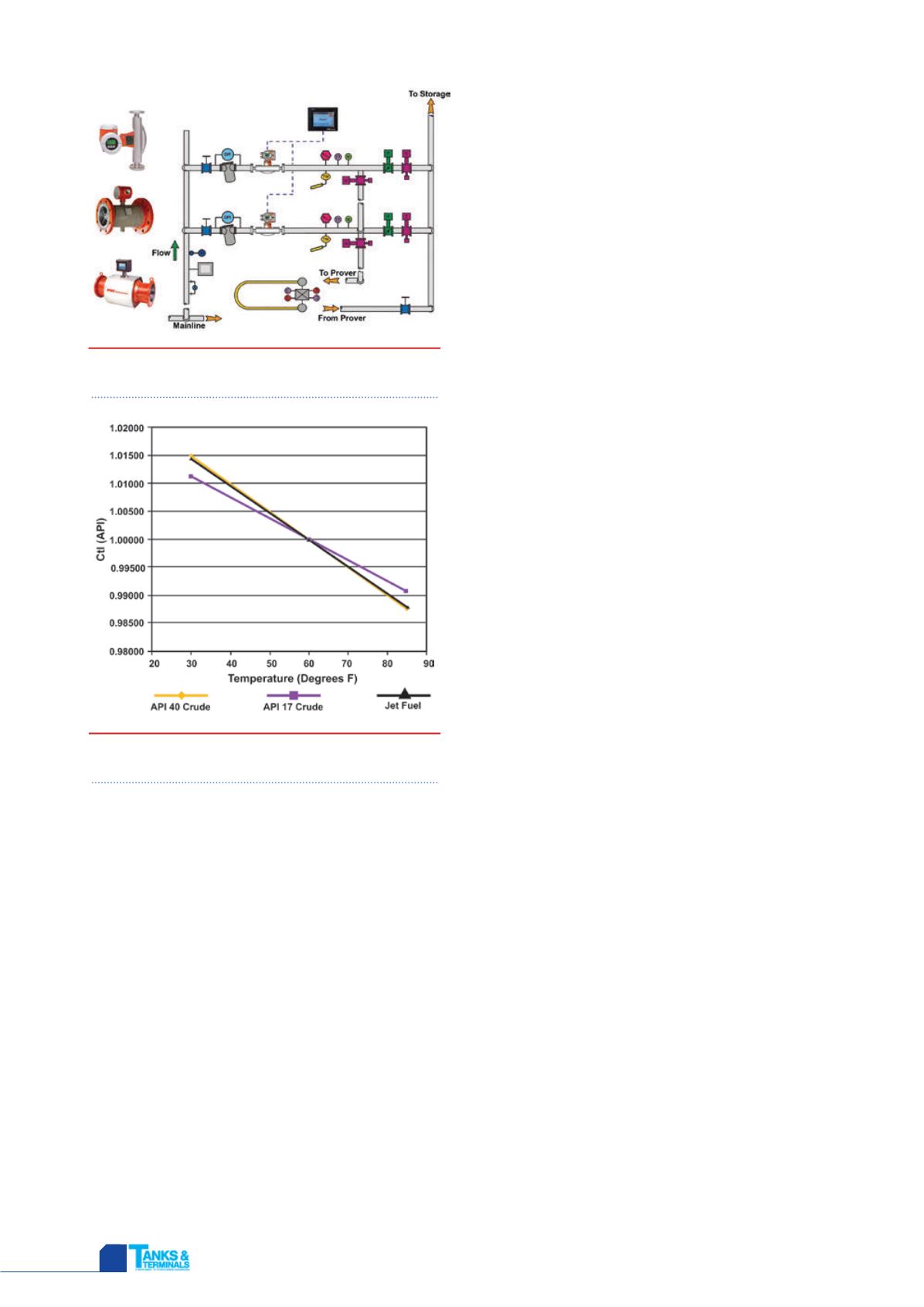

Figure 2.

Integration of dedicated volumetric

prover shown with various meter technologies.

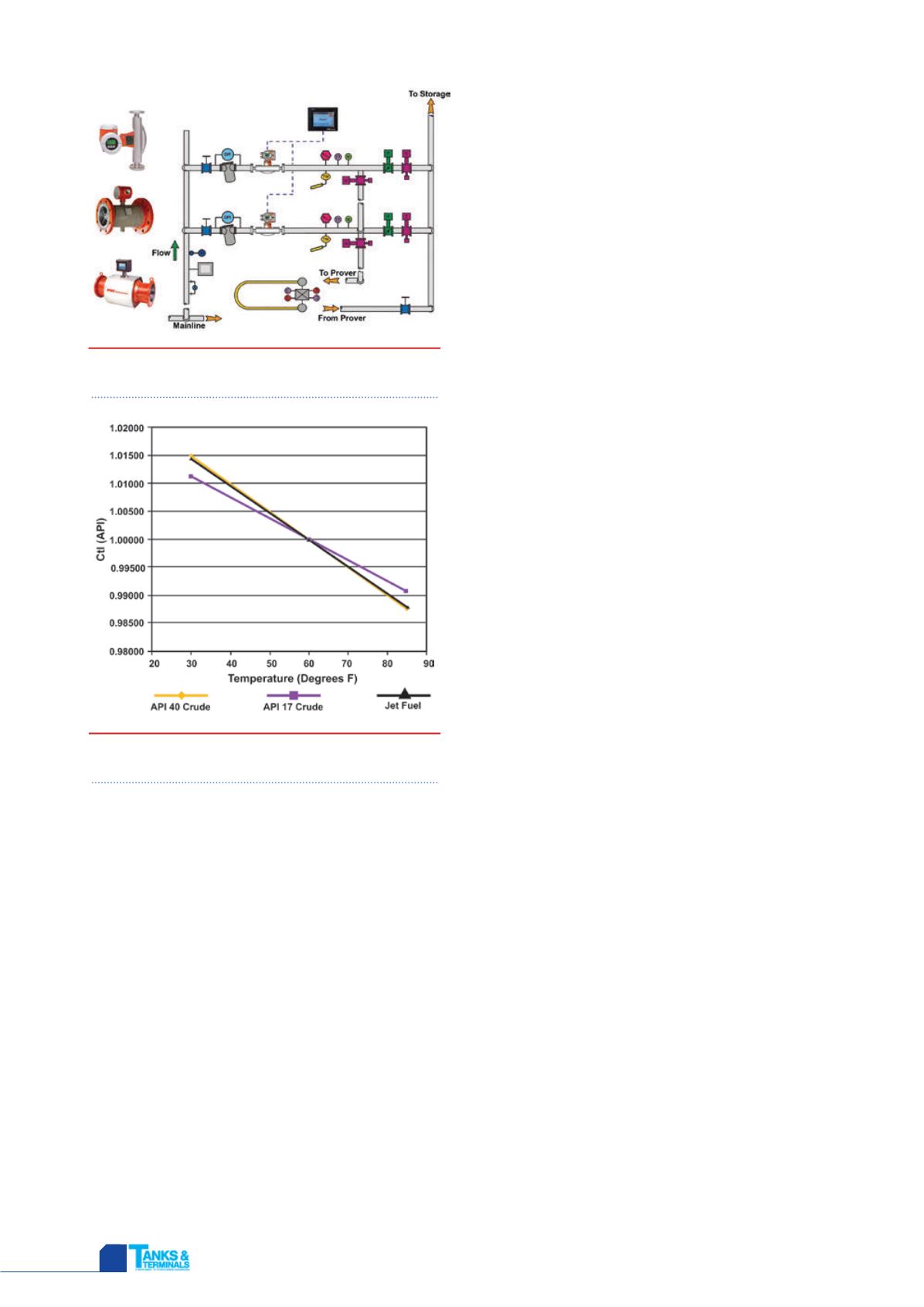

Figure 3.

Temperature effects on liquid and

utilisation to calculate the net standard volume.