32 |

Oilfield Technology

June

2015

simple, but highly effective guidance on how to prevent difficult trips

from becoming ‘train‑wrecks’.

Planning

It is unfortunately often the case that inadequate well planning is found

to have played a role in creating the conditions that almost guarantee

problematic trips, and it would be remiss to not highlight some of these

issues.

Resourcing

It is important to avoid late changes in drilling schedules or

under‑resourced teams. Complex wells require time to plan, and

attempts to accelerate or short‑cut the planning process invariably lead

to problems further down the line.

Keypersonnel

Key operator, rig contractor and service company personnel should

have significant experience in similar operations.

Training

Rig teams are better able to respond to problems during trips when

they have been given appropriate training in high angle practices. This

is especially so where operations are progressing from low inclination

E&A wells to development wells, or where new rigs and crews are

mobilising.

Offsetwell review

The starting point for any ERD or complex well should be a

comprehensive offset well review to identify potential hazards. An

often overlooked aspect of such

reviews is the need to quantify

previously experienced friction

factors. As well departures increase,

it becomes more likely that

equipment or other system limits

will be reached, and knowledge

of local friction factors is essential

to ensure an appropriate well

design and adequately specified

equipment.

Wellborestabilitystudy (WBS)

A trajectory specific WBS is preferred

to highlight issues such as low

mud weight window and identify

‘swab down to’ and fracture limits.

This will dictate tripping and casing

running speeds, reducing the risk of

hole enlargement occurring (which

is detrimental to hole cleaning and

tripping).

Drillingprogrammes

It is advised that these include

comprehensive hole cleaning and

tripping procedures; it should not be

assumed that each member of the rig

team has the appropriate experience

on similar wells to adopt the correct

practices.

Holecleaning

Whilst the focus of this article is

tripping, the role of hole cleaning is

so fundamental that it is impossible

not to consider it.

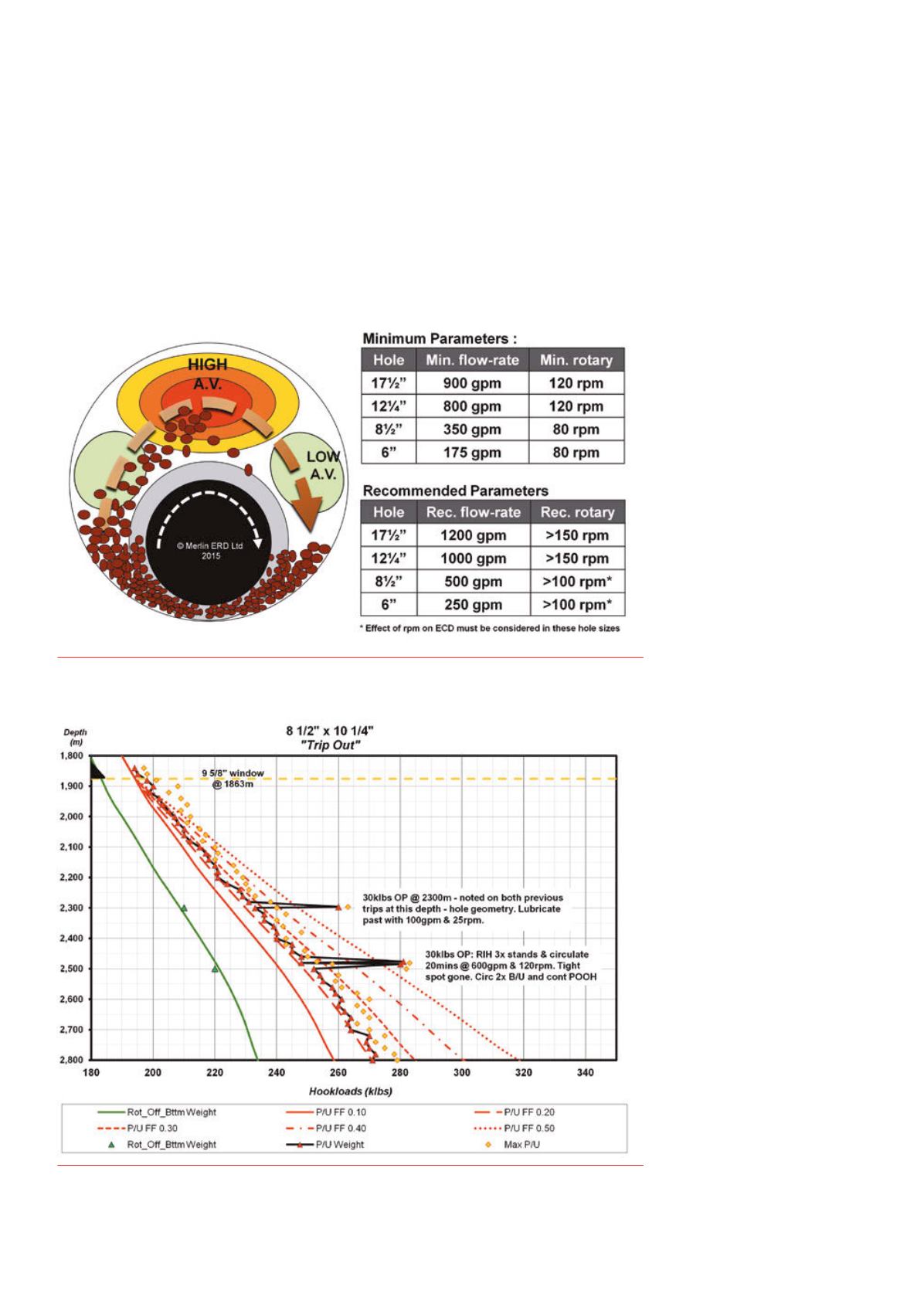

When drilling at high inclination,

drilled cuttings quickly gravitate to

the low side of the wellbore where

they accumulate to form a cuttings

bed. As drilling progresses the

cuttings bed achieves an equilibrium

height, dictated in part by the rate

of penetration (i.e. the amount of

material being added) and the flow

rate, drill string rotary speed and

mud parameters, which influence

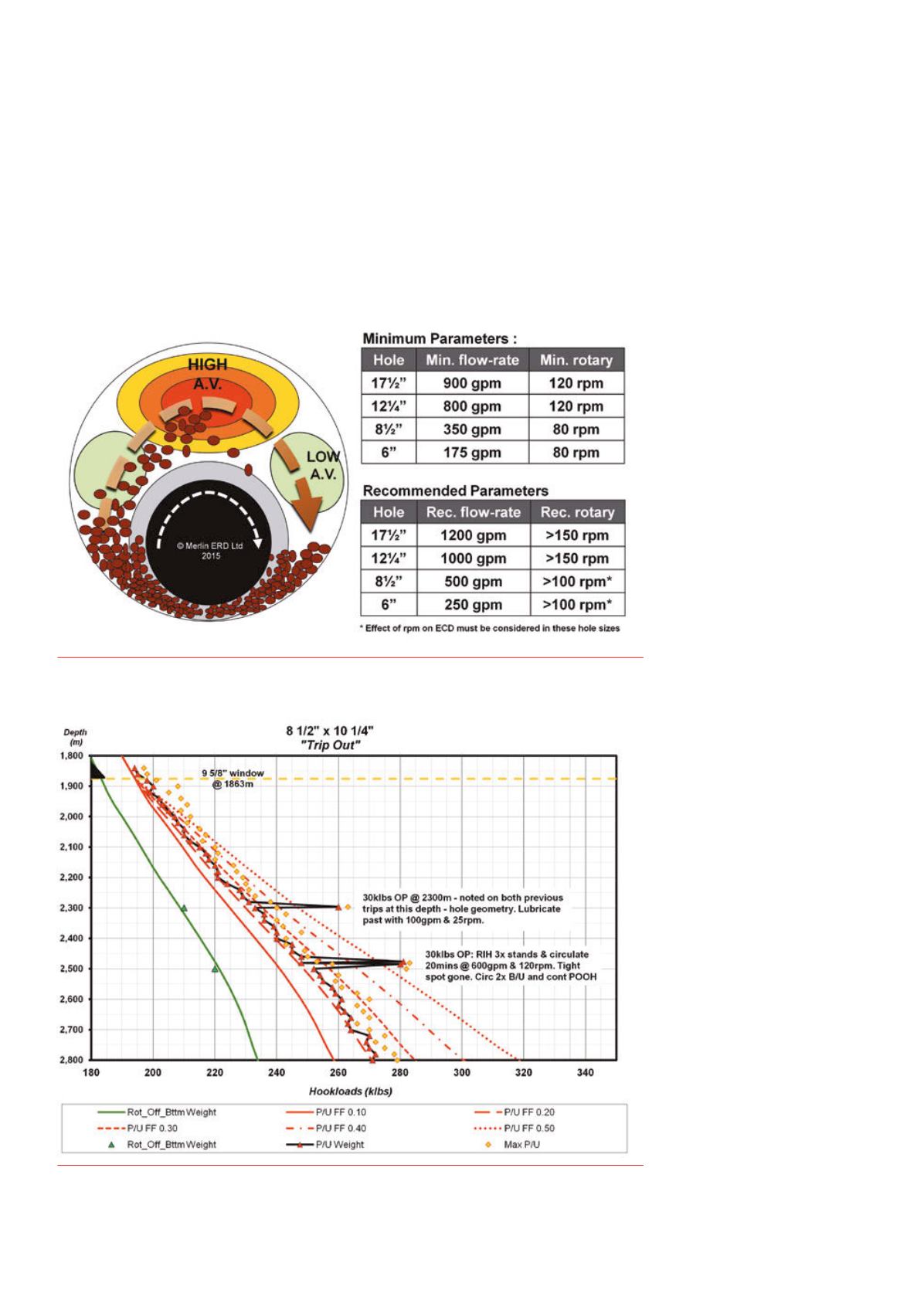

Figure 2.

Torque anddrag roadmap example: plottingactual hookloads on top of theoretical curves allows the

driller to quickly identify departures in trendand take the appropriate remedial action. This simple but effective

technique shouldbe performed routinely on complex and ERDwells.

Figure 1.

Hole cleaning thresholds: optimal hole cleaning occurswhendrillingparameters remainabove

‘recommended’. If parameters dropbelow ‘minimum’ then hole cleaningmay be significantly compromised

and increased trip risk shouldbe anticipated.