at the hang off clamp. Handling quad joints from 4 - 36 in.

dia. and operating from 46 - 96˚, the tower can comfortably

lay in both shallow and deepwaters. An integral bulky item

handling system and adjustable stinger also contribute to

the high functionality and versatility of the system. The

key design drivers through throughout the development

were the efficiency of pipe handling operations to ensure

functionally safe equipment combined with low cycle time

and weight optimisation. By working closely with the client

throughout the process and utilising skills on both sides, this

has been achieved.

Now having subsequently been involved with the

design, manufacture and delivery of numerous and varied

pipelay systems and equipment, IHC Engineering Business

is in the advantageous position of being able to draw on

first-hand in-house knowledge to provide efficient, bespoke

engineering solutions to cover all laying requirements.

In 2014, IHC Engineering Business celebrated the contract

award for a next generation J-lay system to be installed on

client Petrofac’s new vessel, the

JSD6000

.

JSD6000 J-lay partnership setting new

standards

The offshore construction industry prides itself in never

standing still. The need to innovate in the constant search

for improvement and efficiency has, in a climate of

drastically reduced oil prices, never been more important.

As producers and global oil majors have seen revenues

shrink, the drive to reduce costs throughout the supply

chain is being felt by all involved. In parallel with the

downward pressure on prices and costs there has been a

sharper focus on the environmental impact of the global

energy industry.

The impact on new exploration and construction costs

has been particularly challenging and contractors are keen

to react positively. Key to reducing construction costs

and minimising the impact on the environment is a new

generation of safer, greener and more cost-efficient offshore

construction and support vessels.

Royal IHC is almost uniquely placed, as both shipbuilder

and mission equipment specialist, to react to the challenges

faced by the global industry it serves. The pipelay market

in particular is feeling pressures on costs, efficiency and

environmental impact as never before. The solution

is innovation and investment in a wide range of new

technologies to improve performance in all areas.

Petrofac – the international construction services

provider to the oil and gas industry – has initiated a huge

investment programme in offshore construction assets.

Petrofac’s

JSD6000

pipelay and heavy-lift vessel is currently

in build with a global supply chain for vessel and mission

equipment. IHC Engineering Business – IHC’s pipelay,

cablelay and subsea equipment specialist – were selected

by Petrofac to design and build a truly state of the art J-lay

system for deepwater pipelay.

Equipment choice

Any offshore deepwater pipelay asset is without doubt a

complex and valuable tool within an operator’s portfolio.

They need to be flexible and carefully designed to

allow the maximum usage to recoup the considerable

investment that has been made. This leads to vessels

generally being developed with a range of optional

configurations.

Some vessels concentrate on vertical lay but with a

range of equipment allowing a variety of lay speeds for

different water depths and pipe diameters.

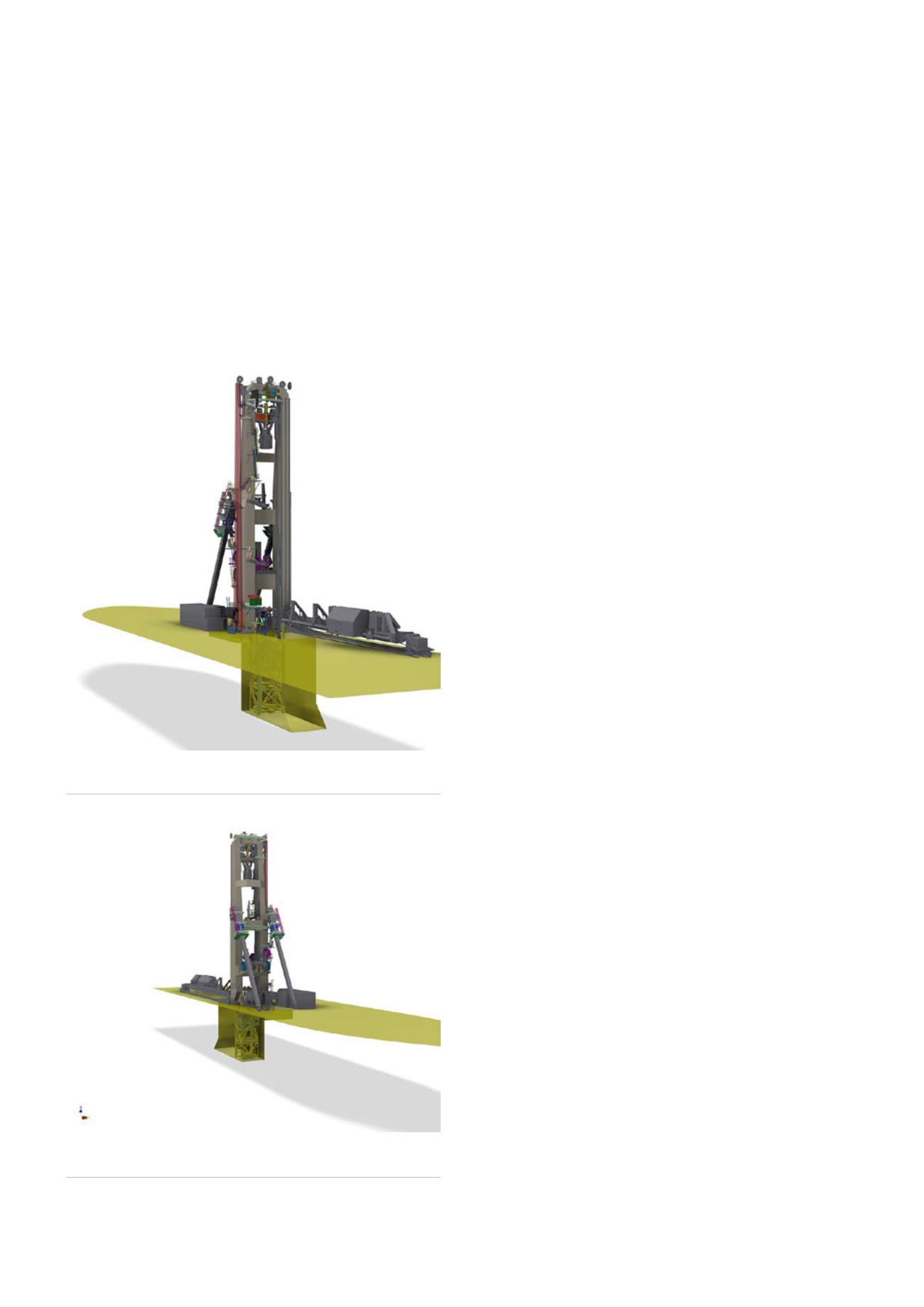

Figure 1.

Petrofac

JSD6000

J-lay System concept (view from aft

side).

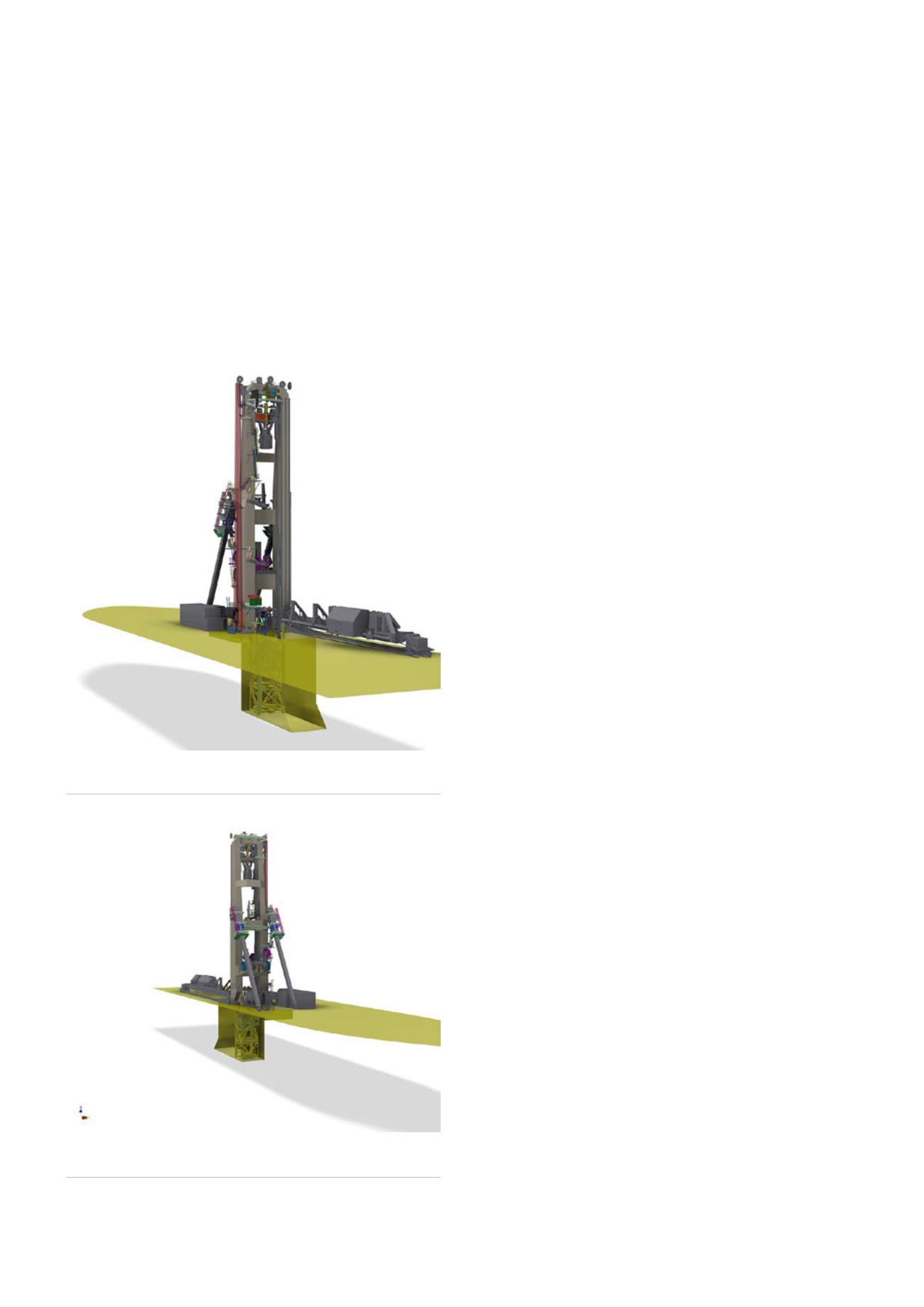

Figure 2.

Petrofac

JSD6000

J-lay System concept (view from

forward side).

90

World Pipelines

/

JULY 2015