August

2015

Oilfield Technology

|

61

Ì

Ì

The new application enabled assessment of all possible PT

combinations. Instead of just evaluating the system setup actually

configured, all possible permutations were tested, and the best

candidate was highlighted. This capability is crucial to reach the

best decoding performance without wasting time or even creating

NPT.

Fieldexperiencewith improvedsystem

In recent years, the demand for HSMPT has continuously increased.

The first test for the improved HSMPT system occurred a couple of

years ago in the most challenging region with high-viscosity OBM and

made it possible to deploy the improved system on all installations

where HSMPT was in demand. The improved system continued to

evolve and the decoding process was further automated and simplified

to the point that the jobs were supported by the standard rig teams. At

that point, and with the good track record of the improved HSMPT, the

use of the system increased on several of rigs as well as the confidence

in the positive results.

The improved HSMPT system has been used on many different

offshore installations in challenging deepwater environment with

high-viscosity OBM, and the TS could be reliably found on all of the

rigs, under almost all drilling conditions, with all mud systems and at

all depths. Especially significant improvements were achieved in the

smaller diameter hole sections.

For a more-detailed evaluation of the field performance, a subset

of data sets considering more challenging conditions is assessed.

Figure 3 shows the automatic detection performance for the TS.

The new system adjustments result in a clear improvement over the

previous system. This performance is considering single instances

of the TS without manual interaction needs. Together with the

consideration of mostly challenging conditions, it shows the potential

of the new system.

An operator placed a high priority on using HSMPT in a reservoir

section offshore, after having previously experienced significant quality

improvements in a drilled reservoir in the same field, due to increased

quality of real time data supplied while drilling. The service company

committed to run with high-speed telemetry in this challenging

environment and relied on the new features of improved HSMPT system

tomake the difference. A BHA similar to the one used in previous

reservoir sections was also deployed in this section. This BHA included

a steering unit along with the following services: drilling dynamics,

azimuthal gamma, resistivity, azimuthal density, porosity, nuclear

magnetic resonance, acoustic and formation pressure. The oil-based

mud used was also similar to that of the previously drilled sections,

having a density between 11.0 ppg and 11.8 ppg and a plastic viscosity

between 18 cP and 22 cP. A shallow-hole test was performed, and

good calibration parameters were generated from the first transmitted

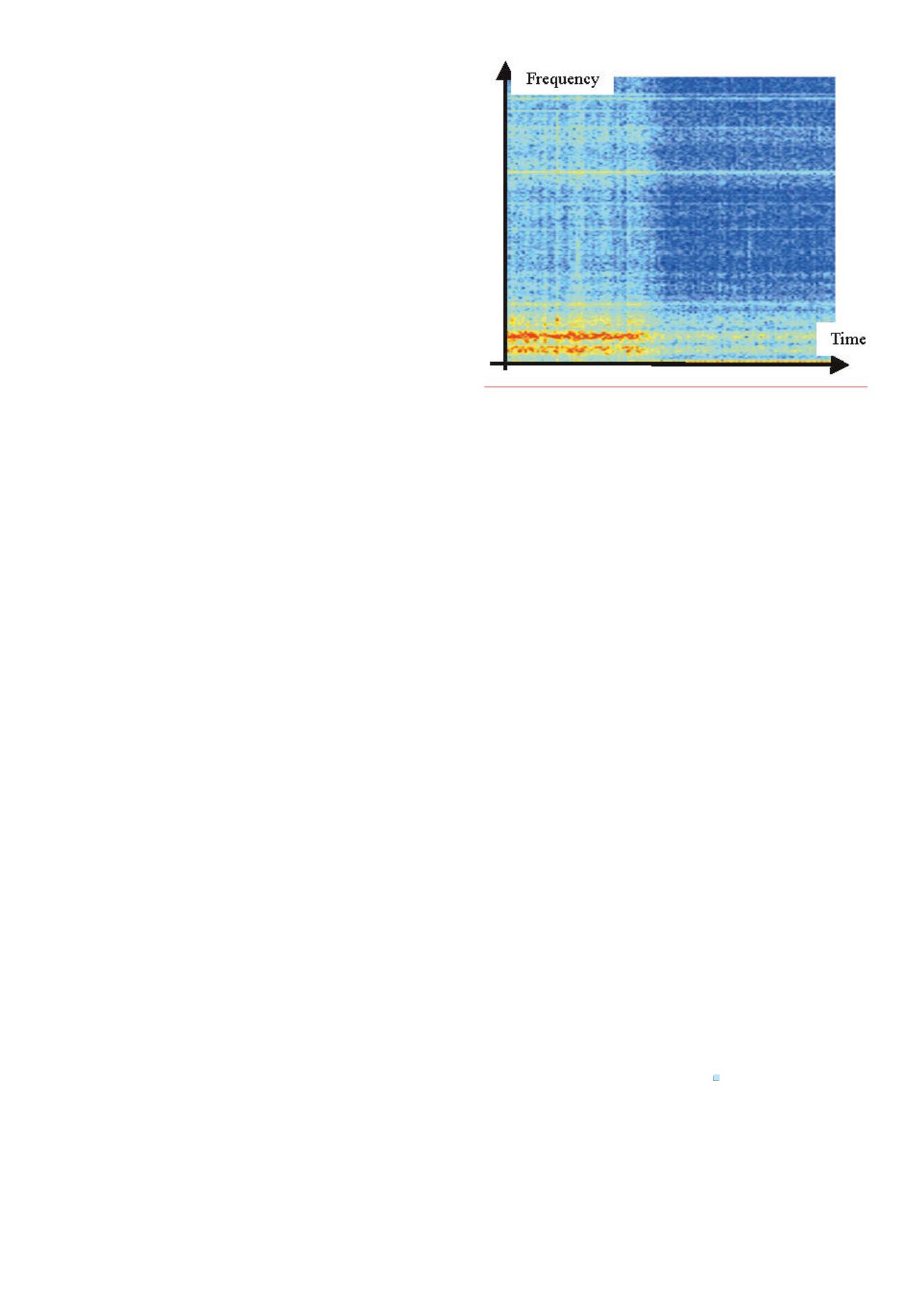

training signal. Figure 4 shows a spectrogramof the first set of data

from that shallow depth, where strong signal content is depicted in

red, while weaker signal content is shown in blue. The high-frequency

signal components are still visible. This set of coefficients delivered good

decoding performance while drilling the first stands.

By utilising the new HSMPT, the longest slim hole section of this

field was drilled. It covered over 2000 m of reservoir section. More than

90% of the reservoir section could be drilled with a high data rate.

Drilling this section was very challenging due to high torsional and

lateral vibration levels, which caused considerable downhole drilling

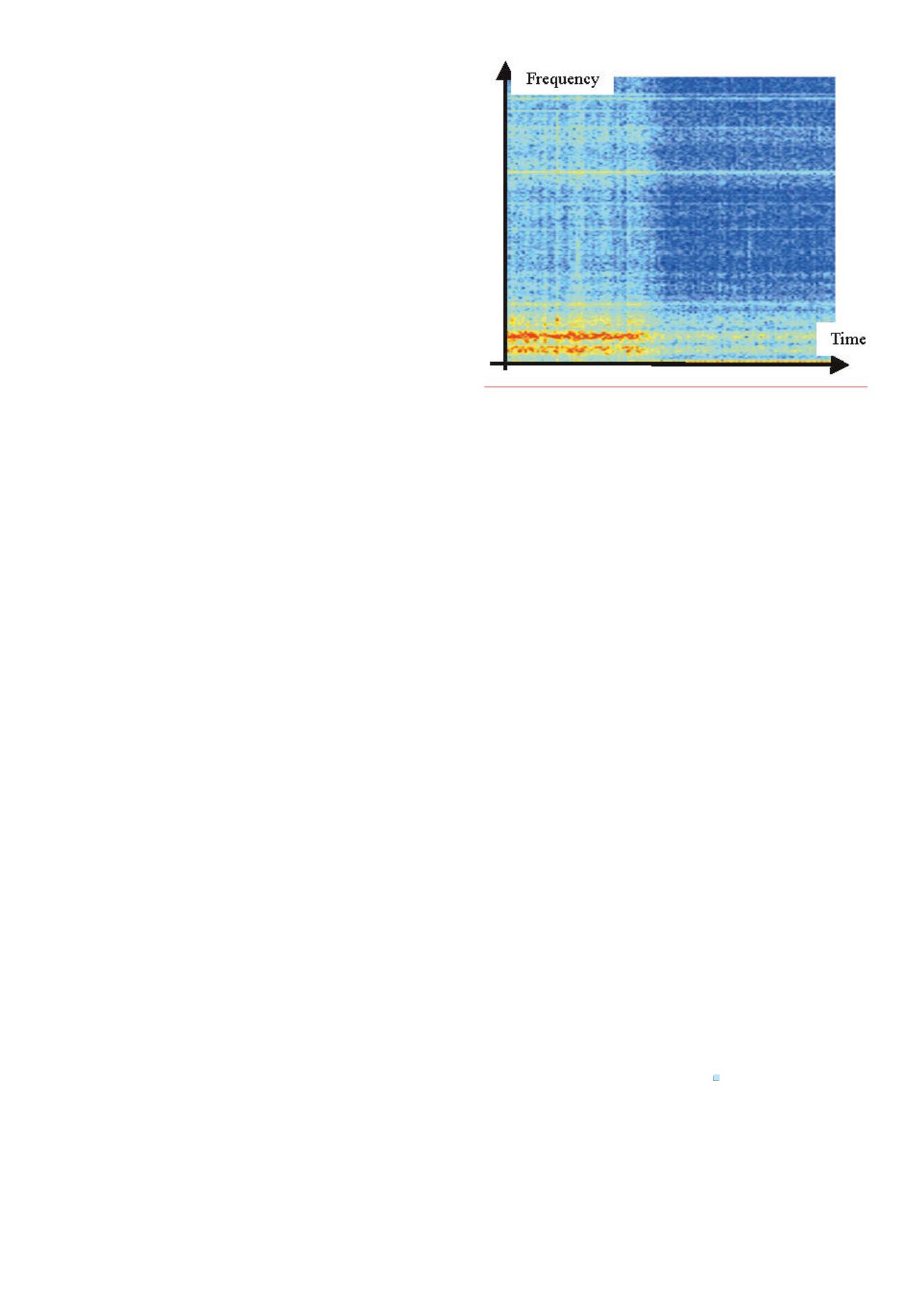

noise. The impact of high stick/slip values on the MPT signal can be

seen in Figures 5 and 6. A high-energy, low-frequency wave interfered

with the telemetry signal and had to be cancelled out. Both figures

show approximately the same content. The distortions of the pressure

signal created by stick/slip can be clearly seen in Figure 5 in the time

domain. Figure 6 shows the impact on the frequency content of the

MPT during this time period. Stick/slip adds as a dominating distortion

in the spectrum, weakening higher frequency contents.

The advanced filtering and processing methods introduced by

the improved HSMPT systemmade it possible to deliver sustainable

HSMPT data rates even with high vibration levels. The improved

training signal detection rate allowed for more frequent updates

of the adaptive filters, which in turn led to the robust delivery of

the required data rate. The success rate of the training sequence

detection reached 95%.

Conclusions

HSMPT systems enable the drilling of wells in conditions where

high-density directional, downhole pressure, drilling dynamics and

formation evaluation data is critical. However, there are still challenges

with the reliability of HSMPT systems.

The improved HSMPT system addresses these reliability issues and

provides:

Ì

Ì

Significant improvement in the detection of the TS with

introduction as new hardware and software solutions and

automation of the detection process.

Ì

Ì

Tremendous improvement of the reliability of the TS detection in

previously challenging environmental conditions.

Ì

Ì

Automatic evaluation of the new coefficient sets for decoding

filtering, even in constantly changing communication channel

conditions.

Ì

Ì

A database of coefficient sets to assist the FSE through automated

saving of the sets with corresponding additional information.

Ì

Ì

The assessment of all possible pressure transducer combinations

with testing of all possible permutations and highlighting the best

candidate.

The improved HSMPT system is successfully tested in several

deepwater areas as with WBM and OBM systems and demonstrated a

significant increase in reliability of HSMPT.

References

1.

Proakis, J. C., ‘Digital Communications, fourth edition’,

Singapore: McGraw-Hill, (2001).

2.

Klotz, C., Bond P. andWassermann I., et al., ‘A newmud pulse telemetry system for

enhanced MWD/LWD Applications’, Paper SPE 112683 presented at the IADC/SPE

Drilling Conference, Orlando, (4 - 6 March, 2008).

3.

Shen Y., Su Y., Li G., Li L. and Tian S., ‘Numerical modeling of DPSK pressure signals

and their transmission characteristics inmud channels’, PetroleumScience 6 (3),

(2009): pp. 266 - 270.

Figure 6.

Stick/slip severity change and impact on the power density

spectrumof the pressure signal. Reddepicts strong signal content, blue

showsweak signal content.