contract language. Both ASTM and

ISO have a number of different

sampling methods and, without

specifying, either party can select an

inferior method and still be in

compliance.

ASTM and ISO have standards

addressing both mechanical and

manual sampling of coal. Mechanical

sampling is addressed by ISO 13909

and ASTM D 7430. Manual sampling

is addressed by ISO 18283 and

several different standards in ASTM.

One is manual sampling using

part-stream sampling (D 6609); the

other is stationary sampling in

railcars, barges or stockpiles

(D 6883). Thus, any of the manual

methods in these standards could be

used and still be “in accordance with

ASTM (or ISO) standards”.

Ranking the sampling

methods

Below are the details and ranking of

these various sample collection

methods, which will allow the user

to better select the method they

actually require for their transaction.

In ASTM Standard D 2234, the

standard practice for the collection of

a gross sample of coal, the sampling

methods are ranked from best to

worst in accordance with their

condition. ISO standards are in close

agreement with this. They are as

follows:

n

Condition A: stopped‑belt cut

sampling.

n

Condition B: full‑stream cut

sampling.

n

Condition C: part‑stream cut

sampling.

n

Condition D: stationary

sampling.

The key to understanding why

condition A is the best method and

condition D is the worst method is

that many of the coal characteristics

that are commercially relevant

(moisture, ash, calorific value, etc.)

are not distributed equally in the

different size fractions in the

consignment.

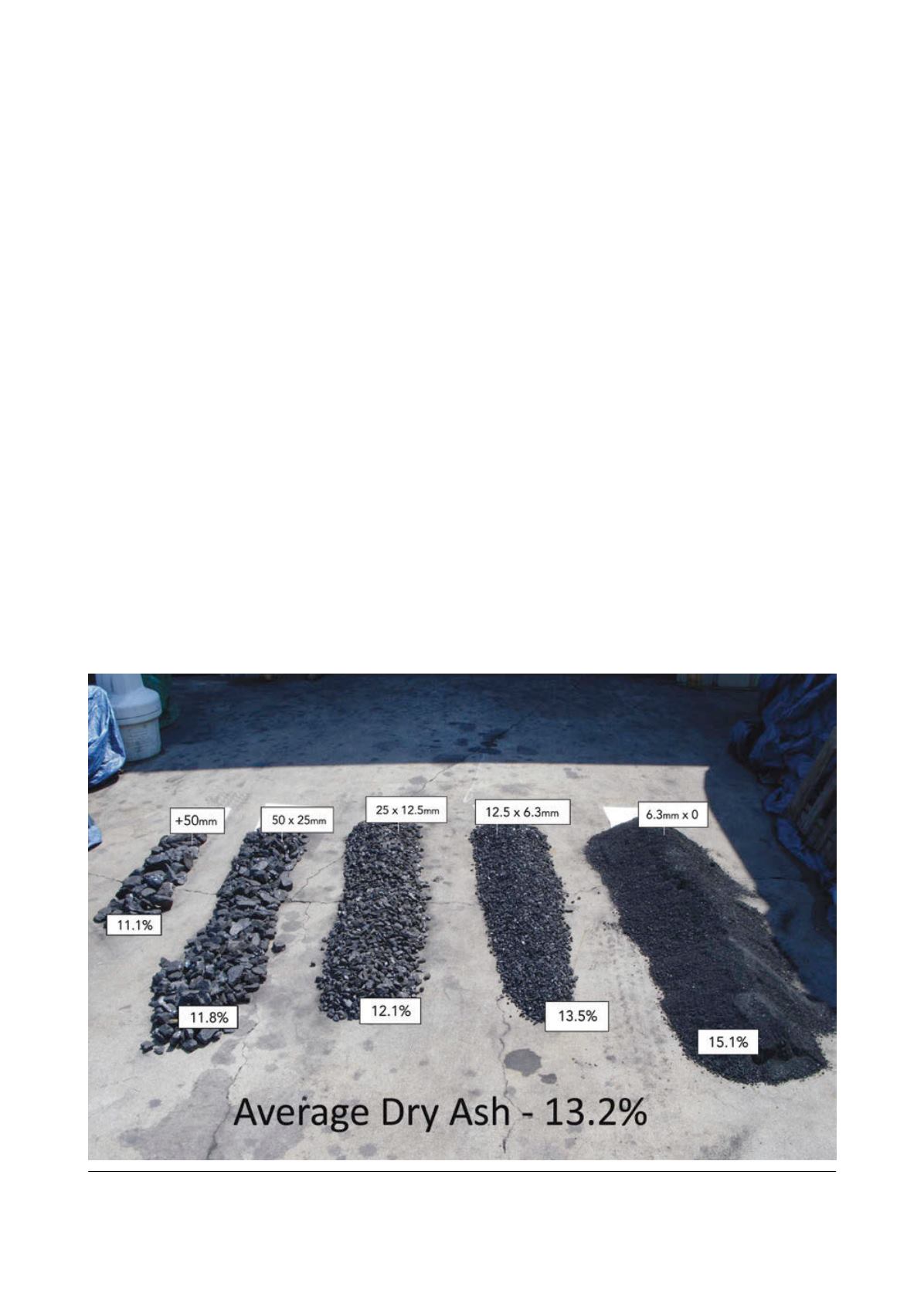

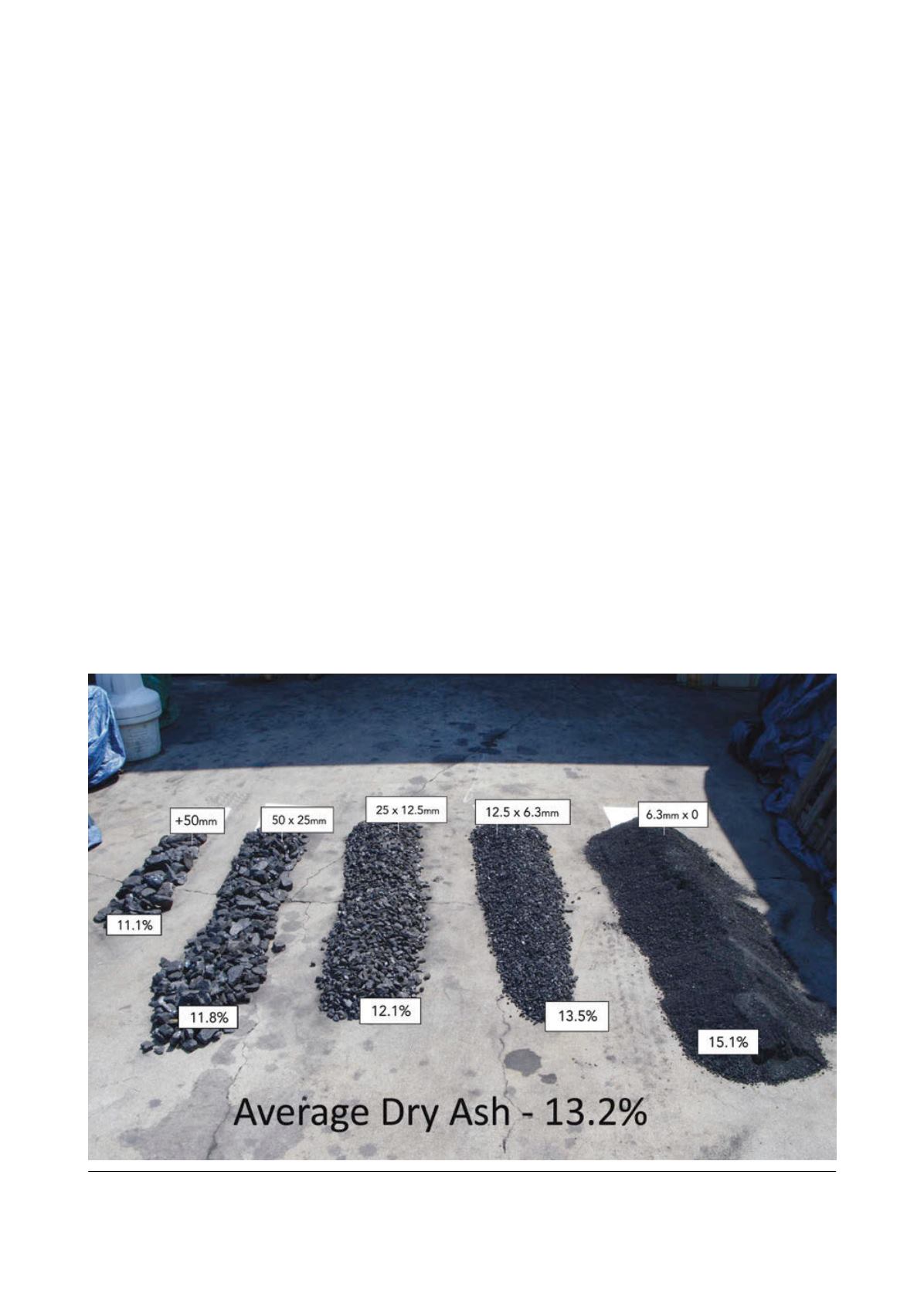

A simple, but important, example

of this is shown in Figure 1. This

shows a sample from a barge of coal

from a single mine, which is first

screened into its various size

fragments and then analysed for dry

ash. The resulting distribution of ash

in the different size fractions is very

typical, with lower ash in the larger

pieces and higher ash in the smaller

pieces. Many coals have wider

ranges compared to the example

here. Ash content and calorific

content are inversely proportional; as

the ash rises the calories fall.

Moisture content is directly

related to surface area, therefore the

same effect is seen in percent

moisture with the fine coal having

much higher moisture content than

the larger pieces. These two

distributions of high ash and high

moisture in the fines have a

compounding effect on one of the

most important commercial issues:

as‑received calorific value.

Due to this disproportional

distribution of important

characteristics in the different size

fractions (true for most bulk

materials), the true objective of any

Figure 1. The ash content changes with different sized particles.

28

|

World Coal

|

August 2015