18 |

Oilfield Technology

August

2015

yields an energy density that is 1.5 to 5 times higher than the other

chemistries for a given volume. This is highly desirable when size and

weight matter and long run time is also required. As a comparison,

the chemistry chart (Figure 4) shows SLA on the bottom left with a

volumetric energy density value of approximately 125 Wh/l and a

gravimetric energy density of approximately 50 Wh/kg, (maximum

values). Today’s Li-ion chemistries provide approximately 700 Wh/l,

5.6 times that of SLA and approximately 250 Wh/kg, five times that of

SLA respectively, (maximum values).

Lithium iron phosphate technology (LFP), a variant of lithium-ion,

while not as high as conventional Li-ion provides an increase over SLA

at approximately 350 Wh/l and 120 Wh/kg. LFP may not yield as much

energy but has other characteristics that are very positive in relation

to life and performance.

Lithium-ion chemistry develops voltages in the range of 3.3 V to

3.7 V per cell, in comparison to 2.0 V per cell for a lead acid chemistry

and 1.2 V per cell for both nickel cadmium and nickel metal hydride.

The higher voltage and the higher energy density enables higher

voltage assemblies with fewer individual cells, which helps keep size

and weight down.

A side by side comparison of features and benefits of the various

chemistries can be seen in Table 1; Li-ion chemistry is not only higher

in energy density but also offers:

Ì

Ì

Much longer product life (cycle life).

Ì

Ì

Greater capacity at end of life (80% versus 60% SLA).

Ì

Ì

Faster recharge time for improved productivity.

Ì

Ì

Excellent storage capacity retention and recovery.

Ì

Ì

Wide temperature range for extreme temperature

environments.

Lithiumbatteries inuse

It is hard to argue with the many benefits of lithium-ion

and, as a result, many exploration contractors have moved

to or added large lithium-ion batteries to replace the lead

acid batteries in their inventory. Larger Li-ion batteries

are available in capacities ranging from 20 Ah to 50 Ah and

in some cases can be joined in a parallel configuration to

provide up to 100 Ah capacity that can be used as direct

replacements to commonly used lead acid batteries. Some

offerings are specifically created for the seismic market

designed with fully sealed thick plastic cases, specialised

connectors and built to interface directly with OEM seismic

devices, while others look a lot like a standard SLA battery

that can be housed in a waterproof case for use outdoors

(Figure 5).

Li-ion packs are also designed into smaller assemblies

and are found paired with or built into the seismic

recording device. Today, Li-ion batteries are used as the

main power source for all wireless land seismic acquisition

systems.

Offshore seismic exploration equipment, such

as towed and seabed equipment, utilise a variety of

chemistries for portable power. Some of the chemistries

used are SLA, alkaline, nickel metal hydride, lithium

primary and Li-ion. Devices that are tethered and towed,

some resembling torpedoes, have external or internal

batteries depending on the device. In some cases, the

devices are powered by SLA batteries mounted onboard a

ship that provides power through a tethered connection to

the device. Other towed devices have internal batteries to

provide power; these internally powered devices typically

utilise nickel metal hydride or Li-ion batteries. Since size and weight

are less critical to offshore devices than land seismic equipment, not

all devices have converted to Li-ion technology, as is the case with

land use equipment.

Large seabed devices are often deployed for months at a time

and therefore, do not have the luxury of recharging. Due to the nature

of use, non-rechargeable primary cells are typically used in these

applications and adapting to rechargeable Li-ion technology is not

likely to occur.

Wireless nodes are an early adopter of Li-ion technology to reduce

size, weight and to provide long run time. Wired nodes are likely to

remain the choice in open areas, such as deserts, where cable can be

quickly laid using a vehicle, and where drifting sand can swallow up

wireless units and the valuable data they hold. The adoption of large

Li-ion batteries to power the cabled systems is growing.

The evolution of seismic data-gathering techniques will continue

to require battery power as its main source of energy, and Li-ion

technology will continue to be the best choice as it continues to

evolve in its energy density and performance characteristics.

References

1.

Crice, D., ‘Seismic Surveys Without Cables’, GEO Expro, (2011).

2.

Durham, L. S. ‘A Wireless Future? Cables Can Tangle Seismic Plans’,

AAPG Exployer, (2007).

3.

‘ge0physicsrocks’ 3D Seismic. Retrieved from

/

watch?v=hxJa7EvYoFI, (August 29, 2011).

4.

Marine Seismic Methods. (2011, December 11). Retrieved from

:

/

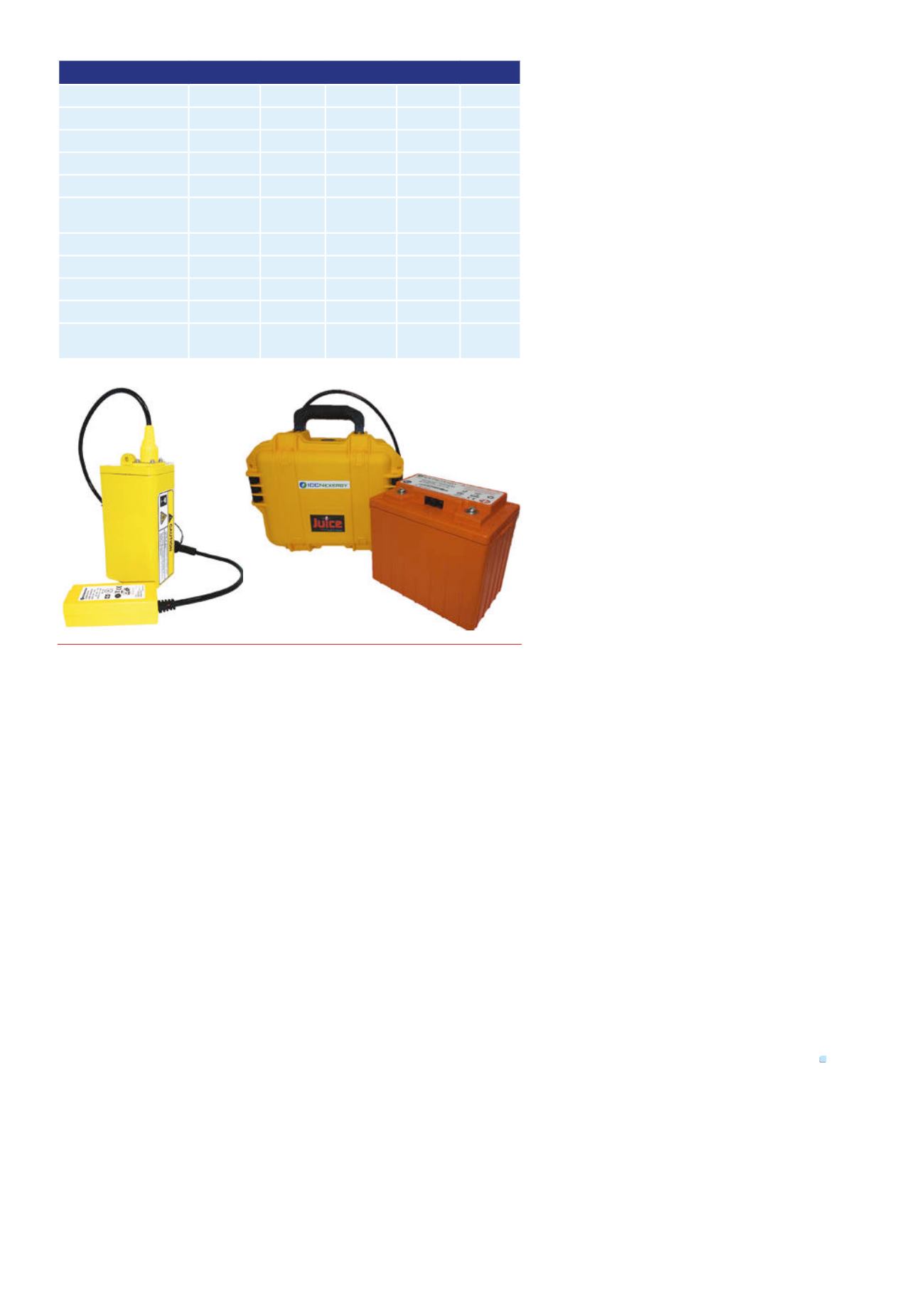

Table 1. Chemistry comparison.

Lead acid Ni-Cd

Ni-MH

Li-ion

LiFe

Cell voltage

2 V

1.2 V

1.2 V

3.6 - 3.7 V 3.2 - 3.3 V

Energy density (Wh/Kg)

50

70

110

250

120

Cycle life

250

500 - 1000 500 - 1000 500 - 1000 >2000

End of life capacity

60%

80%

80%

80% 80%

Capacity rating

method

C/20

C/5

C/5

C/5

C/5

Charging time

6+ hrs

1+ hrs

1.5+ hrs

2+ hrs

1+ hrs

Weight

5X

3.5X

2.3X

1X

2X

Size

5X

4X

1.75X

1X

2X

High temp survivability

1X

2X

1.5X

2X

2X

Long term storage

recovery

1X

1.5X

1.5X

2X

2X

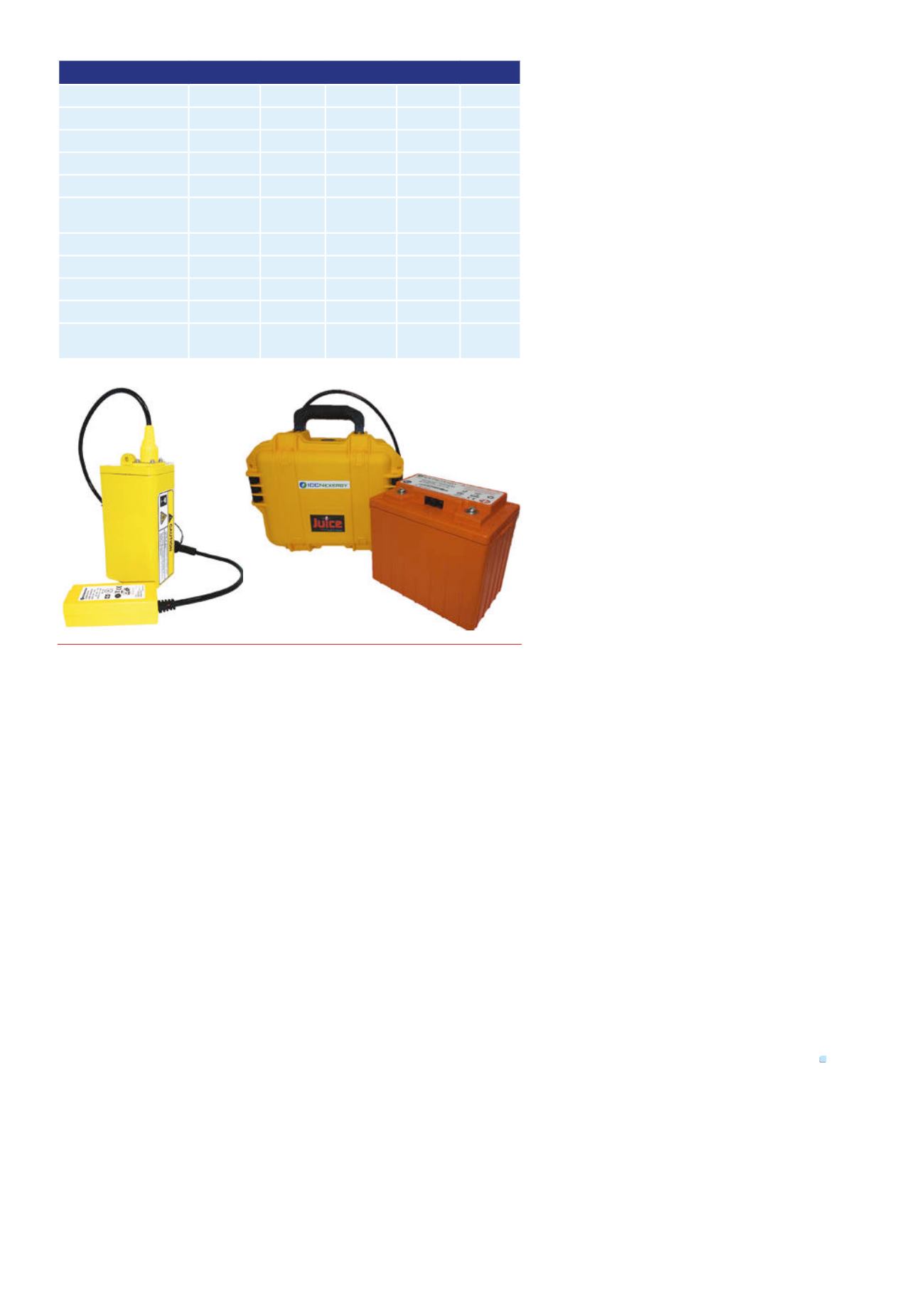

Figure 5.

(Left) SS18 12V 18Ah seismic battery. (Right) U1LiFe batterywthwaterproof

juice case.