70 |

Oilfield Technology

August

2015

Workovers are all the more essential as expanded regulatory

criteria mean existing assets may no longer meet well integrity

requirements. New technologies are emerging and existing tools

are advancing to meet these needs of the industry.

Well designs are improving to incorporate pre‑planning

for future well intervention needs, but many older assets,

even absent such provisions, can offer an excellent return on

investment if economical intervention methods are available.

These operations can often be extremely challenging; however,

as there is typically a high level of uncertainty in regards to

the condition of the casing, cement, and other downhole

components.

As wells age, failures can occur involving the complex

hardware installed to control production or injection flows.

Quite often, a component leak can cause sustained casing

pressure in the annulus. The economics of using a rig to perform

interventions on an older well can be difficult to justify, so

wireline is often used for such interventions. Reliable wireline

setting options are available for use in deploying an inflatable

packer to locate and isolate a leak. For highly deviated wells,

the system can also be deployed with a wireline tractor.

Riglesssettingmethodsareadvancing

TAM International’s slickline setting tool SlikPak has been

available for several years, enabling innovative intervention

approaches. Since then, the ongoing demands of deepwater

development have driven the need for technology that can

perform in deeper, hotter well conditions. TAM is preparing for

the commercial release of its next‑generation setting tool, which

is currently undergoing field trials. This new technology will

significantly increase the performance envelope and capabilities

of inflatable packers. Bridge plugs can also be set with the new

setting tool.

The inflatable setting tool system consists of a

self‑contained battery power unit and a downhole pump, which

inflates the bridge plug or packer with wellbore fluid or with

clean fluid carried in onboard reservoirs from the surface. The

standard packer or plug sizes available for routine deepwater

interventions using this tool range from 2

⅛

‑ 3 ¾ in. OD, with

larger sizes available when required. The new system is rated for

bottom hole pressures up to 15 000 psi and 300˚F.

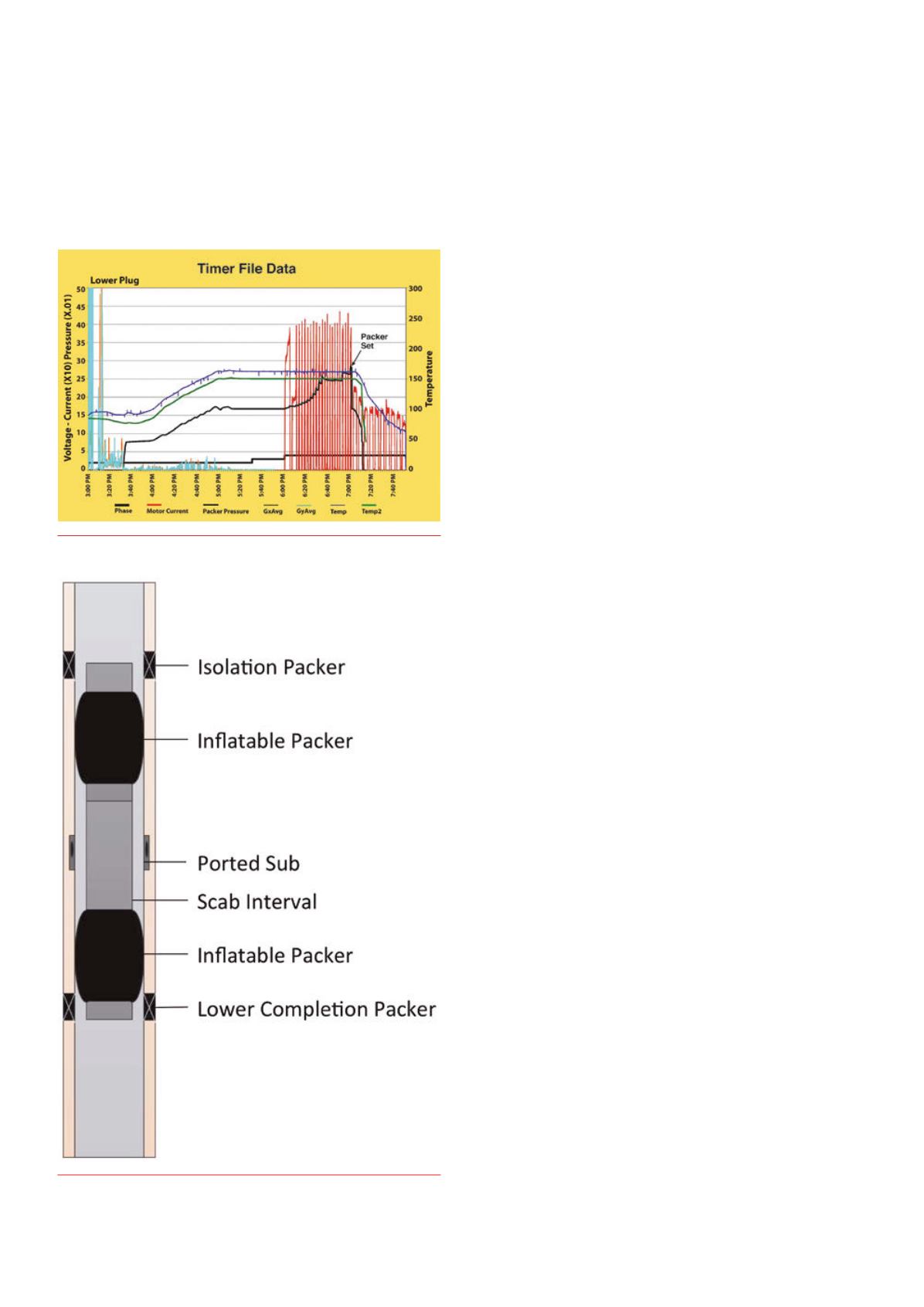

An onboard downhole computer controls the downhole

setting sequence to ensure proper setting pressures are

achieved and to prevent premature setting. Once the computer

has determined that the packer can be set, it starts a motor that

controls a high‑pressure pump to inflate the packer. Downhole

data is captured, downloaded, and analysed to verify all

systems performed properly downhole.

One of the limiting factors for an inflatable packer is the

amount of setting pressure possible inside the element. Higher

inflation pressures mean better holding forces and ultimately

higher differential pressure ratings. When setting inflatables on

pipe, this setting pressure is limited only by the rating of the

packer element. However, when setting inflatables on slickline

or wireline, the limits on setting pressure are determined

by the capabilities of the downhole setting tool, such as the

capacity for pump pressure output or the ability to increase

pressure by pulling tension on the line. The pressure limits of

existing slickline setting tools available on the market have

been acceptable for a wide variety of applications. But the

new technology setting tool will significantly increase the

inflation pressure available to inflatable elements downhole in

through‑tubing applications.

Element capabilities increasingtomeetmarket

needs

In conjunction with the new setting tool, inflatable element

technology is also evolving to provide a greater working

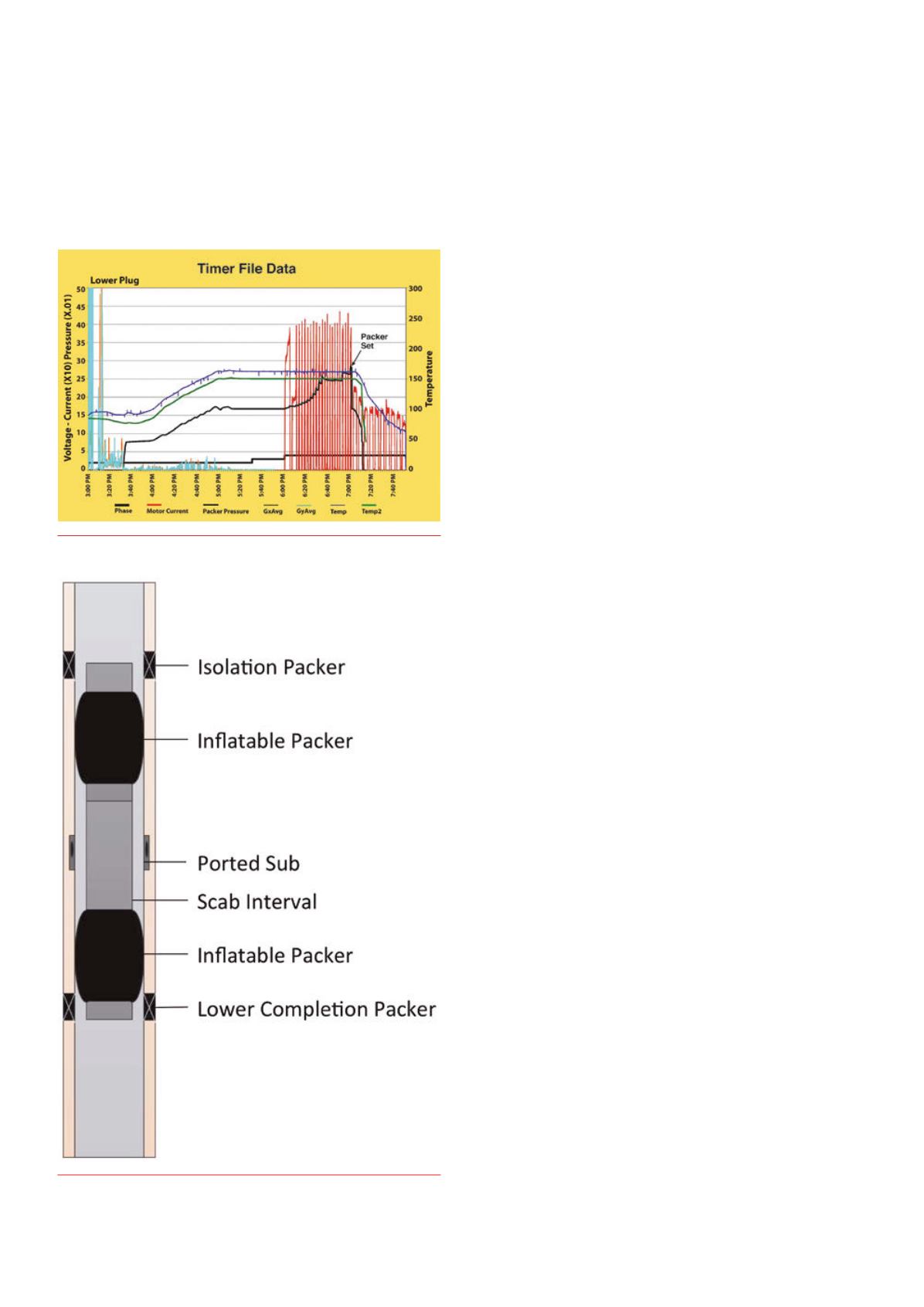

Figure 2.

Illustration of Scab Liner Installation.

Figure 1.

Record of setting sequence.