power was transferred to the grid in

December 2013.

The power plant is estimated to

use approximately 240 tph of coal at

full load. Coal is sourced through

long-term coal supply contracts and

delivered via the Datteln-Hamm

canal.

Eurosilo was awarded the contract

for constructing the coal storage silos

for the plant.

Coal handling

The plant requires about 2 million tpy

of coal. The coal is sourced from

various mining regions around the

world and delivered to the

Port of Rotterdam by bulk‑carriers.

From there, it is loaded onto barges

(typically four per day) and delivered

to the plant.

The coal is unloaded using cranes

at the plant-owned port and is stored

dust-free in two silos with a 200 000 t

total capacity – enough to operate the

plant for approximately 30 days at

full load. Fugitive dust emissions are

virtually eliminated through the use

of fully enclosed conveyor systems.

A possibility is to convey coal

directly from the cranes via a bypass

to the four day bunkers, where it can

be burned on the same day in the

boiler.

The coal is conveyed from the silos

to four day bunkers that can hold

800 t each in the steam generator

building. It is then pulverised and fed

into Lünen’s 70 m tall boiler.

Coal can be, in case of emergency,

conveyed from the Eurosilos to an

emergency loadout area, where it can

be treated and e.g. afterwards

transported to be re-used.

ESI Eurosilo has carried out the

maintenance and inspections for the

first 2 yr of Eurosilo operation.

As a result of this, experience and

insight was gained in daily operations

of coal silos in general and of the

Lünen installation in detail. This

enabled all parties to gain and share

experiences and optimise the daily

use, operation, maintenance and

inspections of the Eurosilos – building

a close cooperation between parties

and enabling the maintaining of high

standards of working and the

implementation of ideas together.

Coal silos: the details

Why Eurosilos?

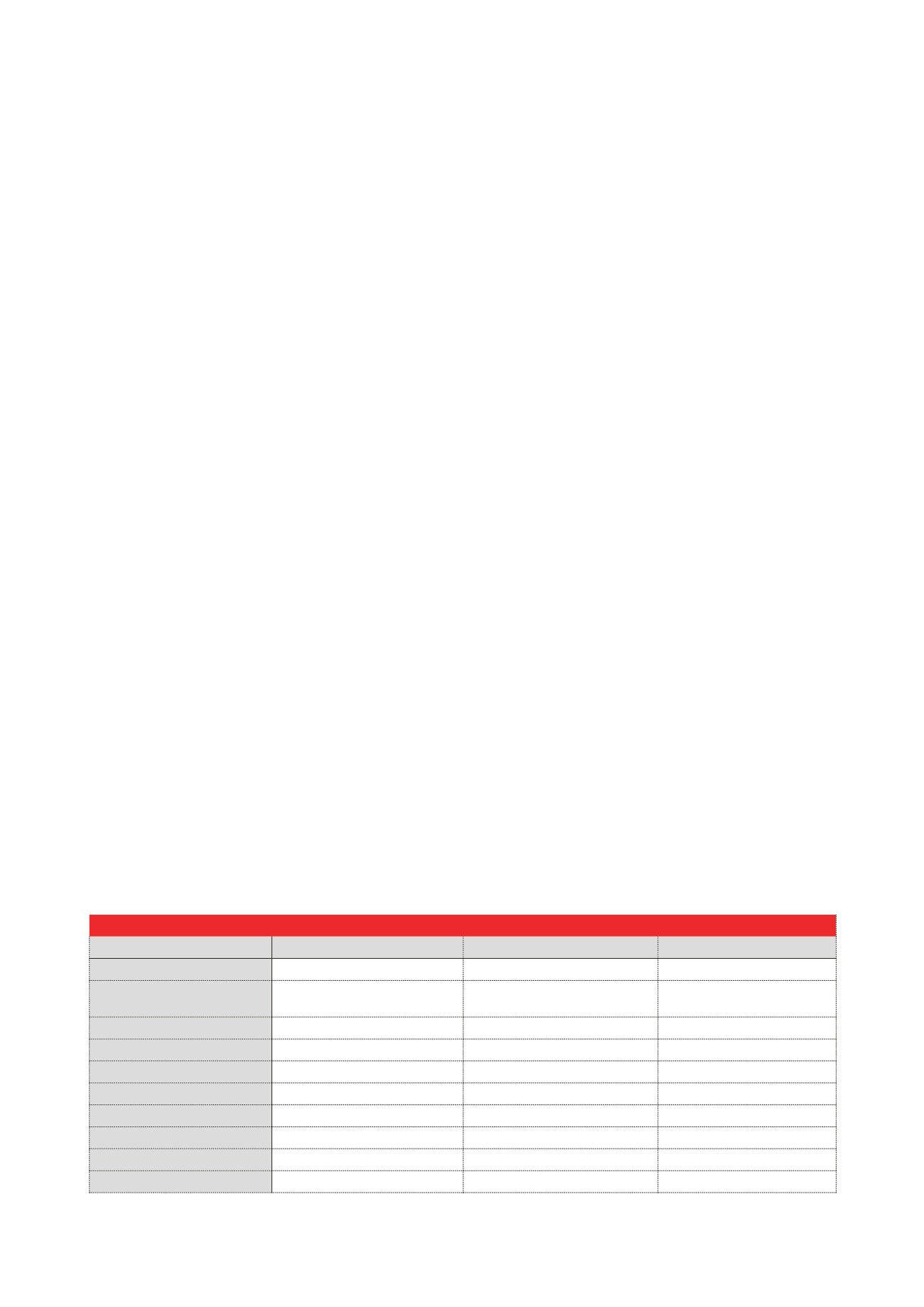

Table 1 shows a summary of

comparisons between options for

enclosed storage systems for the coal.

Eurosilo advantages

The Eurosilo advantages for the

Lünen coal-fired power plant were as

follows:

n

n

Totally enclosed storage.

n

n

State-of-the-art technology.

n

n

Small footprint.

n

n

Fully automated system.

n

n

Meeting the most stringent

environmental protection

requirements (avoids emissions

of respirable dust)

n

n

Coal blending (the values of the

process parameters and the boiler

efficiency depend on the mixture

of coal being burnt in the boiler).

n

n

Lower total cost of ownership in

comparison to other comparable

systems.

Blending of coal

Fuel cost reductions are achieved by

delivering coal of a predetermined

quality to the burners at all times. If a

power plant adopts a dynamic

approach to coal blending (i.e. the

as-fired blends change continuously

to adjust to changing conditions, such

as load, emissions, capacity, coal

availability and expected coal

deliveries), the power plant can

significantly reduce fuel-related costs.

Thus operational flexibility is a

core requirement for cost-effective

power plant operation. To keep

emissions low and to keep an

optimal boiler handling, the mixture

of the coal has to be optimal. This is

achieved by blending, keeping the

ratio from the two silos in a

predetermined rate.

Coal: monitoring,

measuring, managing

Fundamentals for

monitoring

Upon the arrival of the coal, the

temperature of the coal in vessel is

measured by temperature lance and

infrared camera.

Methane, carbon monoxide and

oxygen sensors are present in the

basement and at the overhead

bridge. Depending on the amount of

carbon monoxide (ppm), monitoring

can be intensified and/or preventive

actions can be taken.

Table 1. Comparison of systems

Eurosilo

Circular (dome) storage

Longitudinal (A-frame) storage

Footprint

The most compact system

2 x larger footprint

3 x larger footprint

Filling

Minimal segregation by equalising

auger

Segregation

Segregation

Operation

Fully automated

Partly automated

Partly automated

Oxygen access

Limited

Severe

Severe

Nitrogen purging

Possible through bottom piping

Not possible

Not possible

Structure

Simple slip form

Complex concrete wall

Standard A-frame shed

Coal monitoring

Continuous monitoring by CO Only by infrared

Only by infrared

Fuel management

Fully automated

Partly automated

Partly automated

Dust emissions

None

None

None

Percolation pollution

None

None

None

50

|

World Coal

|

July 2015