gravel at the bottom of the silo and

covers the whole surface. It is also

connected to the piping in the

reclaiming hoppers. Trucks loaded

with liquid nitrogen, can be

connected to a nitrogen evaporator

outside the silo, enabling purging of

the system with nitrogen. This

system has proven to be very

effective.

Alternatively, the reclaiming

hoppers, being a potential entry

point for air, can also be purged with

nitrogen separately. This can be done

by using bottles, allowing purging of

small amounts in the hopper.

At the upper bridge level, foam

sprayers are present to cover specific

parts of the coal surface with a layer

of foam in case of a self-heating

emergency.

A spraying system is installed

above the heat‑resistant conveyor

belt in the basement of the silo to

cool down heated coal.

In the unusual case where

methane is measured, the ventilation

system (2 pcs 50 000 m

3

/hr

ventilators) is automatically started.

The Eurosilo should then be taken

out of operation and a power

shutdown in this silo should be

organised. Up to this day, this has

never occurred.

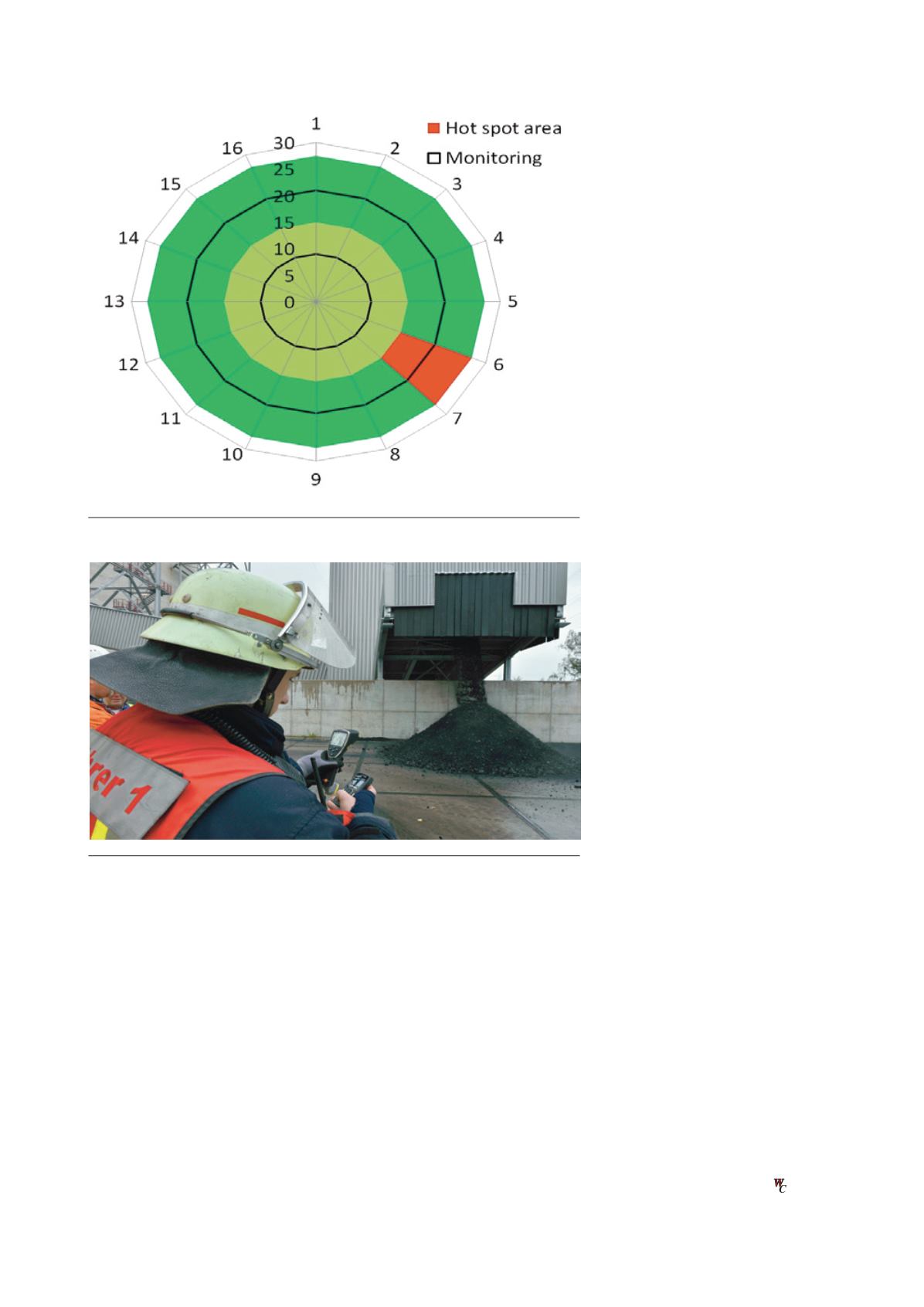

Hotspot measurement

Once an increase in CO is measured,

one can use the indicative screen in

the silos to determine where the

hotspot is. For this, a control screen

displays the approximate position.

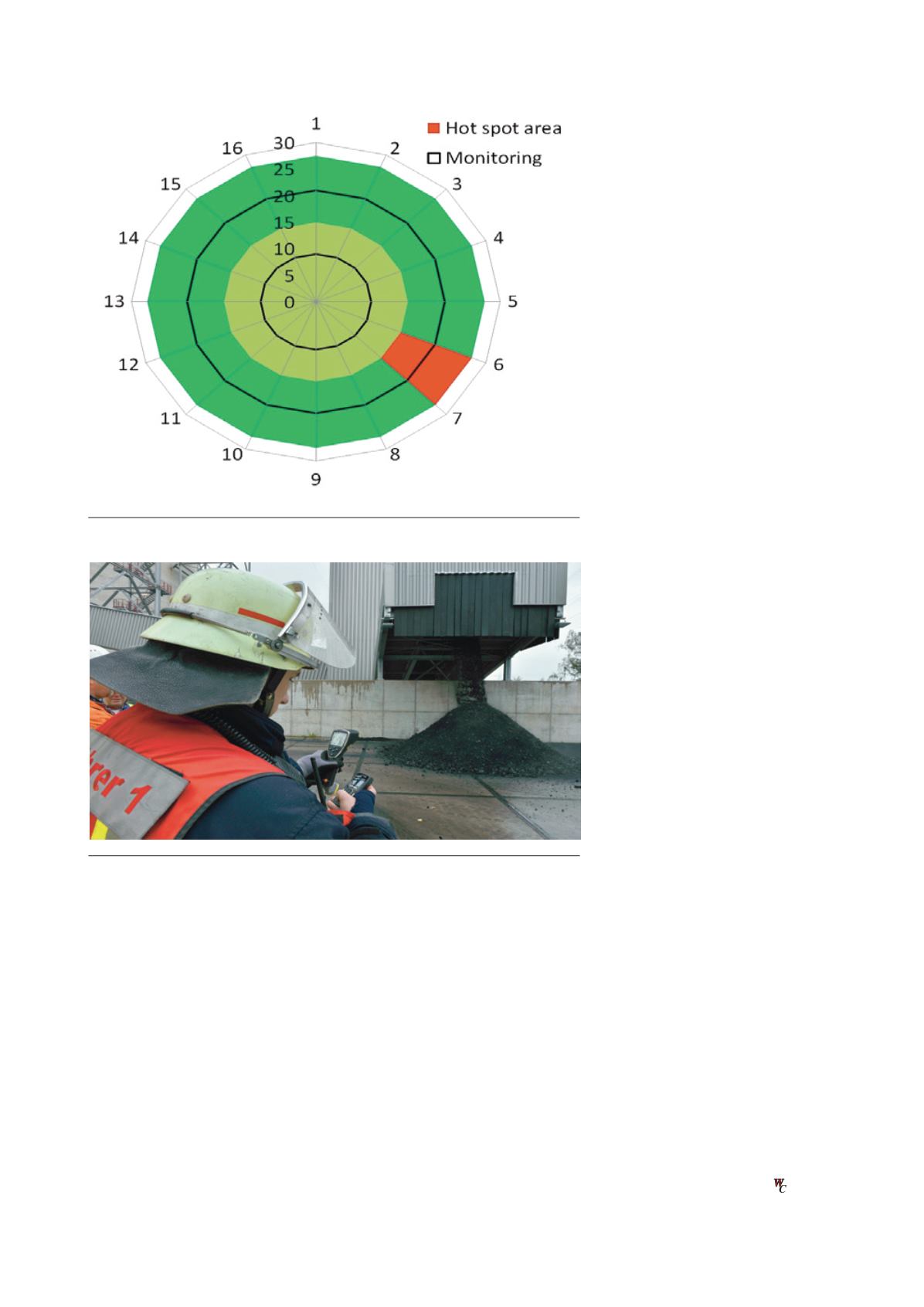

Then, with a thermal imaging

camera, the position can be defined.

Hotspot treatment

Firesorb

®

is a fire-fighting

device‑additive for the firegrade

class A. The liquid-polymer solution

absorbs a multiple amount of its

own weight in water and forms an

adhesive and heat-shielding gel,

which contains no air bubbles but

consists of evenly thickened water.

With the FireSorb-system,

hotspots can be treated. It is only

used in small quantities and only to

counter the hotspot as it reduces the

calorific value of all coal. It can be

used from the rotating bridge, once

the position has been determined.

Experiences with

hotspots

Since the installation commenced full

operation in July 2012, experience

has been gained with the handling

and storing of coal and how to react

when possible challenges arise.

The biggest gain finding has been

that there is ample time to evaluate

the situation and, if a hotspot occurs,

it is not necessary to contact the local

fire department immediately.

Hotspots can be safely managed and

operation of the system is secure and

safe.

A decision on how to counter it is

made in accordance with an

emergency guidebook. To prevent

further damages, hotspots are

removed from the Eurosilo, either by

hand, by discharge system to

emergency loadout or directly in the

day bunkers.

Conclusion

The operating experience with the

Eurosilo system for storing both coal

and FGD-gypsum are satisfactory

and fulfil the expectations.

Determining the position of the hotspot.

Fire fighters with thermal imaging camera monitoring a hotspot.

54

|

World Coal

|

July 2015