Heavy-duty rear leaf springs,

rather than the JK Wrangler’s coil

springs, afford a maximum payload

of 2566 lb and a trailer towing

capacity of 7716 lb. Front coil

springs, shocks and a proven five

link suspension system provide

outstanding load capacity and a

comfortable ride. Frame members are

significantly reinforced and

strengthened for mining use at the

factory. The body is reinforced at

stress points to ensure tough,

trouble-free operation. Load Range E

BFGoodrich Rugged Trail all-terrain

tyres are mounted on 17 in. steel rims

for underground mining duty.

Operator comfort is much

improved from earlier Jeeps. Bucket

seats and air conditioning are

standard and combat occupant

fatigue, no matter how tough the

work environment. The J8 has

accessible lighting controls and

legible instruments, including a

tachometer, speedometer, oil

pressure gauge, water temperature

gauge, voltmeter, fuel level gauge

and a vehicle information centre to

advise the operator of systems

status.

The J8 uses the same diagnostic

equipment as the entire Chrysler

family of vehicles and that

equipment is available to any mine

operator. Chrysler warrants the

complete powertrain for 12 months

or 20 000 km. Using the vehicles

underground does not void the

warranty. In fact, many mine

operators have submitted plans and

received approval to do their own

warranty work onsite. This allows

them access to the same technical

assistance available to any

dealership. “Not only is a mine able

to buy the parts from a local

Chrysler Jeep Ram dealership, but, if

it invests in the tools and training, it

can actually service the trucks under

warranty at the mine,” said Betar,

making the mines mini service

centres and leading to a significant

reduction in downtime. Parts

catalogues are constantly updated,

available online or on CD, and

interactive online diagnostic

information and wiring diagrams are

available along with CD manuals.

Mining-specific

modifications

n

n

Base J8 chassis are available

in either two- or four-door

configurations with seating for

two or five people, respectively.

n

n

Flatbed or pickup‑style vehicles

are available in two- or four-door

configurations with customisable

wheelbases centred on customer

specifications.

n

n

Personnel carriers are available

with a capacity of up to 10

occupants.

n

n

Mine-duty front and rear

bumpers are available.

n

n

Custom engineered FOPS and

ROPS are available.

n

n

An engine-driven air compressor

capable of a constant 70 CFM at

100 psi is available.

n

n

A variety of modifications are

available to reduce overall height

to 65 in.

n

n

An enclosed wet disc

parking/emergency brake is

available.

n

n

A complete enclosed wet disc

braking system for both parking

and service brakes is currently

under development.

n

n

Overall top speed can be

governed to either 15 or 25 mph.

n

n

MSHA-approved fire

suppression systems are

available.

The J8 is the only vehicle (along

with the Ram Pickup) produced by a

major manufacturer in significant

volume that is being successfully

used in the underground market.

The Jeep J8 has the advantage of

parts and service availability that do

not lock the operator into going back

to the manufacturer for spares.

Additionally, parts and repair

procedures will remain as stable as

any other Chrysler vehicle. As parts

are produced in very large

quantities, costs are dramatically

lower than unique components and

are available for a much longer

period of time.

The Jeep J8 is ideally suited as a

robust and bare-essential mining

vehicle platform with its enhanced

cooling, air filtration system and

heavy-duty suspension system,

which doubles the payload of a

standard vehicle. The J8 meets

underground mining requirements,

cuts downtime and improves the

bottom line.

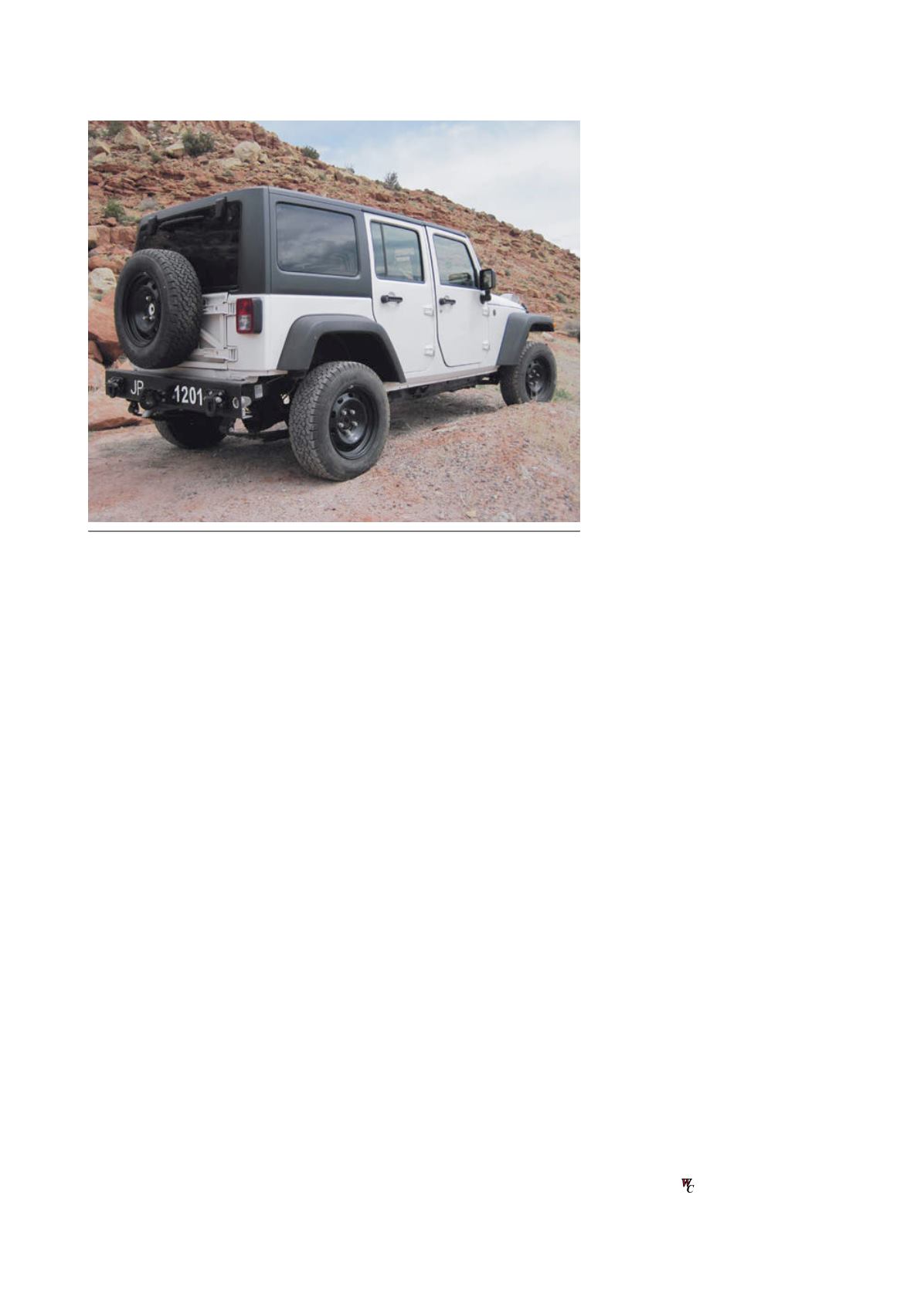

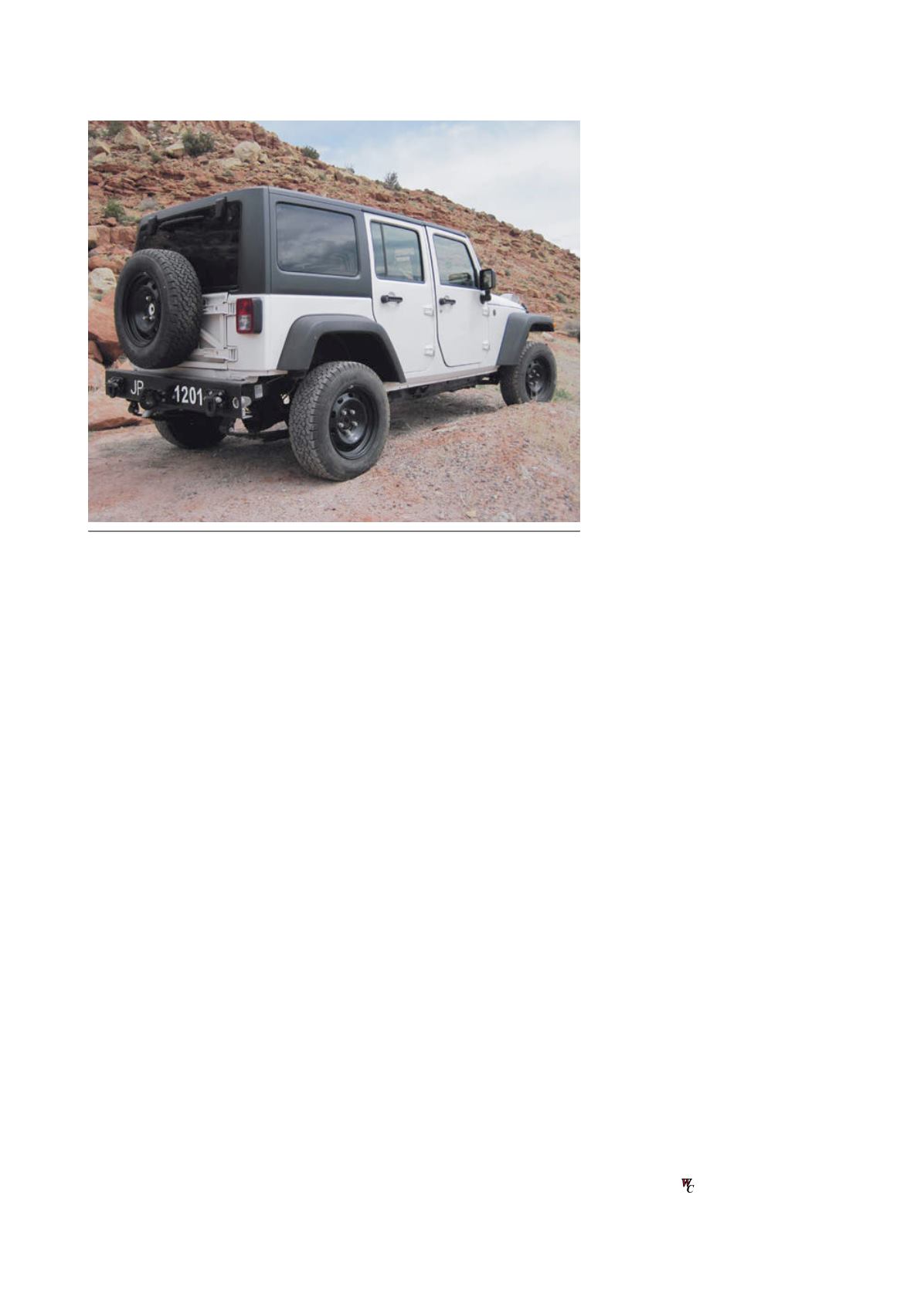

Figure 5. Fully-enclosed air conditioned crew compartments reduce fatigue, while the

Dana 60 rear axle combined with hd leaf springs provides excellent payload capacity.

26

|

World Coal

|

June 2015