HYDROCARBON

ENGINEERING

22

foundation options, such as ground improvement. This

sophisticated analysis offers cost effective foundation

possibilities that are not readily apparent when reviewing

the raw information in the soil data report.

Site specific seismicity study

The final component of a geotechnical survey is a site

specific seismic investigation and report, which outlines

the magnitude of the ground motions from seismic activity

and the influence of the soil.

The seismicity study defines the ground motion hazard

for the project location, determined by analysing many

variables, including but not limited to regional seismicity,

subsurface soil conditions, and proximity to known seismic

faults. The study also assigns a classification from A - E,

where Class A represents a site on hard rock and Class E

represents a site on soft clay soil. As soils transition from

stiff to loose, they are increasingly more prone to seismic

instability and lateral motion.

Additionally, the study provides information to

quantify the liquefaction potential of the site, or the

ability of the soil to shift and consolidate due to seismic

activities. This calculation, derived from the provided

acceleration rates and raw soil data, is then used to finalise

the foundation design in conjunction with the settlement

calculations.

Timing of a geotechnical

investigation

The best timing for a complete geotechnical investigation

is after the conceptual project design has been finalised,

but prior to inviting tank contractors to bid designs. Early

in a project development lifecycle, during the project

conceptualisation and feasibility analysis, a preliminary

geotechnical assessment will be performed as shown in

Figure 4. At the most rudimentary level, these assessments

commonly consist of a visual inspection of the site and a

review of any previously documented information.

While this assessment assists in determining plausible

terminal or facility layouts, it is inadequate as the basis for

storage tank designs or firm pricing during the bid stage.

Furthermore, prematurely performing an investigation will

result in data not specific to the tank’s size, location, and

zone of influence, thereby rendering it marginally useful.

Rather, the complete geotechnical investigation, as

indicated in Figure 4, should be performed so the results

can be included with other customer specifications within

the bid package. Delaying the availability of this

information, to either later in the bidding process or even

after awarding the contract, severely limits the ability to

develop innovative technical solutions or pursue value

based engineering.

For example, soil improvement strategies, such as vibro

compaction, can eliminate the need for a deep foundation,

shortening the foundation construction schedule and

decreasing material and equipment costs. However, to

pursue this option, time during the bidding stage is needed

for the tank contractor to locate and obtain estimates

from specialty geotechnical subcontractors.

Therefore, these potentially cost saving alternatives

can only be achieved when complete geotechnical

information is made available as part of the bid package to

allow sufficient time to create accurate designs.

Utilising one geotechnical

contractor

To maximise the benefits from this early and complete

investigation, a single geotechnical engineer should be

used to conduct the full investigation. When third party

geotechnical engineers must be located and contracted to

perform the specialised skill of analysing the soil data,

precious schedule time is lost while waiting for the

supplementary reports. If a single party is used, fewer

design basis assumptions are made, which results in more

time to pursue value engineering options that benefit both

the owner and tank contractor.

Additionally, this approach improves consistency

across the investigation and reduces the number of

assumptions within each bid’s design basis. Because third

parties will produce reports and base recommendations on

data which they did not originally collect, these

recommendations may not be accurate, being either overly

conservative or overly liberal. This can translate to a

design inadequate for the location.

The impact of assumptions

on design, decisions, cost and

schedule

These incorrect assumptions can arise from incomplete

investigations, late availability of information, and

components generated from multiple parties. For example,

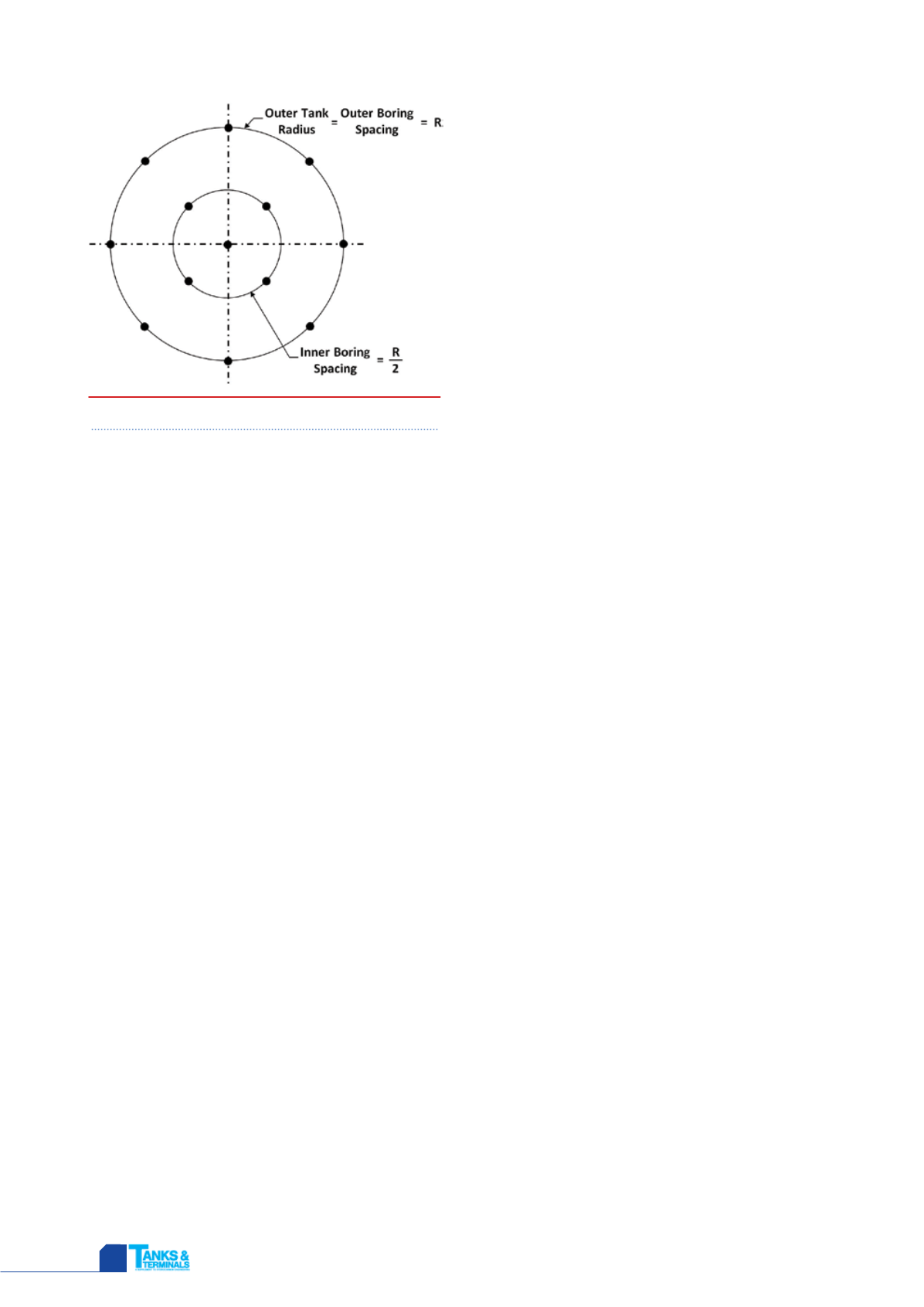

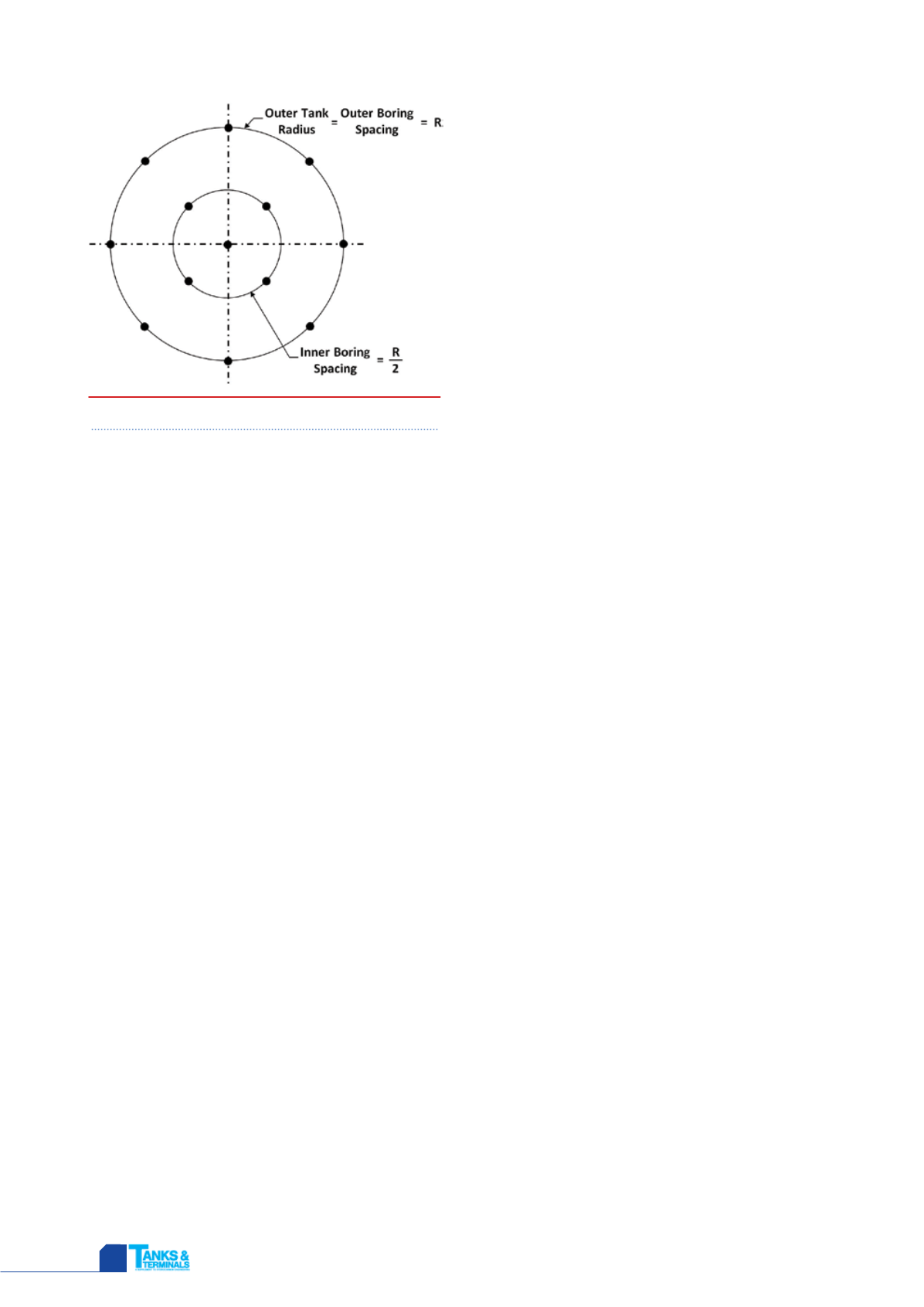

if borings are not spaced adequately to cover the zone of

influence, the soil profile can become overly generalised,

resulting in a risk prone liberal design or a costly

conservative bid. Incomplete seismicity studies can

indicate a higher classification rating, such as D or E, and

limit the tank geometry to a more expensive, yet sturdier,

short and wide tank. Problematic to owners, these

assumptions cloud the waters when deciding between

bids. As layers upon layers of assumptions are made, the

ability to identify what is assumed and what is known is

Figure 3.

Suggested Boring spacing.